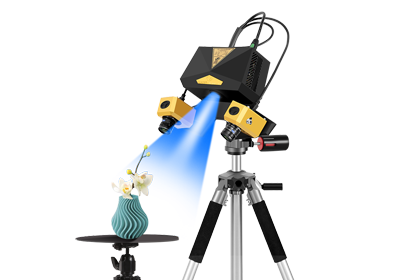

White Light 3D Scanner

- High-precision: 0.05-0.1mm

- High speed scanning: 500,000 points/s

- Stand off Distance:650 +-250mmm

- Wide and macro scanning can be controlledCan work outside in bright light

White Light 3D Scanner

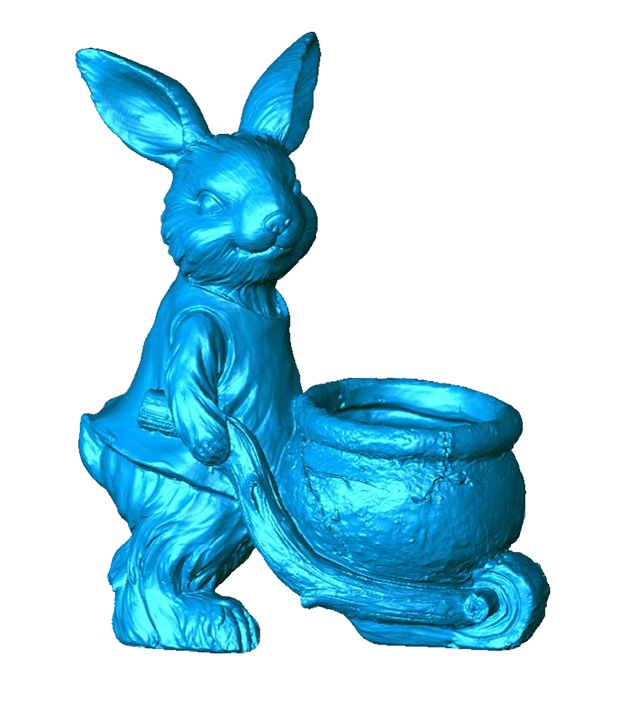

Dreambot White Light 3D Scanner can quickly scan various objects’ 3D model data even in strong light conditions with high precision, ranging between 0.05-0.1mm. The scanned data can be directly used for printing or mold making.

This product is designed to be portable and falls under the category of Handheld 3D White Light Scanners. It is widely used in various scenarios that require rapid and efficient acquisition of three-dimensional data. Whether in industrial manufacturing, cultural heritage preservation, medical fields, education, construction, or virtual reality, the handheld 3D white light scanner provides efficient and convenient 3D scanning solutions.

The Dreambot Handheld 3D White Light Scanner can completely transform your business processes, from enhancing product quality to streamlining workflows and reducing costs. Its versatility, ease of use, and ability to provide precise, high-resolution data make it an indispensable tool across various industries.

| Product model | 2F |

| Scan Type | Structured Light Scan |

| Scamning accuracy | Maximmum 0.05mm,0.05-0.1MMM |

| Vohune accuracy | 0.2-0.35mm/m(with reference ponit) |

| Scanning Speed | 500.000 points/s |

| Light source | 3 colour LEDS |

| Laser Class | Class Il (eye-safe) |

| Resolution | up to 0.05mm |

| Scanning format | 400x250mm |

| Stand off distance | 650 +-250mm |

| Space point distance | 0.03-3m |

| Weight | 800g |

| Printable data output | Yes, output file can used for 3D printer |

| Align mode | Feature Alignment, Hybrid Alignment, TextureAlignment, Global Markers, Safety Eye-safe. |

| data format | OBI,STL,ASC, PLY.P3 |

| Operating Temperature Range | 0-40 degree C |

| Special scan object | For transparent,reflective and dark object,please spraypowder first before scanning |

| System Supported | Wi10/11 64bit |

| Computer requirement | Graphics card:NVIDIA GTX770 or higher: VideoMemo1y: >4G;Processor:i7 or higher; Memory: 16G ormore; Port: high speed USB3.0 |

Qualities:

- High Precision: Ensures accurate and detailed 3D models with an accuracy range of 0.05–0.1mm.

- Quick Scanning: Able to swiftly acquire 3D information even in bright lighting.

- Portability: It is suitable for on-site scanning duties because it is lightweight and easy to carry.

- Adaptable Uses: Ideal for use in virtual reality, education, healthcare, industrial manufacturing, and cultural heritage preservation.

- Direct Data Utilization: Without additional processing, scanned data can be used straight away to create molds or for 3D printing.

- User-friendly: Easy to use interface and operation that requires little training.

- High Resolution: Produces high-resolution scans that capture the items’ minute details.

Advantages:

- Boosts Efficiency: Compared to conventional techniques, it takes a lot less time to collect 3D data.

- Improves Product Quality: Makes thorough inspection and quality control possible, guaranteeing that exacting criteria are fulfilled.

- Cost-effective: Reduces the need for physical prototypes and streamlines operations to cut production and development expenses.

- versatility: Provides a great deal of versatility to consumers by being able to be used in a variety of settings and applications.

- Creativity: Encourages creative applications in domains such as virtual reality and cultural conservation, offering fresh chances for expansion and advancement.

- Accessibility: Because it is easy to use and reasonably priced, powerful 3D scanning technology is now within the reach of small and medium-sized businesses.

- Decreased effort: Employees can concentrate on more strategic duties as a result of the scanning process requiring less manual effort.

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

More FDM 3D printers

3d Laser Scanner China

A 3D laser profile scanner measures the distance between the object and the scanner after projecting a laser beam onto an object’s surface.

Structured Light 3D Scanner

A wide range of industries and applications that demand precise and thorough 3D data about item geometry rely heavily on structured light 3D scanners.

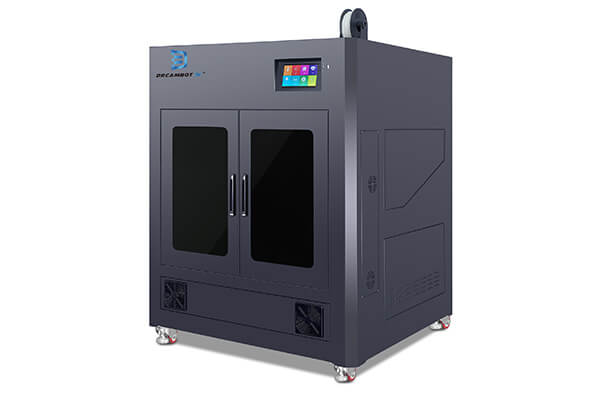

L-800 FDM 3D Printer

The L-800 FDM 3D printer is able to print larger objects sizes of up to 800x800x800mm. The model size is ideal for large commercial applications.

Contact Us

industrial 3d printer manufacturers

Dreambot 3D scanners assist you in scanning the structure of any object with high precision and accurate data.

3D scanners play a crucial role across various industries, helping businesses increase efficiency, reduce costs, and optimize products and services.

CE FCC ROSH approved

Solution for 3d printing

High quality

Dreambot White Light 3D Scanner Guide

What is a 3D Scanner

A 3D scanner is a tool used to build digital 3D models by capturing the physical form and look of real-world items. In order to create a three-dimensional representation of the object, it gathers spatial data points from the object’s surface and processes them. Numerous sectors make extensive use of this technology for tasks including reverse engineering, product creation, quality assurance, and digital preservation.

1.1, Structured Light Scanner

One kind of 3D scanning technology is called a structured light scanner, which projects structured light patterns onto an object to capture surface details and the object’s shape. This is the general procedure:

Projection: As an object is being scanned, the scanner projects a range of structured light patterns, like stripes or grids, onto it.

Reflection: Depending on the geometry and shape of the object, the light patterns are distorted when they interact with its surface.

Image Capture: Images of the distorted light patterns reflected from the surface of an object are captured by a camera or sensor.

Analysis: The 3D coordinates of the points on the object’s surface are found by using specialized software to analyze the taken pictures.

Point Cloud Generation: The software analyzes the data to produce a three-dimensional point cloud that depicts the surface geometry of the object.

Mesh Creation: After more processing, the point cloud data can be used to create a polygonal mesh, which shows the surface of the object as an arrangement of connected triangles.

Owing to their exceptional precision and accuracy, structured light scanners are well-suited for uses in reverse engineering, quality control, and digital preservation of cultural items. Industries like manufacturing, automotive, aerospace, and art restoration frequently employ them.

1.2, Blue Light 3D Scanner

Lighting: The item being scanned is illuminated by a focused blue light beam from the scanner.

Reflection: The blue light returns to the scanner’s sensors after interacting with the object’s surface.

Sensor Detection: The reflected blue light is detected by the scanner’s high-resolution cameras or sensors.

Data processing: To ascertain the form and surface characteristics of the object, specialized software analyzes the photos that were taken.

Point Cloud Generation: The program examines the information to produce a point cloud that depicts the object’s three-dimensional surface geometry.

Mesh Creation: A digital mesh model made up of connected polygons and vertices is usually created by processing the point cloud data further.

1.3, White Light 3D Scanner

Lighting: The object being scanned is illuminated with a diffuse white light pattern by the scanner.

Reflection: The white light interacts with the object’s surface and reflects back to the scanner’s sensors.

Sensor Detection: The reflected white light is detected by the scanner’s high-resolution cameras or sensors.

Data processing: To ascertain the form and surface characteristics of the object, specialized software analyzes the photos that were taken.

Point Cloud Generation: The program examines the information to produce a point cloud that depicts the object’s three-dimensional surface geometry.

Mesh Creation: A digital mesh model made up of connected polygons and vertices is usually created by processing the point cloud data further.

Application field of FDM 3D Printer

1.Accuracy and Precision

3D scanners offer incredibly precise measurements and comprehensive information on the actual sizes and shapes of objects. In fields where precise standards are required, such as manufacturing, healthcare, and engineering, this precision is essential.

2. Quickness and Effectiveness

3D scanners have the ability to quickly acquire extensive data in comparison to more conventional methods of measurement and documentation. This speed improves workflow efficiency and cuts down on the amount of time needed for processes like reverse engineering, quality control, and product design.

3. Inspection and Quality Control

In operations including quality assurance, 3D scanners are essential. By comparing the scanned models of products to their original CAD blueprints, they enable producers to minimize waste and faults by verifying that every item satisfies the necessary standards and specifications.

4. The process of reverse engineering

Reverse engineering requires the ability to recreate intricate 3D models of components or finished goods, which is made possible by these equipment. Redesigning parts, producing aftermarket components, or studying the designs of rival items can all benefit from this capacity.

5. Preservation of Digital Content

3D scanners are used by museums, cultural organizations, and research centers to digitally preserve objects, fossils, and historical places. By doing this, objects are studied and protected from physical handling, which over time may be harmful.

6. Use in Medicine

3D scanners are utilized in the medical field to collect precise anatomical data. This information is essential for designing sophisticated operations, dental appliances, and personalized prosthetics. The precision of 3D scanning technology enhances the efficacy of treatment and patient outcomes.

7. Individualization and Tailoring

Thanks to 3D scanning technology, products can be customized to meet unique needs. This is especially crucial in industries that require customized fitting, such orthopedics, dentistry, and custom manufacturing.

8. Improved Modeling and Construction

Using 3D scanners, engineers and designers can turn actual prototypes into digital models. Before beginning large-scale production, this integration expedites the design process and enables speedy revisions, simulations, and validations.

9. Media and Entertainment

3D scanners are used in the entertainment sector to produce lifelike digital models for motion pictures, video games, and virtual reality applications. The development of lifelike props, locations, and characters is made possible by this technology.

10. Building and Design

Building information modeling (BIM), site analysis, and renovation projects are among the uses of 3D scanning by architects and construction experts. Accurate site data is captured via scanners, facilitating more accurate project planning and execution.

11. Law enforcement and Forensics

3D scanners are used by law enforcement organizations to record physical evidence, accidents, and crime scenes. Investigations, reconstructions, and courtroom presentations are all aided by this thorough documentation.

2.1, Early Imaging Technologies

1. The art of photography

Early in the 1800s, photography was developed, making it one of the first methods of picture capture. In traditional photography, light is captured on a photosensitive surface—such as film or a digital sensor—by use of a camera. Although photography could depict objects and scenes in two dimensions, it was not able to offer the depth information required for precise measurement and analysis.

2. Imaging with X-rays

When X-ray imaging was developed in the late 1800s, it made it possible to see inside objects and living things. X-rays have the ability to pass through a variety of materials and expose internal details that are hidden from view. X-ray imaging has become essential for materials analysis and medical diagnosis.

3. The stereoscopy

In the 19th century, stereoscopy—also referred to as 3D photography—was invented. To mimic human binocular vision, two photos were taken at slightly different angles. These pictures appeared three-dimensional and had depth when seen through a stereoscope. Nevertheless, stereoscopy was not able to create detailed 3D models; it was only able to provide visual depth perception.

4. The use of photogrammetry

The early 20th century saw the development of photogrammetry, which is the process of snapping several pictures of a scene or item from various perspectives and then reassembling the three-dimensional coordinates using mathematical formulas. Archaeology, topographic mapping, and architecture have all benefited from this method of measuring and charting items and landscapes.

5. Computerized Tomography

The 1970s saw the introduction of computed tomography (CT) scanning, which completely changed medical imaging. X-rays are used by CT scanners to create cross-sectional pictures of objects or bodily parts. After that, a 3D model is created by digitally reconstructing these cross-sections. CT scanning became an essential diagnostic tool for medicine because it produced detailed interior images.

6. MRI

The late 20th century saw the development of magnetic resonance imaging (MRI), which creates detailed images of the body’s soft tissues using radio waves and magnetic fields. MRI scanners are commonly employed in medical diagnostics, particularly for brain and spinal cord imaging, and they generate high-resolution images.

7. Infrared Tomography

Modern 3D scanning was made possible by the development of laser scanning technology in the middle of the 20th century. In the past, laser scanners measured surfaces’ distances using laser beams and produced intricate 3D representations. Architectural documentation, industrial measurement, and surveying all made use of these scanners.

8. Methodical Light Scanning

An item is projected with a predefined pattern of light, and cameras are used to record the pattern’s deformation. This technique is known as “structured light scanning,” and it predates contemporary 3D scanners. The technology is able to recreate the object’s surface in three dimensions by examining the distortions. Compared to previous methods, this technology produced 3D models that were more detailed and accurate.

2.2, Imaging Technologies of 3D Scanners

Methodical Light Scanning

Using structured light scanning, an object is covered in a variety of patterns, most commonly stripes or grids. The deformation of these patterns brought about by the surface of the item is captured by a camera or sensor. The scanner reconstructs the object’s three-dimensional shape by examining the distortions.

Benefits

high resolution and precision.

quick speed of scanning.

Ideal for catching small details.

Uses:

industrial examination.

backward engineering.

preservation of cultural heritage.

2. Optical Scanning

A laser beam is used in laser scanning to determine how far an object is from its surface. Laser light is emitted by the scanner, and reflected light is detected by sensors. To compute the distance and create a 3D model, one can utilize either the phase shift of the reflected light or the time-of-flight of the light.

Benefits

high range and precision.

efficient in large-scale settings.

able to function under different lighting conditions.

Uses:

surveying architecture.

Environmental studies and forestry.

building and engineering.

3. The use of photogrammetry

Taking several pictures of an object from various perspectives is called photogrammetry. After that, software analyzes the photos to find places of overlap and use triangulation to rebuild the three-dimensional shape.

Benefits

economical when employing common cameras.

Excellent for big, intricate things.

able to record details in color and texture.

Uses:

Cultural legacy and archaeology.

Documentation related to real estate and property.

impacts in entertainment and the media.

4. Speak with Scanning

Contact scanning measures points by using a probe that makes physical contact with the object’s surface. In order to create a 3D representation, the scanner logs the coordinates of every point the probe touches.

Benefits

quite precise.

Ideal for materials with reflective or translucent surfaces that are difficult to scan.

doesn’t need particular lighting circumstances.

Uses:

manufacturing quality control.

precise technical design.

metrological and calibration.

5. Scanning with Computed Tomography (CT)

Through the use of X-rays, CT scanning produces cross-sectional images of objects that are merged to produce an intricate three-dimensional model. Scanning an object’s inside structure is a particularly valuable application of this technology.

Benefits

the capacity to examine interior characteristics.

high-quality pictures.

Ideal for dense and complicated materials.

Uses:

imaging in medicine.

industrial inspection (defects in castings, for example).

investigations in material science.

6. MRIs, or magnetic resonance imaging

MRI creates finely detailed images of soft tissues by using radio waves and magnetic fields. By scanning the object’s cross-sections and reconstructing them into a 3D model, it is able to gather 3D data.

Benefits

Safe and non-invasive for scanning living tissues.

photos with a high contrast for soft tissues.

absence of ionizing radiation exposure.

Uses:

diagnostics in medicine.

imaging of the brain and spinal cord.

biological sciences research.

7. Scanning with White and Blue Lights

Structured light scanning has several versions, such as blue light and white light scanning, which use different light wavelengths to record three-dimensional data. Because blue light scanners produce less noise from surrounding light, they usually offer superior accuracy.

Benefits

high level of detail and resolution.

decreased susceptibility to surrounding light.

useful for objects that are little to medium in size.

Uses:

exquisite arts and jewelry.

Inspection of small parts during manufacture.

uses in medicine and dentistry.

How Does a 3D Scanner Work

3D scanners are machines that scan actual items or surroundings to get information on their forms and, occasionally, their looks (such as color and texture). Digital 3D models are then created using this data. Depending on the kind of technology a 3D scanner uses, its essential operating principles can change. The general operating principles of the three most popular kinds of 3D scanners—photogrammetry, structured light, and laser—will be covered in this section.

1. Light Scanners with Structure

Using structured light scanners, an array of light patterns—typically stripes or grids—is projected onto the target. The deformation of these patterns brought about by the surface of the item is captured by a camera or sensor.

Projection: A predetermined light pattern is projected onto the object by the scanner.

Capture: The pattern’s deformation upon contact with the object’s surface is captured by the camera.

Analysis: To determine the distance between the object and the scanner at different times, software examines how the pattern has changed.

Model Building: A comprehensive three-dimensional model of the object’s surface is built using the distances.

2. Scanners using lasers

A laser beam is used by laser scanners to calculate an object’s distance from its surface.

Emission: A laser beam is directed at the object by the scanner.

Sensors pick up the reflected laser light by detection.

Calculating Distance: The distance can be determined using the phase shift of the reflected light or the time it takes for the laser to return (time-of-flight).

Model Construction: To produce a three-dimensional (3D) model, the scanner travels a laser across the object’s surface, gathering distance information at various locations.

3. Photogrammetry Taking numerous pictures of an object from various perspectives is called photogrammetry.

Photography: Several pictures are taken of the subject from different perspectives.

Software finds common points in the photos through feature detection.

Triangulation: To generate a 3D model, the positions are triangulated using the common points.

Model Construction: A comprehensive 3D model is created by the software by merging the triangulated points.

Important Parts of a 3D Scanner

Whatever the particular technology, the majority of 3D scanners have the following essential parts:

Light Source: The object’s illumination may come from a laser, an LED, or another type of light source.

To record reflected light or the distortion of projected patterns, use a camera or sensor.

Projector: A projector projects patterns onto an object in structured light scanners.

Software: Requires in order to calculate, analyze, and build the 3D model from the recorded data.

Procedure for 3D Scanning

Getting ready: The item to be scanned is positioned such that the scanner can get all of the required views.

When a structural light scanner or a laser scanner is used for scanning, light is projected or light patterns are deformed, and the reflected light is captured.

Data Capture: The scanner takes several pictures or reflections in order to gather surface data points from the object.

Data processing: The scanner’s software processes the collected data points to produce a three-dimensional point cloud.

Model Building: A digital three-dimensional model is built using the point cloud data.

Post-Processing: To ensure correctness and completeness, the 3D model may be smoothed, improved, or altered.

Uses for Three-D Scanners

Several industries make use of 3D scanners, including:

Manufacturing: For product design, reverse engineering, and quality assurance.

Healthcare: For the production of dental equipment, orthotics, and personalized prostheses.

Architecture: For historical preservation and building information modeling (BIM).

Entertainment: For the creation of digital content for virtual reality, video games, and film.

Archaeology: For precisely recording objects and locations.

Scanners Provided by Dreambot

4.1, Structured light scanner

Dreambot 3D Scanner with Structured Light

The Dreambot Structured Light 3D Scanner is an effective, high-precision scanning tool made to accommodate a range of industry requirements. The Dreambot 3D scanner generates detailed 3D models by swiftly and precisely capturing the 3D data of things through the use of sophisticated structured light technology.

Essential Elements Extremely Accurate Scanning

With the most recent advancements in structured light technology, the Dreambot Structured Light 3D Scanner can achieve scanning precision of 0.05mm to 0.1mm. This guarantees accurate recording of every detail, making it appropriate for applications that demand great accuracy.

Quick Capture

This scanner significantly improves job efficiency by scanning rapidly, especially in bright situations. Large objects or intricate buildings can be scanned quickly, allowing for the completion of high-quality 3D modeling.

Transportable Style

It is appropriate for a variety of on-site jobs due to its lightweight and portable construction. Because of its portable design, scanning jobs from various positions and angles can be effortlessly managed.

Broad Uses

Many industries, including industrial manufacturing, virtual reality, medical, education, and cultural heritage preservation, employ the Dreambot Structured Light 3D Scanner. It offers effective and practical solutions for product design, quality assurance, and digital cultural heritage preservation.

All Set for Use

The time from scanning to manufacturing can be greatly reduced by using the scanned data directly for 3D printing or mold creation without the need for additional processing procedures.

Use Cases

Industrial Manufacturing: Used in part development, quality control, and reverse engineering.

Cultural heritage preservation: aids in the digital preservation and restoration of items by museums and archaeologists.

Medical: Used to improve patient quality of life by producing personalized prosthetics and medical gadgets.

Education: Offers resources for high-precision 3D models for study and instruction.

Architecture: Applied to historical building preservation, construction monitoring, and architectural design.

Virtual reality: Offers realistic 3D model resources for the creation of video games and movies.

Enhancing Organizational Procedures

Businesses may optimize workflows, lower operating costs, and greatly improve product quality by utilizing the Dreambot Structured Light 3D Scanner. Because of its extreme precision and adaptability, it is a vital tool for all industries, revolutionizing workflows and fostering corporate expansion.

Select the Dreambot Structured Light 3D Scanner to increase the accuracy and efficiency of your job. Dreambot provides the best quality 3D scanning solutions, regardless of your industry.

4.2, White light scanner

White Light 3D Scanner Dreambot

The Dreambot White Light 3D Scanner is an effective, high-precision scanning tool made to accommodate a range of industry requirements. The Dreambot 3D scanner generates detailed 3D models by swiftly and precisely capturing the three-dimensional data of items using sophisticated white light technology.

Essential Elements Extremely Accurate Scanning

Using the most recent advancements in white light technology, the Dreambot White Light Scanner achieves scanning precision of 0.05 to 0.1 mm. This guarantees that every information is recorded precisely, making it appropriate for applications needing extreme precision.

Quick Capture

Even in bright conditions, the scanner can scan swiftly, greatly increasing productivity. Large objects or intricate buildings can be scanned quickly, resulting in high-quality 3D modeling.

Transportable Style

It is appropriate for a variety of on-site jobs due to its lightweight and portable construction. Because of its portable design, it is easier to perform duties like scanning from various locations and angles.

Broad Usage

The industrial manufacturing, medical, educational, construction, cultural heritage protection, and virtual reality areas all make extensive use of the Dreambot White Light Scanner. It offers practical and effective solutions for quality assurance, digital artifact preservation, and product design.

All Set for Instant Use

The time from scanning to production can be significantly decreased by using the scanned data directly for 3D printing or mold creation without the need for additional processing procedures.

Use Cases

Industrial Manufacturing: Used in part development, quality control, and reverse engineering.

Cultural Heritage Preservation: Helps archaeologists and museums preserve items digitally and restore them.

Medical: Contributes to the development of personalized prostheses and medical equipment, enhancing patients’ quality of life.

Education: Offers precise 3D models for instructional and investigative uses.

Construction: Used in historical building preservation, construction monitoring, and building design.

Virtual Reality: Provides lifelike 3D models for the creation of video games and movies.

Enhancing Organizational Procedures

Businesses may optimize workflows, lower operating costs, and greatly improve product quality with the Dreambot White Light Scanner. Because of its extreme precision and adaptability, it is a vital tool for a variety of industries, revolutionizing processes and fostering corporate expansion.

To increase the accuracy and efficiency of your work, go with the Dreambot White Light 3D Scanner. Dreambot provides the best 3D scanning solutions for your needs, regardless of your industry.

4.3, Laser scanner

Handheld 3D Laser Scanner Dreambot

Modern technology like the Dreambot Handheld 3D Laser Scanner is engineered to provide outstanding scanning results for a range of uses. With its user-friendly features and cutting-edge laser technology, this portable scanner is the perfect instrument for obtaining precise 3D data.

Important Elements

Excellent Accuracy and Precision

Impressively accurate, the Dreambot Handheld 3D Laser Scanner can capture details as precisely as 0.02mm. This guarantees a high level of detail in every scan, which makes it appropriate for applications requiring a high degree of accuracy.

Portability and User-Friendliness

This handheld scanner was made to be portable; it is lightweight and simple to use. Because of its ergonomic design, users may easily operate the device for extended periods of time, which makes it ideal for work involving on-site scanning.

Quick Scanning Rate

With its cutting-edge laser technology, the scanner can swiftly and accurately record three-dimensional (3D) data, which minimizes the amount of time needed to scan complicated surfaces or massive objects. This increases any project’s productivity and efficiency.

Adaptable Uses

Because of its adaptability and versatility, the Dreambot Handheld 3D Laser Scanner can be used in a variety of industries, including manufacturing, healthcare, construction, and the protection of cultural heritage. It offers trustworthy 3D data for a variety of uses.

Superior Quality Data Output

High-resolution 3D models produced by the scanner can be utilized for a variety of tasks, such as quality control, reverse engineering, and 3D printing. The thorough output guarantees that the scanned models adhere to industry requirements.

Software That’s Easy to Use

The Dreambot scanner comes with user-friendly software that makes data processing and model creation simple. With the help of the program, users can swiftly convert unusable scan data into 3D models. This streamlines the operation.

Use Cases

Industrial manufacturing: Helps manufacturers enhance product designs and optimize production processes. Perfect for reverse engineering, quality control, and fast prototyping.

Healthcare: Applied to the creation of personalized orthotics, prosthetic limbs, and other medical devices to guarantee optimal patient results and exact fit.

Construction and Architecture: Provides precise and comprehensive 3D models to support building design, construction verification, and documentation of historical structures.

Cultural Heritage Preservation: Assists in the repair and digital preservation of artifacts, guaranteeing the safekeeping of priceless cultural heritage for posterity.

Education and Research: Enhances the caliber of education and innovation by offering high-precision 3D models for scholarly and research uses.

Increasing Organizational Effectiveness

The goal of the Dreambot Handheld 3D Laser Scanner is to improve corporate productivity by providing quick, precise, and dependable 3D data. Because of its extreme precision and adaptability, it is a priceless instrument for enhancing product quality, optimizing processes, and cutting expenses in a variety of industries.

Conclusion

3D scanners have revolutionized various industries by offering unparalleled accuracy, efficiency, and versatility in capturing three-dimensional data. Structured light scanners, such as the Dreambot Structured Light 3D Scanner, provide exceptional precision and speed, making them ideal for applications in manufacturing, cultural heritage preservation, and medical fields. Similarly, white light scanners, like the Dreambot White Light 3D Scanner, excel in accuracy and quick capture, serving industries such as industrial manufacturing, construction, and virtual reality. Additionally, handheld laser scanners, such as the Dreambot Handheld 3D Laser Scanner, offer portability, ease of use, and superior data output, making them indispensable tools in fields like healthcare, education, and architectural design.

Overall, 3D scanners play a vital role in optimizing workflows, enhancing product quality, and reducing costs across various sectors. By leveraging the advanced capabilities of these scanners, businesses can stay competitive, innovate more effectively, and meet the demands of an ever-evolving market landscape. Whether it’s for reverse engineering, quality control, or digital preservation, investing in a high-quality 3D scanner like those offered by Dreambot can significantly improve organizational effectiveness and pave the way for future success.