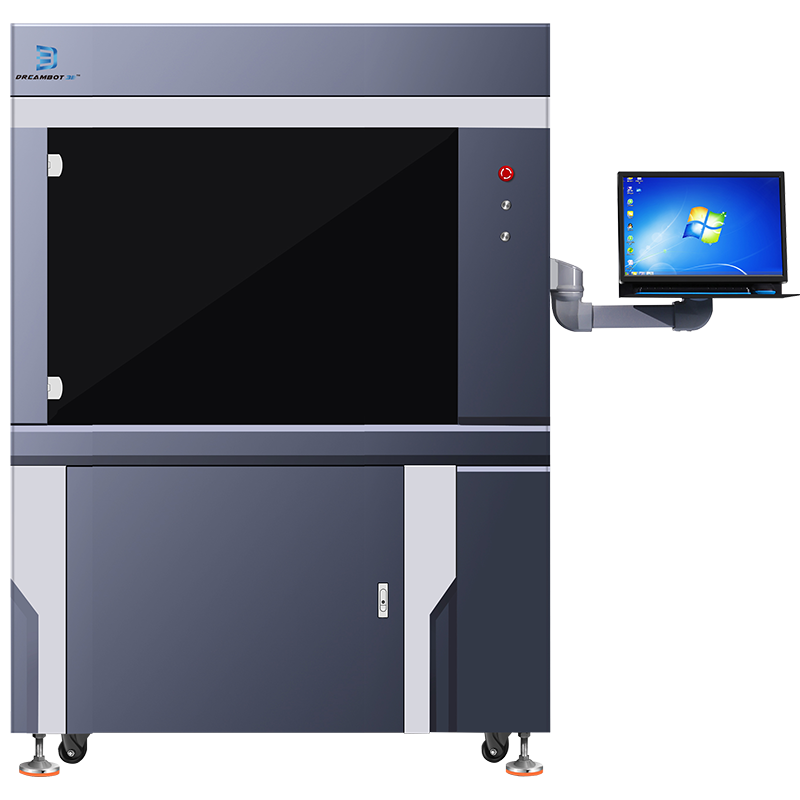

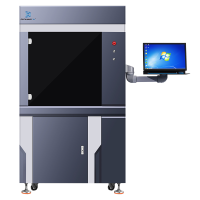

Stereolithography 3D Printer

SLA-1000 3D Printer

- Print size: 1000 (x) * 1000 (y) * 400 (z) mm

- SLA printers can work with a wide range of photopolymer resins, offering options for high strength, temperature resistance, and transparency.

- SLA printers are known for their ability to produce parts with fine details and smooth surface finishes, making them ideal for intricate designs.

Dreambot3D Stereolithography 3D Printer

Dreambot3D printer is an advanced manufacturing device that uses lasers to accurately solidify liquid resin layer by layer into solid objects.

The stereolithography 3D printer has a printing layer thickness accuracy of 0.1mm-0.15mm and excels at producing highly accurate and detailed parts.

Using a spot diameter of 0.1mm-0.12mm and a scanning speed of up to 12.0m/s, it ensures fast and efficient printing, making it an ideal choice for high-precision applications in the medical, dental, and jewelry industries. The printer’s ability to prototype complex geometries is also invaluable in the automotive and aerospace sectors.

| laser system | Laser type | Two-stage tube solid state laser |

| wavelength | 355nm | |

| power | 3000mw | |

| Maximum molding space (XYZ) | 1000*1000*400 | |

| Printing layer thickness accuracy (Quick production layer thickness) | 0.1mm-0.15mm | |

| Make tight layers thick | 0.05mm-0.1mm | |

| optical scanning system | Spot diameter | 0.1mm-0.12mm |

| Scanning speed | 5.0m/s (Standard) 12.0m/s(maximum speed) | |

| Scanning galvanometer | High speed galvanometer | |

| Recoating system | Intelligent vacuum adsorption coating system | |

| Accuracy of lifting system Vertical resolution | 0.0002mm | |

| Repeated positioning accuracy | ±0.01mm | |

| Resin cylinder capacity | 250/480/890 KG | |

| software environment | Operating system | WINDOWS7/10 |

| Control software | QUBEWARE PRO | |

| File format | STL & SLC | |

| Network compatibility | 10/100m Ethernet card access | |

| operating environment | Operating temperature range | 25-30℃ |

| Operating humidity range | No more than 40% | |

| Machine size (W*D*H) | 1250*1310*2100 | |

| Machine weight | 880KG(not including resin weight) | |

| Power supply | 200~240V AC 50/60HZ,16Amps | |

| Shelf life | 12 months |

Features:

High Precision and Accuracy: SLA printers offer a layer thickness accuracy of 0.1mm-0.15mm, and the capability to create tight layers as thin as 0.05mm. This precision is critical for applications requiring intricate details.

Fine Spot Size: With a laser spot diameter ranging from 0.1mm to 0.12mm, the SLA printer can produce finely detailed features, essential for complex designs.

Rapid Scanning Speed: The printer can achieve scanning speeds of 5.0m/s (standard) and up to 12.0m/s (maximum), ensuring quick and efficient printing processes.

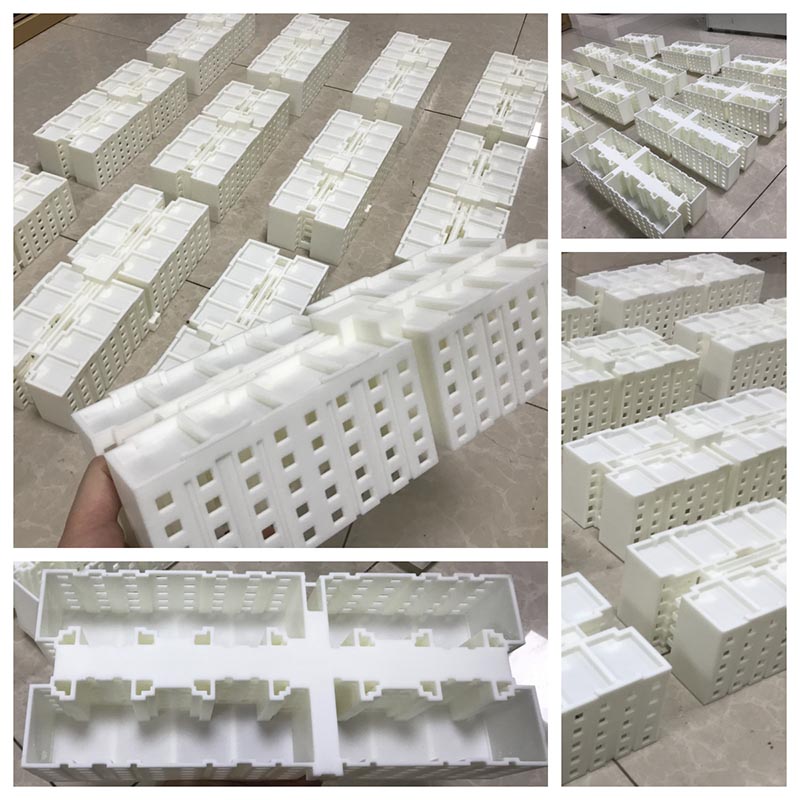

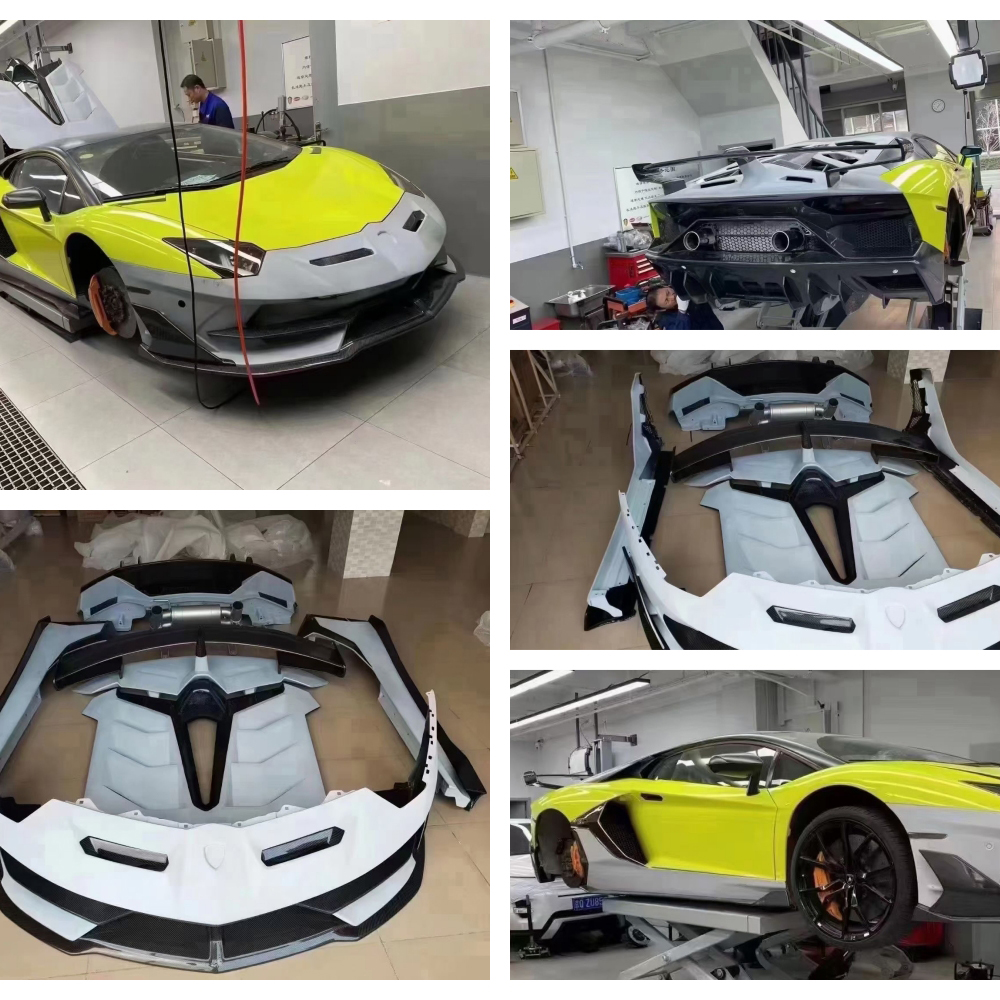

Complex Geometries: The technology supports the creation of complex shapes and structures that are difficult or impossible with traditional manufacturing methods.

Advantages:

Smooth Surface Finish: SLA 3D printers are known for producing parts with a smooth surface finish, reducing the need for post-processing and making them suitable for end-use applications.

Versatility in Material Compatibility: These printers can work with a variety of resins, allowing for a range of mechanical properties, such as high strength, flexibility, and temperature resistance.

Application in Precision-Demanding Industries: SLA technology is ideal for industries like medical, dental, and jewelry, where precision, detail, and surface quality are paramount.

Prototype to Production: Due to its accuracy and speed, SLA printing is beneficial not only for rapid prototyping but also for short-run production of parts, enabling faster time-to-market for new products.

Sealed Environment: The closed body of the SLA printer helps improve the success rate of prints by protecting the process from external contaminants, ensuring higher quality outcomes.

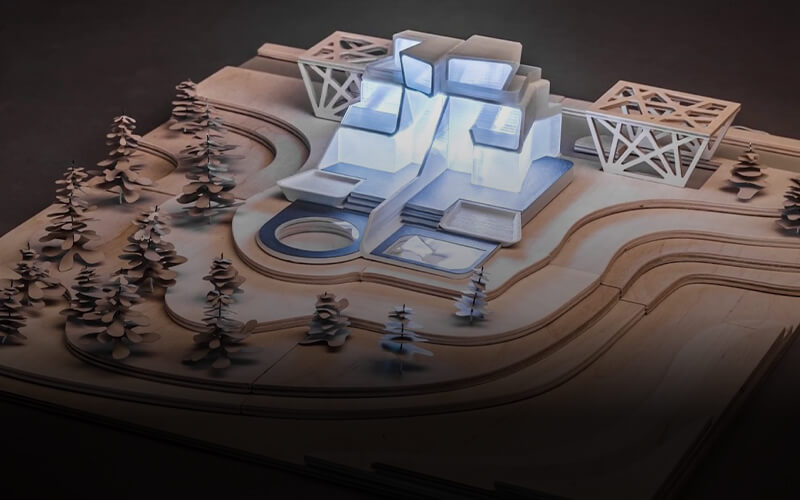

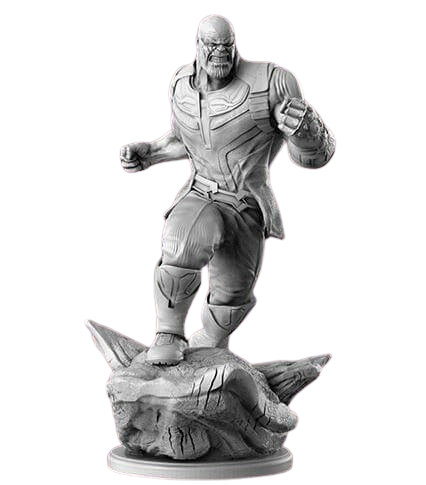

Application of Stereolithography 3D Printer

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

More SLA 3D printer

SLA 3D printing features fast forming speeds, with a comprehensive printing speed over 10 times faster than FDM, and it supports larger build sizes with high production efficiency.

SLA-800 3D Printer

The ME-192 is used for high precision printing for all sizes of printing. It adopts high definition pixels for printing.

SLA-300 3D Printer

This machine is also equipped with intelligent laser scanning technology, which increases printing efficiency by 40%, and it automatically adjusts the liquid level with a layer thickness accuracy of 0.02mm, improving the uniformity of the resin printing surface.

Dreambot3D Stereolithography 3D Printer FAQ

A stereolithography (SLA) 3D printer is a type of additive manufacturing technology that uses a laser to cure liquid resin into solid objects layer by layer. The process involves:

- Design: A 3D model is created using CAD software and sliced into thin layers.

- Printing: The model is printed by curing a photosensitive resin with a UV laser, building the object layer by layer.

- Post-Processing: After printing, the object may need additional UV curing for enhanced strength.

SLA printers are known for their high precision, detail, and smooth surface finishes, making them ideal for applications in jewelry, dental, and prototyping.

1. Technology

- PLA Printing: PLA is used in Fused Deposition Modeling (FDM) printers. In FDM printing, a filament of PLA is heated until it melts and is extruded through a nozzle to build up layers of the object.

- SLA Printing: SLA uses a laser to cure liquid resin into solid layers. The laser traces each layer of the 3D model on the surface of a vat of resin, solidifying it layer by layer.

2. Materials

- PLA: PLA is a thermoplastic filament that is fed into the printer in solid form and melts during the printing process. It’s biodegradable and made from renewable resources like corn starch.

- SLA: SLA uses liquid photopolymer resins that harden when exposed to UV light. There are various types of resins available, including standard, flexible, castable, and high-temperature resins.

3. Print Quality

- PLA: FDM/PLA prints tend to have visible layer lines and may not be as smooth or detailed as SLA prints. They are suitable for functional parts and prototypes but might require additional finishing for a smoother surface.

- SLA: SLA prints are known for their high resolution and smooth surface finish, making them ideal for detailed and intricate models. They can achieve finer details and smoother surfaces compared to PLA.

4. Accuracy and Detail

- PLA: FDM printers have a lower resolution compared to SLA printers. The accuracy depends on the nozzle size and printer calibration, but typically, FDM printers have larger layer heights and less fine detail.

- SLA: SLA printers offer higher precision and can produce parts with very fine details and intricate features. The laser’s high resolution allows for extremely accurate prints.

5. Print Speed

- PLA: FDM printing with PLA can be slower for complex models, as each layer is built up sequentially.

- SLA: SLA printing can be faster for certain types of models due to the continuous curing of layers, though the time for post-processing can add to the total print time.

6. Cost

- PLA: PLA filament is generally less expensive compared to SLA resins. FDM printers are typically more affordable as well.

- SLA: SLA resins can be more costly, and SLA printers tend to have a higher initial cost. However, the high detail and surface quality might justify the expense for certain applications.

7. Post-Processing

- PLA: PLA prints often require minimal post-processing, though they may need sanding or painting to improve surface finish.

- SLA: SLA prints usually require additional post-processing steps, such as washing and curing in a UV chamber, to achieve the final strength and appearance.

1. Technology

- SLS: Uses a laser to sinter powdered material (typically plastic or metal) into a solid structure. The laser fuses the particles together layer by layer, and the un-sintered powder supports the part during printing.

- SLA: Uses a laser to cure liquid resin into a solid form layer by layer. The resin is exposed to UV light, which hardens it according to the design.

2. Materials

- SLS: Can use a variety of powdered materials, including plastics like nylon, metals, and ceramics. This makes it versatile for different applications and functional parts.

- SLA: Primarily uses liquid photopolymer resins. There are various types of resins available, such as standard, flexible, castable, and high-temperature.

3. Print Quality and Detail

- SLS: Generally produces strong, durable parts with good mechanical properties. Surface finish may not be as smooth as SLA, but it’s suitable for functional prototypes and end-use parts.

- SLA: Known for high-resolution and smooth surface finishes. Ideal for detailed and intricate models, including prototypes and models where fine details are crucial.

4. Accuracy and Resolution

- SLS: Provides good accuracy and mechanical strength but might have slightly lower resolution compared to SLA. The layer lines can be more noticeable.

- SLA: Offers very high precision and resolution, with fine details and smoother surfaces. The laser’s high resolution allows for very accurate prints.

5. Build Volume

- SLS: Typically allows for larger build volumes, making it suitable for larger parts or multiple parts in a single print. The powder bed can support larger objects.

- SLA: Build volumes can be smaller compared to SLS, though there are larger SLA printers available. The support structures required for SLA prints can limit the size of the object.

6. Post-Processing

- SLS: Minimal post-processing is usually required for the printed parts, but cleaning and removing the un-sintered powder can be necessary.

- SLA: Often requires additional post-processing, such as washing in a solvent and curing under UV light to achieve the final strength and surface finish.

7. Cost

- SLS: Generally has higher equipment costs and can be more expensive for materials, but the cost per part can be lower, especially for functional prototypes and end-use parts.

- SLA: SLA printers and resins can also be expensive, but the overall cost depends on the size and complexity of the parts. SLA is often used for high-detail parts where the cost is justified by the quality.

8. Applications

- SLS: Suitable for producing functional prototypes, end-use parts, and complex geometries. Commonly used in industries such as aerospace, automotive, and medical.

- SLA: Ideal for creating detailed prototypes, jewelry, dental models, and other high-precision applications where surface finish is important.

Cost: SLA printers and resins can be expensive. The initial investment in the printer can be high, and the cost of resins, especially specialized ones, adds to the overall expense.

Post-Processing: SLA prints typically require additional post-processing. This includes washing the printed part in a solvent to remove excess resin and curing it in a UV chamber to achieve full strength and stability. This can add time and complexity to the workflow.

Material Limitations: While there are various resins available, they can be less versatile compared to the range of materials used in other technologies like FDM or SLS. The resins may have limited mechanical properties or be less durable for certain applications.

Resin Handling: Liquid resins used in SLA printing can be hazardous. They require careful handling, proper storage, and ventilation to avoid health risks. Spills and skin contact with uncured resin can be problematic.

Print Size: SLA printers generally have smaller build volumes compared to some other 3D printing technologies. This can limit the size of the parts you can print in one go or require more assembly of multiple printed pieces.

Surface Finish Issues: Although SLA produces smooth surfaces, the print can still exhibit layer lines, especially if the print orientation or settings are not optimized. Fine details are excellent, but overall surface imperfections might still be visible.

Print Speed: SLA printing can be slower than some other technologies, especially for larger or more complex models, due to the layer-by-layer curing process and the need for post-processing.

Environmental Impact: The use of photopolymer resins can have environmental implications, as they are not biodegradable and require proper disposal. The production and handling of resins also have environmental considerations.