Industrial SLA 3D Printer

SLA-300 3D Printer

- Print size: 300 (x) * 300 (y) * 400 (z) mm

- 355nm wavelength laser, high printing precision, strong resin compatibility, greatly improving printing efficiency.

- Automatic liquid level adjustment eliminates the fluctuation of liquid surface, and the paving thickness can be accurate to 0.02mm, which greatly improves the uniformity of resin printing surface

Dreambot3D Industrial SLA 3D Printer

Dreambot3D Industrial SLA 3D Printer utilizes a 355nm wavelength laser, offering high printing precision and strong resin compatibility, making it suitable for a wide range of industries, including prototype models, prototype production, and medical guide plates.

This machine is also equipped with intelligent laser scanning technology, which increases printing efficiency by 40%, and it automatically adjusts the liquid level with a layer thickness accuracy of 0.02mm, improving the uniformity of the resin printing surface.

The Industrial SLA 3D Printer offers modular upgrade options, supporting automatic double doors, automatic feeding, and remote monitoring, meeting the personalized customization needs of Industry 4.0.

| Printing Parameter | Laser | Diode Pumped Solid State | ||||||

| Max printing volume | 300*300*400mm | |||||||

| Forming Speed | 120g /h | |||||||

| Print layer thickness | 0.05-0.15mm adjustable | |||||||

| Accuracy | 100mm, ±0.1mm;L> 100mm, ±0.1%*L | |||||||

| Positioning accuracy | X Y axis ±0.001mm, Z axis ±0.002mm | |||||||

| Power | Resin Surface Powers 3W | |||||||

| Coating | Automatic vacuum adsorption coating | |||||||

| Laser scan speed | 6000nm /s | |||||||

| Recommended speed | 1200nm/s adjustable | |||||||

| Recommended layer thickness | 0.1mm adjustable | |||||||

| Beam point diameter | 0.12-0.6mm | |||||||

| Wavelength | 355nm | |||||||

| Resin tank | 50L (about 60kg) | |||||||

| Temperature Parameters | Workplace temperature | 20-28℃ | ||||||

| Workplace humidity | < 40%,non-condensing | |||||||

| Recommended Workplace | ≥3m*3m*2.8m | |||||||

| Software Parameters | Operating systems | CAD Solidworks 3Dmax UG Maya Rhino 3Done etc | ||||||

| 3D Modeling software | DB6.0 | |||||||

| Contorl software | SLC / STL | |||||||

| Input format | Ethernet | |||||||

| Internet | SD card,USB,WIFI | |||||||

| Physical Parameters | Printer dimensions | 850*930*1540mm | ||||||

| Package size | 900*990*1700mm | |||||||

| Gross weight | 230kg (not including resin) | |||||||

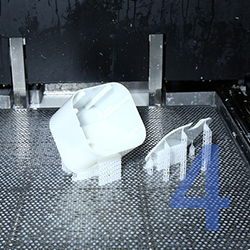

High precision printing

The printing accuracy is more than 40% higher than that of LCD light curing. The sinking forming method has smaller deformation than that of pull-up, more accurate size, saves assembly time, and meets the customization needs of large prototype samples in automobile, aerospace and other industries.Amazing printing speed

Independent research and development of intelligent laser scanning technology, high-speed scanning and vacuum adsorption scraper have improved the printing efficiency by 40%, and further improved the development efficiency of new products.Super stability

The z-axis, R-axis and scraper modules all adopt high-precision substrates to further ensure the long-term stable operation of the equipment, improve the printing stability, improve the material utilization rate and greatly reduce the model production cost.High degree of automation

Original control software, fully automatic setting of process parameters, optional three intelligent printing modes, simplified operation process, highly automated molding process, human-computer interaction experience and system security have been greatly improved.Personalized customization

We not only provide a variety of optional free customization, but also provide a number of modular upgrades, including automatic double door, automatic feeding, automatic environmental sensing, remote monitoring, etc., to meet the personalized customization needs of industry 4.0.

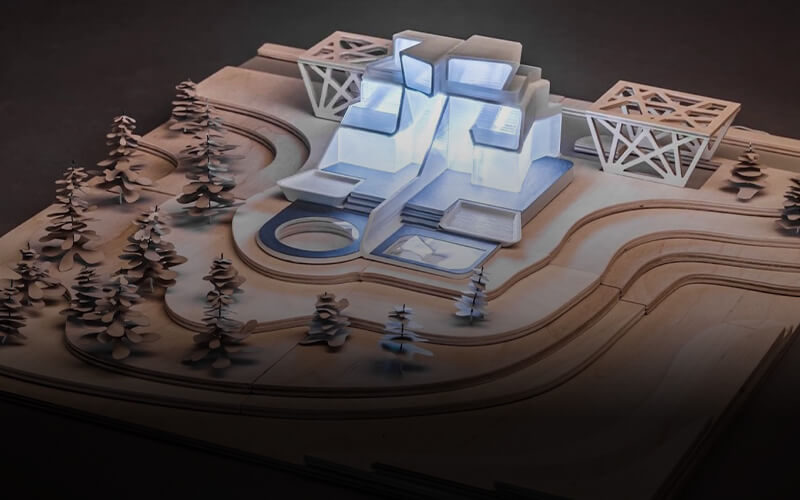

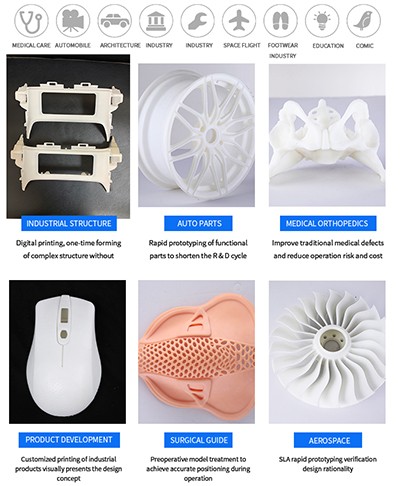

Application of Industrial SLA 3D Printer

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

With computer slicing software

The processing model and operation are more convenient and fast, the touch screen operation is more convenient, and the function is simple and easy to understand.

Greatly improve printing efficiency

The core control part of professional technology, 355nm wavelength laser, has high printing accuracy and many types of resin compatibility, which greatly improves the printing efficiency and greatly meets the high-efficiency requirements of enterprises for product development.

The liquid level is smoother

Automatic liquid level adjustment eliminates the fluctuation of liquid surface, and the paving thickness can be accurate to 0.02mm, which greatly improves the uniformity of resin printing surface

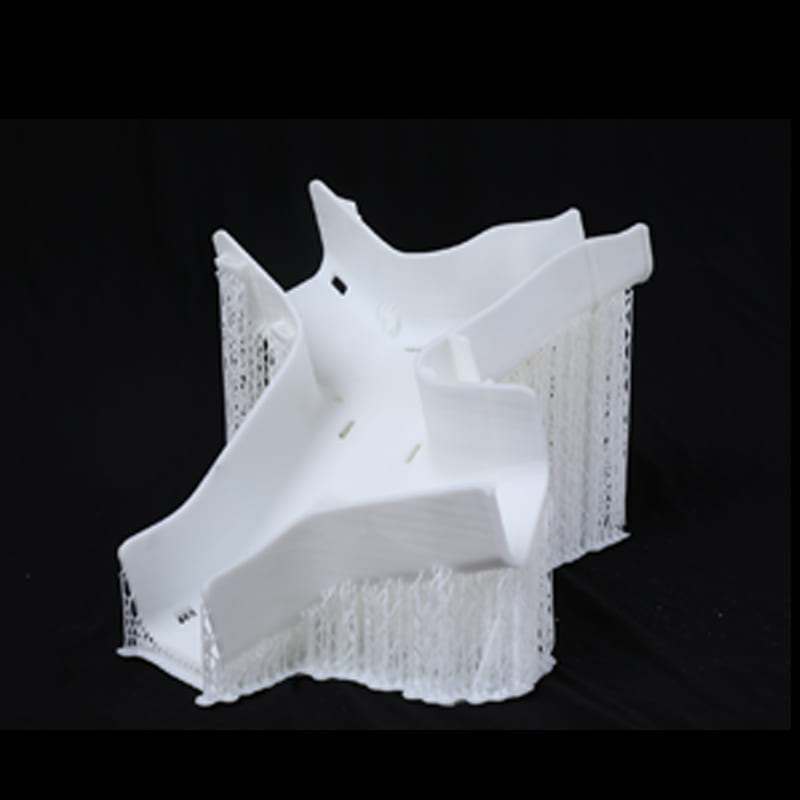

Easier support removal

With the new light touch support structure, the contact point between the model and the support is small and flat, which can be easily removed, and most of the surface is smooth without grinding

Meet the needs of different materials

Professional and technical core control device, with large space for adjusting printing parameters, which can meet the needs of printing with photosensitive resin in the market

More Industrial SLA 3D Printer

ME-192 LCD 3D Printer

The ME-192 3D printer provides a highly accurate 0.01-0.05mm layer of accuracy for you. It has a simple leveling that makes it suitable for new users.

DB-293 LCD 3D Printer

The DB-293 3D printer is used for printing high definition and professional 3D objects. It is best used for jewelry molds, building models, etc.

DB-550 LCD 3D Printer

The DB-550 3D printer is used to print complex objects with many angles. They are also used for large commercial printing.

Industrial SLA 3D Printer buying guide

一、Introduction to Industrial SLA 3D Printers

industrial SLA 3D printers offer unmatched precision, versatility, and efficiency, making them a vital asset for modern manufacturing and product development.

1.1, Overview of SLA Technology

SLA (Stereolithography Apparatus) is a 3D printing technology that uses a UV laser to cure liquid photopolymer resin into solid objects, layer by layer. Renowned for its high precision and smooth surface finishes, SLA is widely used in industries requiring detailed prototypes and intricate models. The technology allows for very fine layer resolutions, making it ideal for applications where accuracy is critical. SLA printers can work with various resins, offering versatility across different fields, including prototyping, medical devices, and consumer products. Recent advancements have enhanced its efficiency and broadened its industrial applications.

1.2, SLA 3D Printers Importance in Industry

The industry places great attention on SLA (Stereolithography) 3D printers because of its remarkable accuracy, adaptability, and productivity in creating high-quality components. For sectors that need precise and detailed models, these printers are essential since they allow for quick prototype and production with no need for post-processing.

SLA technology ensures that goods satisfy strict quality requirements by providing a clean surface finish and excellent resolution, which minimizes the need for lengthy human finishing. Complex geometries and elaborate patterns that are difficult to accomplish with conventional manufacturing techniques may be created because to this accuracy.

SLA 3D printers are also essential for cutting down on time-to-market since they provide rapid functional testing and design revisions. Their capacity to manufacture low-volume, customized components makes them perfect for sectors where small-batch manufacturing and customisation are crucial. The technology’s industrial usefulness is further enhanced by its ability to operate with a variety of materials, including those that possess particular mechanical qualities.

In conclusion, the efficiency with which SLA 3D printers can produce high-precision, high-quality items makes them essential to contemporary production processes. This is the reason for their significance in the business.

Key Features of Industrial SLA 3D Printers

Superior material variety, flawless surface finishes, and extreme accuracy set apart industrial SLA 3D printers. Their proficiency is in creating intricate and precise components with high build volumes and fine resolutions. Intelligent printing techniques, automated resin management, and modular upgrade possibilities are examples of advanced technologies that improve production efficiency and flexibility. Because of their long lifespan and dependability, these printers are essential to sectors that need constant, high-quality output.

2.1, Laser Technology

High Precision and Detail

- Accurate Manufacturing: Laser technology enables the creation of highly detailed and precise models, ideal for applications requiring intricate designs and fine features, such as jewelry, dental prosthetics, and complex prototypes.

Smooth Surface Finish

- Reduced Post-Processing: The laser’s ability to cure each layer of resin results in a smooth surface finish on printed parts, reducing the need for extensive post-processing, thus saving time and resources.

Material Versatility

- Wide Compatibility: SLA printers can work with various photopolymer resins that respond to different laser wavelengths, accommodating a range of material properties such as flexibility, rigidity, or high-temperature resistance.

Complex Geometries

- Advanced Design Capabilities: The precision of laser technology allows for the production of complex and intricate geometries that are challenging for other manufacturing methods, supporting innovative designs and advanced engineering applications.

Consistent Quality

- Uniform Curing: The laser ensures uniform curing of the resin, providing consistent quality across the entire build platform and maintaining high standards in production.

2.2, Used in the Medical Industry

1. Laser Technology

- High-Precision Laser: SLA printers use lasers with very fine and controllable focal points to cure each layer of resin accurately, ensuring the details and accuracy of the model.

- Laser Scanning System: Modern SLA printers often feature advanced laser scanning systems, such as galvanometer mirrors, which allow for rapid and precise scanning and curing of the resin, enhancing printing accuracy.

2. Layer Thickness Control

- Thin Layer Printing: SLA printers can print with very thin layers of resin (typically 0.025 mm to 0.1 mm). The precise control of layer thickness helps ensure that every detail of the print is accurately reproduced.

3. High-Resolution Display Screens

- High-Resolution LCD or DLP Screens: Some SLA printers use high-resolution LCD or DLP screens to control the curing area for each layer. The high-resolution displays provide finer light masks, further improving printing precision.

4. Precision Mechanical Structure

- Stable Print Platform: SLA printers feature precisely designed print platforms and bearing systems that ensure stability and accuracy of movement. This reduces mechanical errors and inconsistencies, enhancing overall printing accuracy.

- Precise Motion Control: The XY and Z-axis systems in SLA printers are often equipped with high-precision servo motors and guide rails to accurately control the position of the print head and platform, ensuring precision throughout the printing process.

5. Uniform Curing of Light

- Even Illumination: The laser uniformly cures the resin across the print area, preventing quality fluctuations caused by uneven light exposure. This uniformity helps ensure consistent quality throughout the entire model.

6. Advanced Software Algorithms

- Smart Slicing Software: SLA printers are often equipped with advanced slicing software that intelligently generates support structures and optimizes printing parameters, which improves precision and efficiency.

7. Environmental Control

- Temperature and Humidity Control: Some SLA printers feature precise environmental control systems, such as temperature-controlled chambers, to ensure stable conditions during printing. This helps prevent material expansion or contraction due to temperature changes, maintaining printing accuracy.

2.3, Material Compatibility

1. Variety of Photopolymer Resins:

- Standard Resins: SLA printers are compatible with various standard photopolymer resins suitable for general printing needs, providing good surface quality and precision.

- High-Strength Resins: Specially designed for durability, these resins are used to create parts that can withstand high loads or mechanical stress.

2. High-Temperature Resins:

- Heat-Resistant Resins: These resins are designed for applications that require high-temperature stability, such as heat-resistant tools or engine components, maintaining structural integrity under elevated temperatures.

3. Transparent Resins:

- Optical Transparency Resins: These resins offer excellent optical clarity, suitable for applications requiring high transparency, such as optical components, clear housings, or display models.

4. Biocompatible Resins:

- Medical Resins: Designed for medical applications, these resins ensure safety and compatibility with biological tissues, making them ideal for medical models, prosthetics, and dental devices.

5. High-Resolution Resins:

- Detail-Oriented Resins: Providing extremely high resolution and detail, these resins are used for complex models and fine craftsmanship, such as jewelry making or prototype design.

6. Engineering Resins:

- Engineering Resins: Known for their excellent mechanical properties and durability, these resins are used for functional parts and engineering test pieces.

7. Custom Resins:

- Specialized Custom Resins: Some SLA printers can use custom-formulated resins to meet specific industrial needs or customer requirements, offering greater flexibility and adaptability.

Why do we need SLA 3D Printers?

1. Excellent Accuracy:

Exceptional Precision and Detail The potential of SLA 3D printers to create very precise and detailed prints is well known. Fine resolutions and complex patterns are made possible by the use of lasers and photopolymer resins, which are crucial in fields like high-detail modeling, jewelry creation, and prototyping.

2. Exceptional Surface Quality:

Even Surfaces SLA technology produces a clean surface finish with less need for post-processing because of its layer-by-layer curing method. This is especially helpful for high-end prototypes and dental models, two areas where surface quality is very important.

3. Complex Geometry:

Superior Design Skills Complex geometries and minute details are difficult to accomplish with conventional 3D printing methods, but SLA printers can produce them. They are perfect for creating elaborate models, sophisticated prototypes, and finely detailed creative creations because of their capabilities.

4. Material Versatility:

Broad Range of Resins: Standard, high-strength, transparent, high-temperature, and biocompatible photopolymer resins are among the many types of photopolymer resins that SLA technology enables. Because of its adaptability, SLA printers may be used for a wide range of applications and material requirements.

5. Fast Prototyping:

Accelerated Development: SLA 3D printers provide fast prototyping by manufacturing high-caliber models for validation and testing in a short amount of time. This quickens the cycle of product development, enabling quicker design iterations and refinements.

6. Detailed Outputs with High Resolution Printing:

Because SLA printers can produce high resolutions, they are a good fit for applications that need precise details and precision, such intricate figurines and industrial components.

7. Steadiness and Dependability:

Repeatable Outcomes: Repeatable and consistent results are produced by SLA 3D printers, guaranteeing that high quality and accuracy are maintained over several prints of the same design. For settings involved in production and manufacturing, this dependability is essential.

8. Few Support Structures:

Effective Printing: SLA technology often reduces material waste and post-processing efforts by requiring fewer support structures than traditional printing techniques.

9. Particularized and Tailored Uses:

Customized Resolutions: specialist applications, such medical devices, personalized prostheses, and specialist engineering components, are made possible by the ability to employ specially designed resins and modify printing conditions.

10. Economical for Superior Results:

Economical Production: SLA printers may be economical in the long term despite the initial expenditure because of their capacity to provide excellent outputs with little need for further finishing or post-processing.

SLA 3D printers are vital equipment for a variety of sectors because of their exceptional accuracy, adaptability, and capacity to quickly generate intricate and detailed prints. Their sophisticated qualities render them advantageous for uses in anything from product development and prototyping to specialized manufacturing and creative pursuits.

Applications of Industrial SLA 3D Printers

1. Rapid Prototyping:

- Product Development: SLA 3D printers accelerate the prototyping process by producing high-quality, detailed models quickly. This allows designers and engineers to test and iterate their designs faster, reducing time-to-market for new products.

2. Medical Devices and Prosthetics:

- Custom Medical Solutions: SLA printers create custom prosthetics, dental implants, and surgical guides with high accuracy and biocompatibility. They are used to produce detailed anatomical models for pre-surgical planning and training.

3. Jewelry Design:

- Detailed Models: In jewelry manufacturing, SLA printers produce intricate and detailed patterns for casting. They enable designers to create complex designs and fine details that are difficult to achieve with traditional methods.

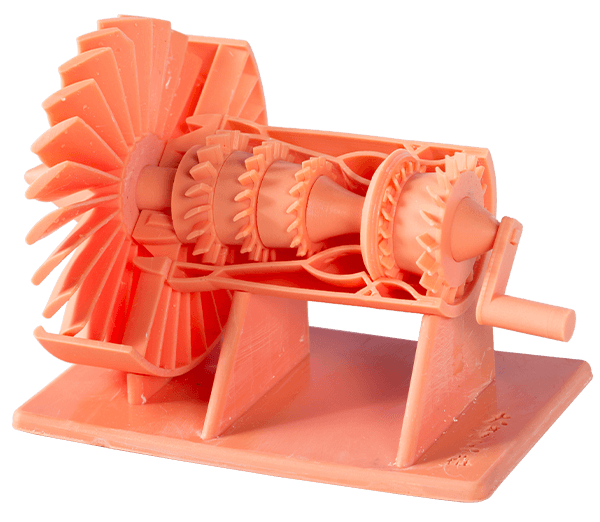

4. Engineering and Functional Parts:

- High-Performance Components: SLA technology is used to produce functional parts with high mechanical properties. These parts can be used in testing, assembly, and final production, providing accurate representations of the final product.

5. Aerospace and Automotive:

- Complex Parts: In aerospace and automotive industries, SLA printers create lightweight, high-strength components and prototypes. They are used for developing intricate parts, tooling, and models for both design and functional testing.

6. Consumer Goods:

- Product Customization: SLA 3D printers are used to create custom consumer goods, including personalized items and bespoke designs. They offer a way to produce unique, high-quality products tailored to individual customer preferences.

7. Architecture and Construction:

- Detailed Models: Architects and construction professionals use SLA printers to produce detailed scale models of buildings and structures. These models help visualize and communicate design concepts effectively.

8. Art and Entertainment:

- Creative Works: In the art and entertainment industries, SLA printers are used to create detailed figurines, prototypes for movie props, and intricate art pieces. The high resolution and precision allow for the reproduction of complex and detailed designs.

9. Research and Development:

- Experimental Models: SLA printers support research and development activities by enabling the creation of experimental models and prototypes. They facilitate the testing of new concepts and materials in a cost-effective manner.

10. Tooling and Molds:

- Production Aids: SLA technology is used to create tooling and molds for various manufacturing processes. The precision of SLA prints ensures that molds and tools are accurate and functional, improving the efficiency of production operations.

11. Educational Purposes:

- Teaching and Training: SLA 3D printers are utilized in educational settings to teach students about design, engineering, and manufacturing processes. They provide hands-on experience with advanced manufacturing technologies.

Conclusion

Industrial SLA 3D printers are very precise, adaptable, and capable of handling intricate geometries, making them formidable instruments in a variety of industries. Their uses range from precise jewelry designs and useful technical components to quick prototyping and personalized medicinal treatments. SLA technology makes it possible to produce precise models fast and effectively, which speeds up the process of developing new products and improves the capabilities of sectors including consumer goods, architecture, automotive, aerospace, and consumer goods.

SLA 3D printers are invaluable in a variety of industries due to their benefits, which include excellent resolution, compatibility with diverse materials, and the capacity to create complicated designs. SLA printers are a useful tool for precise and effective production, whether they are used to create intricate artwork, bespoke consumer goods, or practical components. Their significance in contemporary industrial and creative processes is highlighted by their influence on innovation, efficiency, and personalization.