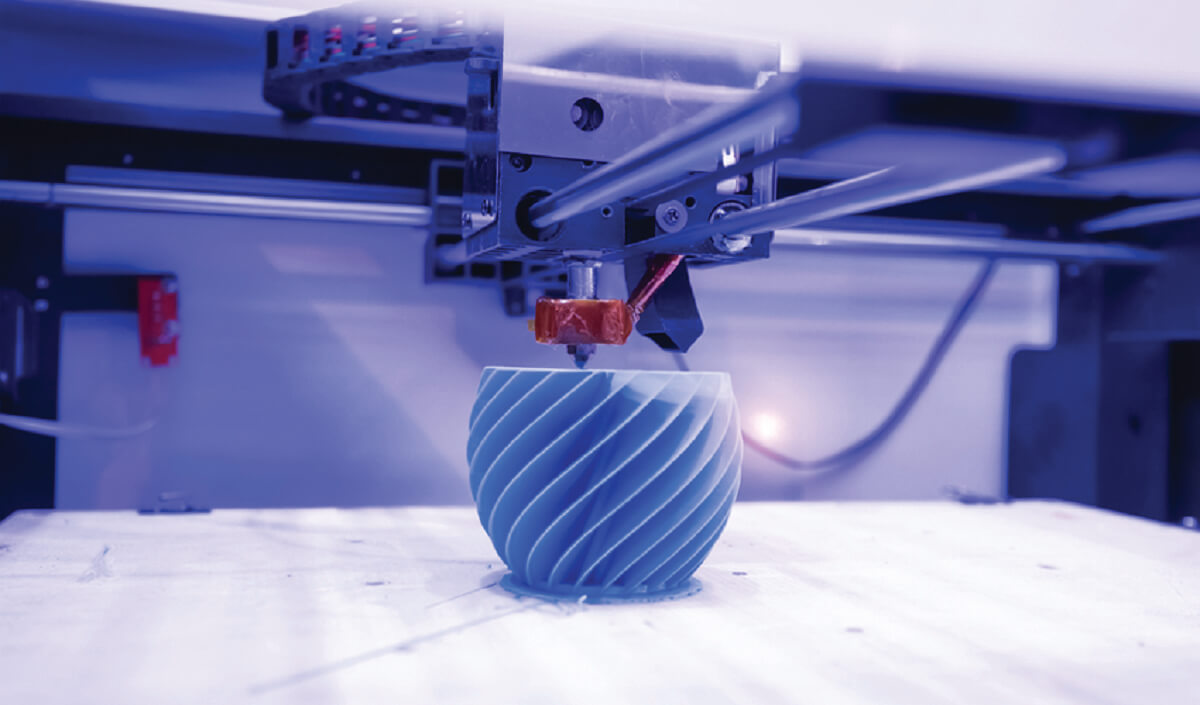

Gun 3D Printer

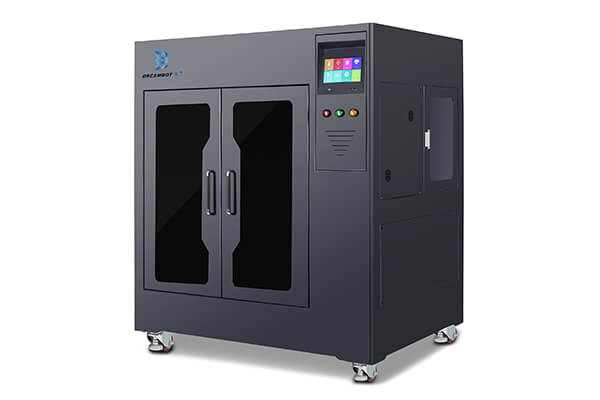

The gun 3D printer allows you to create gun prototypes of different sizes and designs. The gun 3D printer is used in the firearm, military and defense industries. Gun 3D printer price is affordable.

How 3D printers work for gun

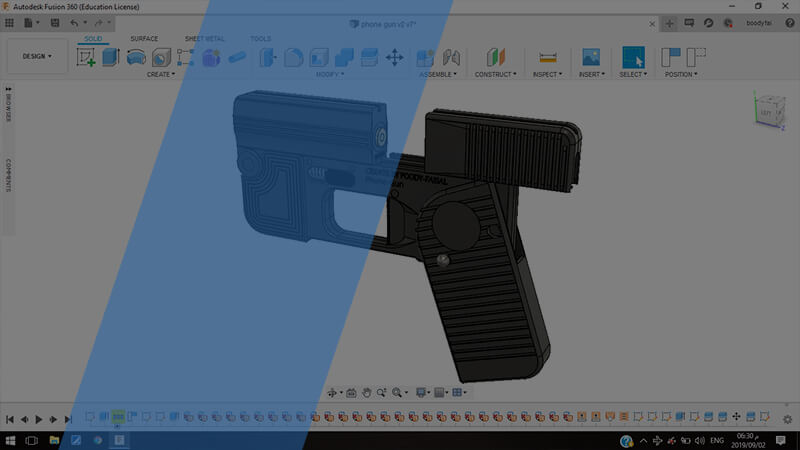

3D design

gun

3D printing

gun

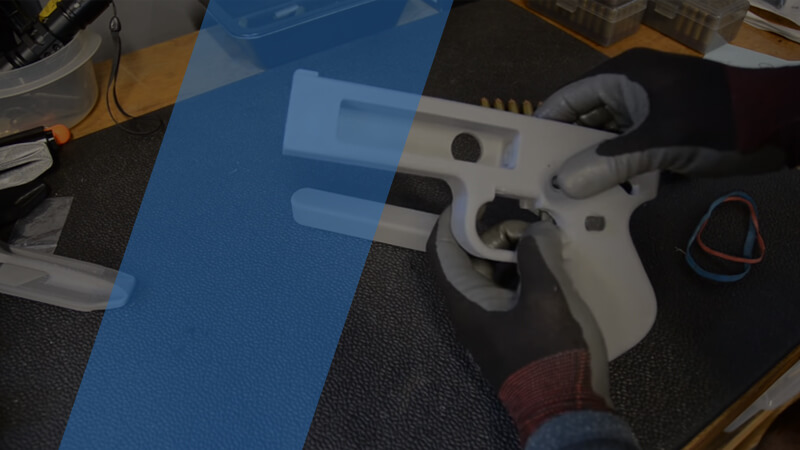

assemble

gun

3D printed guns are a way for legitimate gun manufacturers to exceed traditional design limitations. It is possible for you to print a plastic gun frame and use metal in the action and barrel.

The gun 3D printer has a high printing definition that makes it adoptable in the military.

The printing speed is about 20mm/h, therefore completing your printing operations faster even for multiple printing.

You can print continuous gun models for many hours without affecting the printing quality of the printer.

The toy making industry makes 3D printed toy guns made with 100 percent plastic for children’s toys. Large batches of 3D printed toy guns can be printed with the gun 3D printer.

The gun 3D printer is highly efficient for printing, no leveling of the printing bed is required.

The LCD display is easy to navigate and you can switch between Chinese and English.

guns 3D printers for your Choice

Don't know how to choose a model?

Are you confused about how to choose the correct model and type of 3d printer? We support 24/7.

4 points why choose us

Automatic resume printing

Continue to print the unfinished model after the power is restored when the power fails

PLC control system

All 3d printers are equipped with PLC control system as standard, makes the operation more convenient, and reduces the error.

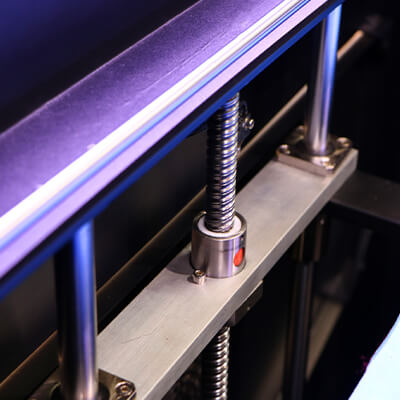

Extremely speed printing

Higher straightness, lower friction coefficient, better smoothness, higher positioning accuracy and more stability during printing.

Reinforced structure

The all-metal one-piece shell reduces resonance, makes printing more stable and improves printing accuracy.

What our customers say

How 3D printers are used in the gun and gun model making

gun 3D printer buying guide

1.1, Exploring the history of 3D printed gun parts

1.2, Are 3D printed guns worth paying attention to?

1.3, What countries think about printing guns – The legal minefield of 3D printed guns

A few years back, 3D printing models or objects seemed to be a very sci-fi fantasy thing that was only reserved for high-end and well-known prototyping labs. Now, things have changed a lot.

Nowadays, regular printing objects in the home is gradually becoming a reality. Besides, the 3D printing technology also has brought more affordability and performance to the consumers.

After the 1990s, the technology of 3D printing started to evolve and picked up a decent speed. It has now reached a stage where all can use these fantastic machines to create 3D models.

With the participation of different companies and experts, the development of 3D printers quickly evolved to a point where the global market presents a vast selection of machines to the buyer.

3D printing technology is gradually creating a robust place in different industries, such as automotive, aerospace, education, health, dental, and more. However, another industry uses these machines quite widely, and that industry is a firearm or gun-making company.

3D printing, also known as additive manufacturing, helps firearm companies drive innovation forward with lower lead times and lower costs for the prototypes.

You will mainly find two types of 3D printers in the market, i.e., LCD and FDM 3D printers. But in the firearm industry or for gun production, FDM printers are used. Because only an FDM 3D printer can produce durable parts or models to create guns.

Besides, 3D printers create parts with a maximum precision level compared to gun parts and models using traditional equipment. Besides, the tensile strength limit of 3d printed plastic gun is also good. Furthermore, the 3d printer gun model will be resistant to chemicals and water.

With time, 3D printed working gun models appear more and more, and lawmakers and makers have noticed this. There has been an excellent level of efforts to stifle the use and production of 3D printed firearms.

Manufacturers are now putting a lot of effort into making them more accessible, easier to the manufacturer, and cheaper.

However, to get the best result in this, you need to buy the best gun 3d printer, and this is where most of the 3D printer buyers face challenges. This guide will greatly help you understand how to choose the best 3D printer for gun manufacturing if you are one of them. Besides, we will also discuss the legality of 3d printed gun stock and its history. So, let’s talk about this in detail.

The current situation of 3D printed guns

It is a fact that the utilization of 3D printing, or you can say additive manufacturing, has brought a whole new element to firearms technology. This technology has open new and faster production and development process for firearm manufacturers across the globe. On the other hand, for criminals, activities, hobbyists, an affordable gun 3d printer offer potentially unregulated access to different types of firearms.

Craft-made weapons have a year-long history of nefarious activities and have some characteristics perfect for various criminal activities. These types are firearms that are entirely unregistered and are disposable and easy to manufacture.

The 3D printed firearms or a 3d printed functional gun have added a modern twist to firearms’ traditional production. With easy access to a computer, advanced FDM 3D printer, and quality 3D printing materials, a perfect weapon can now be produced relatively quickly.

The new firearm technology remained static for a new century with self-contained pressure bearing surfaces, metallic cartridges, and looking methods. In this segment, the most basic form is a “Slam-fire” shotgun that can come with a tube and a perfectly designed striker to trigger the cartridge.

You will mainly find two types of 3D-printed firearms in this industry, manufactured entirely using high-quality printed polymer and other materials. Another one is hybrids that combine 3D printed parts with the traditionally manufactured components. A perfect example of the hybrids can be the 3D printing of pistol frames and producing non-pressure bearing lower receiver parts using polymers.

However, regardless of where you are standing now, the rise in the power and status of 3D printed weapons poses some difficult questions. To know more, let’s have a look at the recent happenings related to fully 3d printed guns.

Online 3D printed gun banned on 11-14-2019

As per the report, a federal judge in Seattle, USA, ruled that Defense Distributed, the well-known open-source hardware organization, is not permitted to publish the blueprints of 3D printable guns on the internet.

Stating they were violating the laws of arms export as the blueprints can be easily accessed and used by people across the globe. However, Robert Lasnik, a federal judge, termed this illegal.

States suing the U.S. over the 3D printed gun laws

A combination of around 20 states and the District of Columbia is now opposing the United States of America’s federal government over a plan made by the Trump Administration to enable people to share and use 3d printed gun models or gun blueprints online. However, critics are very concerned about publishing the 3D gun’s blueprints online as it can offer easy criminal access to the guns that can be traced.

However, it may be noted that legal firearm manufacturers can use a gun 3d printer that utilizes FDM printing technology. And most of the gun manufacturers are using it.

3D printing technology- Allowing firearm manufacturers to be economical and flexible

With the best FDM 3D printer, you can now easily print different parts for firearms in small batches, enjoying a lower manufacturing cost than traditional methods. This printing technology can be leveraged to produce intricate or complex pieces like backplate covers, trigger systems, hammers, recoil spring plugs, and more precision.

On the other hand, 3D printing’s rapid prototyping feature has allowed firearms manufacturers to reduce product development’s lead time. On the other hand, 3D printed parts also help lower the possible risk of trial-and-error methods as the prototypes are most cost-effective.

Besides, product revisions can be made quite easily and printed with the required adjustment. Whether you are making custom parts for the production of creating a prototype for a brand-new design, 3D printing can be a perfect solution for you. Now., let’s talk about the history of 3D-printed guns and their parts.

1.1, Exploring the history of 3D printed gun parts

How did the story of the 3D printed gun start? Keep reading to know all the things. It all started in 2012 when Cody Wilson introduced his idea to convert the fire-arm design into open-source files, letting the public print a weapon at their home.

Speaking about Cody Wilson, he is a self-proclaimed crypto expert, and he has completed his Law degree from the University of Texas. He was neither a deranged geek nor a criminal. After a year of studying there, he left the university to develop and distribute functional 3D-printed guns.

He also established a company called Defense Distributed for this purpose.

In 2013, the first Computer-Aided Design gun model file arrived online, which can be downloaded without paying money. The digital design file went viral immediately, and in just two days, it witnessed more than 100,000 downloads. However, after a few days, Defense Distributed removes the gun design file from the site.

As per the data, Defense Distributed has also created an AR-15 type rifle lower receiver, and the design is 3D printable. The gun is capable of lasting for 650 rounds, and it also supports different types of magazines.

However, the company faced various legal cases for violating the Arms Export Control Act.

In 2015, Wilson sued the US government, and in 2018 the case was settled by the Department of Justice, stating Wilson’s right to release the instructions online for the production of 3D printable firearms.

The incident has inspired the development of multiple decentralized 3D-printed gun communities, including FOSSCAD and Deterrence Dispensed.

In the year 2013, Solid Concepts, a Texas-based company, showcased the M1911 pistol’s 3D printed version made of metal, with the help of an industrial 3D printer. Oceania Defense, a New Zealand-based company, produced 3D printed suppressors made of titanium, and they are around 50 percent lighter than the traditional ones.

A list of 3D printed weapons and parts

- Raptor Grip M500

It was made public on 15th December 2011. Shockwave Technologies produced it using the FDM printing method. Some important facts of this product are; the grip’s prototypes were 3D printed and then tested through firing. In a glass-filled polymer, grips were injection molded.

As per the report, the 3D-printed grip M500 can survive 200 rounds of 00 buckshot and 400 rounds of 8 birdshot. It never fails to work. On 27th December 2011, the Raptor Grip M500’s production version went on sale.

- The Cuomo Mag

It was introduced in January 2013 by Defense Distributed. This magazine can hold 30 rounds. As per the report, the first prototype was made with Connex26 using a transparent material called VeroClear. During the taste, it was able to handle less than 342 rounds.

- Feinstein AK Mag

Defense Distributed revealed this in March 2013. The company made this using Stratasys Dimension SST 3-D printer that utilizes FDM printing technology. It was a 30-round magazine for AK-47.

- Red Rocket Shotgun Slug

Jeff Hessel introduced this in May 2013, and they made it with the help of FDM and ABS using Solidoodle 3D printer. The printer managed to produce the bullet within an hour, and when tested, the bullet easily pierced through a 2×12 piece of pine wood.

- 3DX Muzzle Brake

Introduced by Sintercore, it was made through DMLS. The brake utilizes metal Inconel material. During the test, the part managed to fire around 7900 rounds on semi-auto mode. On full auto mode, it fired ten magazines. It may be noted that USSOCOM- US Special Operation Command’s Science and Technology Directorate invited Sintercore to demonstrate the part for use by the elite troops. The test was conducted on 5th August 2014.

- FGC -9

Introduced on 27th March 2020, this Parabellum Pistol caliber carbine was made by JStark1809 using FDM technology. The weapon is based on Shuty AP-9, and the barrel can be rifled through ECM- Electrochemical machining.

- Chimera 410

This is a hybrid firearm. Pilotgeek combines FDM and PLA to produce this single shot shotgun. The gun utilizes a steel pipe as a barrel and, for its frame, a rectangular steel tube. It has 3D printed parts for fire control components, receivers, and more. There are 3D printed jigs that offer a guide for accurate drilling and cutting of components.

1.2, Are 3D printed guns worth paying attention to?

The first case of 3d print real gun came to the limelight when Cody Wilson, a college student from Texas, introduced 3D gun design and created a functional weapon using an FDM 3D printer. The weapon can easily slip by the metal detectors as it is made of resins.

If you search online for 3d printed automatic gun, you will find much information with videos. If every person starts producing a 3D gun, then a time will come when everyone has a gun, and the situation can be terrifying.

The technology behind 3D printing has advanced dramatically, and current types of 3D printers can produce more sophisticated devices, like guns or other firearms.

That is why Congressman Israel is now proposing the Undetectable Firearms Modernization Act. If it gets a green signal, this can prevent guns’ illegal manufacture, and only registered companies are created guns.

The weapons are 3D printed in different pieces, and then the users can assemble them to get a functional 3d printed plastic gun. The only metal parts that the gun will have the bullet and the firing pin.

Some firearms can easily evade metal detectors, with a small steel and firing piece, complying with the Undetectable Firearms Act. Every gun can be reused and can fire multiple rounds based on the types of parts.

3D-printed guns may fire hundreds of rounds, but are they durable?

The right answer is no, they are not durable like the traditional guns, and some shooting ranges ban the 3D firearms from being used.

As per a report, The Liberator, a 3D printed gun made by Defense Distributed, broke down after a single discharge. Experts have said that some guns can be created using a gun 3d printer, but they are not reliable and don’t have the commercial qualities like a real gun.

3D guns produced by plastic ABS-M30, the material used to make toys, can fire one .380-Caliber round for around eight times. When fired, the bullet traveled around 11 inches into gelatin. Compared to the original .380 pistol, the bullet can travel around 18-inches.

However, the demand for 3d printed toy gun is getting higher. There are some toy 3D guns that kids love to have, and they are the exact replicas of guns used by superheroes. For example, using an FDM 3D printer, you can create a batman grapple gun.

Look at the image, and you will find it a fully functional toy gun along with a hook-projectile. When you fire up the gun, the projectile will come out of the weapon, and it will automatically release its hooks. Using the cord, the projectile is connected to the bat gun. There is a round chamber using which you can roll back the cord inside. To give it a realistic look, the gun has a 9v battery and LED lighting system.

If you are a toy manufacturer and want to produce some cool toy guns to expand your business, then an FDM 3D gun printer will be the best choice for you. However, you should not use it for any illegal activities. As long as you are following the law, you can keep using a gun 3d printer.

1.3, What countries think about printing guns – The legal minefield of 3D printed guns

3D printed gun is generally printed in different plastic parts, and the users have to assemble by themselves. As per the experts, like Wilson, one can create a pistol within 24 hours. Even though there are DIY kits for manufacturing guns at-home, blueprints of 3d printable gun parts will allow the users with an FDM 3D printer easier access.

However, some gun experts have said that criminals are unlikely to utilize the blueprint as 3D printers required to print guns are quite expensive. On the other hand, guns can deteriorate relatively faster than traditional weapons. Printers required to make the guns can cost around USD 2000 to USD 20,000.

You may find an FDM 3D printer in some public libraries; most of them have banned the printers from being used for dangerous and unsafe reasons. So, nowadays, these printers are generally used by licensed gun manufacturers and toy gun manufacturers. Now. Let’s discuss the legal status.

Legal minefield or incident of 3D printed guns

- The United Kingdom

In the UK, the Firearms Act 1968 bans gun parts and guns without government approval. The Home Office, a ministerial department of the United Kingdom Government, updates the Firearms Licensing Law rules to mention about 3D printed weapon ban. In 2013, police raided a Manchester gang and found some 3D printed gun parts.

- The United States

As per the Undetectable Firearms Act, the firearms that are unable to be detected by a metal detector are now allowed to produce such a legal production of weapons; for example, the Liberator needs a metal plate attached to the printed body. On 27th August 2018, the United States House of Representatives passed a bill following which the Undetectable Firearms Act was extended for ten years. Even though the Act was extended, it didn’t change any provisions. In 2014, 3D printed guns again gain attention when Netflix released a documentary named “Print the Legend.”

On 27th August 2018, a Federal Judge ordered Defense Distributed to remove the blueprint of a 3D printed gun from the site, and the legal proceeding related to this matter are still ongoing.

- Australia

The state law of New South Wales in Australia criminalizes 3D print firearms and the digital blueprint of the guns under the Firearms Act 1996, Section 51F. In 2015, during a raid on a meth lab, police seized a fully loaded 3D printed firearm. In another case, Since Sun was arrested for his connection with 3D printable guns.

In December 2017, he pleaded guilty to a few changes, like manufacturing 3D-printed firearms, possessing a blueprint of a 3D gun, and an unauthorized pistol. During his hearing, he informed the court that he wanted to replicate the Hollo videogame gun, and while searching for the blueprints online, he found blueprints of other firearms.

- Singapore

Singapore issued that persons who create a 3D printed gun or firearm in Singapore who don’t have a valid license to do that will be charged under the Guns, Explosive and Weapons Control Bill.

Risks associated with 3d printable guns

After the increasing popularity of 3D printed guns and 3D designs of different types of firearms, the government from various started assessing the risks related to this. The first and most crucial thing to note here is that 3D-printed guns don’t require identification codes, such as serial numbers or barcodes.

All the traditional firearms have serial numbers, and that helps in tracking down those owning these firearms. This allows law enforcement and other authorities to effectively regulate such harmful weapons. However, 3D printed guns cannot be traced.

On the other hand, to produce 3D printed guns, you don’t have to go through any background check. So, you can just go ahead and produce a gun using an FDM 3D printer. Here, the probability of getting the guns in the criminal hands increases even more. The biggest question here is, are these issues are only after the publication of 3D design files on the internet? Well, the answer is no.

As per various reports, such an issue has existed since the start of producing guns illegally. But it can be said that 3D printing has wide the existing loophole, offering all easier access. However, all licensed firms can produce 3D printed guns and gun parts to better make the final product.

Besides, gun toy makers also are using a gun 3D printer to develop sophisticated toy guns. If you have all the required licenses and want to improvise your gun production process, you can always go for the FDM 3D printers.

How 3D printing is applied to guns and gun models

Producing a gun can be very costly, and for that reason, you need to make sure that the final product will offer you the best result. You can’t waste a lot of money and material just to create a test piece of your gun. Besides, it also affects the duration of product development.

However, using a 3D printer, you can first create a prototype for testing purposes, and if all are good, you can develop the final product. This way, you can save money, time, and effort.

The 3d printed gun model will look very realistic, and you can know how your final product will look. But how guns and gun models are made? Keeping reading to ger your answer.

2.1, FDM 3d printer, the most suitable 3d printer type

In general, you will find two popular 3D printing technology in the market; these are; LCD and FDM 3D printing. However, when buying a perfect printer for producing a 3D printed gun, you can always trust an FDM 3D printer, and FDM 3D printed parts are quite durable than the LCD 3D printed objects.

FDM- Fused Deposition Modeling was first introduced during the 1990s by the well-known 3D printing solution provider Stratasys. FDM 3D printing technology is the registered trademark of the company.

The machine work by creating layers of filaments to produce the 3D object. The printing material is melted and process through the extruder. Then the machine will start creating a layer on the build platform.

Different types of filaments can be utilized with FDM 3D printers. Such materials are thermoplastic filaments like nylon, PAB, PETG, and more. Popular as the cheapest way to conduct 3D printing, FDM 3D printers are very cheap and efficient. This can be the ideal 3D printer for the firearm industry to produce gun models and parts.

FDM printing- The new technology of additive manufacturing

When people hear about “3D printing”, it will create some images of a tabletop gadget along with a spool of plastic 3D printing material, connected to a laptop or desktop. This is considered a perfect learning and training process.

However, technology has moved on, with 3D printing moving to an industrial scale, with the advanced techniques being managed to produce more complex shapes from the materials. Now, FDM printing is ruling the world of additive manufacturing.

How do FDM printers work?

FDM 3D printing in the firearms industry works by releasing heated printing material or filaments layer by layer process on the build platform for your general knowledge. The entire printing process has been divided into three major stages.

- The pre-processing stages

The machine comes with a built-in software called a slicer that slices the design and creates a CAD 3D design file. The software will also pick the ideal way to extrude filaments and the support materials.

- The production stages

Here, the filament is properly heated by the FDM 3D printer to convert the hard plastic filament into liquid form. Then the machine processes the liquid through the extrusion, and then the nozzle will start moving to begin creating layers. The process will continue until the model is completed.

- The post-processing stages

This is the final stage. Once the printing is done, the model is removed from the built platform and send for post-processing to give the object the desired shape. It may be noted that most all the FDM printers can use thermoplastic that is also widely used in the traditional manufacturing process.

This is perfect for applications that need toughness, high tolerance level, and better environment stability. Some significant aspects that make FDM printing popular are:

- The machines support industrial-grade thermoplastic that is mechanically stable.

- FDM 3D printing technology is well developed, clean, and very simple to us. Just add the instructions, and the machine will carry out the rest of the tasks.

- When it comes to achieving a perfect shape of various complex geometries, FDM 3D printing technology works great.

Exploring the benefits of FDM 3D printing in making 3D gun models and parts

The significant benefit is the ease of design. There is no need to think about what you should remove from the design. On the other hand, the technology produces a minimum of waste, and speed is also decent. In general terms, the only material consumed is what is used to create the 3D object.

What’s more? FDM 3D printing technique needs less level of setup work than the traditional model-making process. In the conventional manufacturing setup, the operator needs to program huge machines, use the right drill bits, and another tooling to carryout shaping and material removal.

In FDM, if the mod fits on the build platform of the 3D printer, it can generally be realized. The end benefit of the FDM 3D printing is a relatively cheaper process and low per-item cost.

It benefits the firearms designers enormously. For example, a perfect prototype of a gun can be produced rapidly. This, in turn, will facilitate the faster evaluation of the product and design alteration, if required.

Beyond rapid prototyping, FDM 3D printing can also be used to mass-produce final products. This is not possible in traditional manufacturing, where machinery stress can lead to product imperfection. You will get a product with inferior quality, and it will not be working correctly.

What’s more? The degree of precision in FDM 3D printing is much greater. In the firearms industry, the watchword is truly precise.

It is quite essential to make sure that the accessories are not affecting the gun’s impact point. On the other hand, you also need to make sure that the weapon’s critical components, such as the barrel, should produce one minute-of-arc or better accuracy.

With FDM 3D printing method, this can be achieved quite easily, and for this, you don’t have to spend a lot of money. As a result, you will enjoy greater profits, and your consumers will enjoy the cost-saving feature.

The higher level of precision of FDM 3D printing leads to a more aesthetically pleasing product, and there would be no divots, dimples, or tool marks, which is quite common in the traditional firearms manufacturing methods.

Who else prefers to use FDM 3D printers?

FDM 3D printers are used by industrial designers, the automotive industry, medical and dental industry, aerospace industry, R&D, and more to produce prototypes of different designs that they have in their minds.

While the product designers work on various types of toys, cars, furniture, and products, FDM 3D printers offer them an excellent flexibility level. On the other hand, they support different kinds of filaments, offering you the freedom to create anything you want.

The power of scenario visualization

The gun makers or gun model designers can easily manipulate multiple 3D models to do using 2D drawings.

They can analyze the what-if scenarios related to the 3D gun designs in 3D, which will help them validate their plans and detect the issue. With 3D renderings, you can save time and money as you can confirm the project requirements.

As discussed above, the 3D models can offer the designers an accurate picture of how they can change their designs if required. FDM 3D printers can facilitate effective and faster mass customization. So, get one now and witness how the machine is helping you in product development.

What is FDM printing mostly used for?

Well, it can be said that the utilization of 3D printing is extensively publicized, but what are FFF or FDM 3D printers used for? Many industries are now using FDM 3D printing, such as consumer goods manufacturers, automotive, and more.

The firearms industry is also using this for gun manufacturing. They use it as it positively helped to support their product development, their manufacturing, and prototyping process. Besides, they also use it as the thermoplastic used for 3D objects is perfect to create anything.

Prototyping

Before the guns are being taken to the field, the weapons must be tested properly. Therefore, thermoplastic filaments are perfect for creating prototypes as they can easily sustain mechanical stress, heat, and different types of chemicals. On the other hand, FDM 3D printers can produce highly complex objects, so it is ideal for making 3d printer gun models, 3d printed gun barrel and more. Besides, experts have stated that this is the best 3d printer for gun parts.

If you search for a viable option that can offer better results, FDM 3D printing can offer the best solution. For the best product, you can always trust Dreambot3D. The machines are competitively priced and can deliver the result effectively and efficiently.

2.2, Introduction to the working principle and development history of FDM 3D printer

With various types of Additive Manufacturing or 3D printing technology available in the market, it can be challenging for people or industries to choose which 3D printing technology will work well for creating a 3d printer gun model.

However, there is a common thing that every 3D printer follows. All printing processes require a 3D CAD file, which is then sliced into different layers and then converted into a 3D printer-readable format to carry out the print.

However, when choosing the best one, you can always go for an FDM 3D printer. Why let’s know about this printing in detail, and for this, we will start with the development history of an FDM 3D printer.

FDM 3D printing- The past and the current condition

FDM- Fused Deposition Modeling, or FFF, is one of the most popular and standard 3D printing technology that you will find in almost all industries. As the adoption rate increases across different industries, FDM has also emerged as the most revenue generated 3D printing technology.

So, what has propelled such a massive level of growth and maturity of this printing technology? How will it evolve in the coming years? Keep reading to know more.

A significant milestone in the development of FDM 3D printing

- It all started in the year 1989 when Lis and Scott Crump patented the unique Additive Manufacturing technique method and then trademarked it as

“Fused Deposition Modeling.” In the same year, they also established a company called Stratasys. - In 1991, Stratasys successfully commercialized its FDM 3D printing.

- The year 2005 marked the start of the RepRap project, which helped the company reduce the FDM 3D printing cost.

- In 2008, Stratasys informed that it would provide some machines, such as high-performance ULTE 9085 FDM printing material for its FDM 400MC and 900M FDM 3D printer.

- The 3D printing technology witnessed a major revolution in 2009 when the world’s first FDM patent expired. After that, some companies, such as Lulzbot and MakerBot, introduced their own FDM printers, and they witnessed a massive success in that.

- Following this, in 2011, Ultimaker established its FDM 3D printer manufacturing unit.

- Stratasys successfully acquired MakerBot in 2013 to expand the business.

- In 2013, Markforged initiated its business and introduced composite FDM 3D printing technology.

- In 2015, another well-known 3D printer manufacturing company, Voodoo, started its manufacturing process, and by the end of 2019, it built more than 200 FDM 3D printers.

- In 2017, Stratasys revealed the “Continuous 3D Build Demonstrator”, an advanced 3D printing machine used for faster production operations.

Exploring the origins of FDM printing

As per the data, FDM printing was first introduced during the 1980s as Scott Crump, an inventor, and engineer introduced a useful and effective rapid prototyping method. As discussed above, in 1989, Crump trademarked the technology with the name Fused Deposition Modeling and established Stratasys with Lisa Crump. Ion 1991, they launched the 3D Modeler, the first FDM machine.

With time, FDM 3D printing and printers have acquired a considerable level of traction while helping in low-cost rapid prototyping solutions. The modern FDM 3D printers follow the same method of creating a model through a layer-by-layer way to create an object as the first FDM printer did.

However, FDM printing technology has evolved many, and companies like Dreambot3D have introduced different advanced machines capable of completing a complex 3D printing task within a few hours.

The Introduction of the RepRap project and affordable FDM technology

The FDM 3D printing method’s extraordinary success can be explained with the help of the RepRap project. After that, many companies also introduced FDM printers for different purposes.

It was the RepRap project, an open-source concept, by self-replicating a 3D printer. First, it was adopted by the 3D printer DIY community. But the expiration of Stratasys FDM patent allowed other companies to utilize the RepRap concept to build FDM printers.

Evolution of industrial-grade FDM 3D printing materials

Experts have said that the FDM materials market is still young, but the market has dramatically evolved with time, pushing the printing material limit beyond standard ABS and PLA filaments.

Now, FDM 3D printer users can use nylon, PC, PETG, carbon fiber, composite, engineering-grade, and biocompatible grade materials to produce different types of 3D objects with different properties. The best thing is that today’s FDM 3D printers can also print PEEK and ULTEM like high-performance material.

These types of thermoplastics can be very rigid and difficult to process as they melt at a very high temperature. However, most modern FDM 3D printers have started with a high-temperature extruder to make it possible.

Different advancements in the field of FDM printing materials have been made possible as chemical companies across the world are now working hard to introduce new material. For instance, recently, Solvay introduced its PPSU and PEEK filaments.

These printing materials come with quite impressive properties. PPSU is resistant to impact, chemicals, and heat. On the other hand, PEEK is famous for its remarkable strength to weight ratio.

The wide availability of different durable thermoplastic types enables significant applications such as automotive bearings, gun parts, gun modeling, and more.

3D printing is considered the next major thing. In fact, it will become much bigger than the internet. Looking at the current condition, it can be said that 3D printing technology is very nascent;

It has influenced the global manufacturing and industrial industries. The technology is rapidly evolving, simplifying the production processes for all.

The working principle of the FDM 3D printer

FDM is a required method of additive manufacturing. Here, the layers of filament are perfectly fused together in a pattern to make the objects. The filament is melted in the nozzle and then slowly extruded on the built platform layer by layer. Let’s understand this better, and before moving to the process, here are some crucial components that an FDM printer comes with.

- Build area

It reflects the maximum size of the object that you can print using the printer.

- Filament diameter

It is the filament size you are using and can range from 1.7mm to 3mm in diameter.

- Hot end

It is an essential part of the 3D printer as here the filament is melted and then extruded in layers. You can go for PEEK-based hot ends, all-metal hot-ends, and nozzle. The most common one is the nozzle.

Here, you need to consider whether you should go for a smaller size nozzle or a more significant size nozzle. You can get a smoother finish with a small nozzle, accurate prints, ridge, and detailed print. On the other hand, a bigger nozzle can offer better reliability, faster printing, better layer adhesion, and more.

- Extruder

It feeds the material to the hot end. You may choose between Bowden and direct extruders.

- Heated bed

Heated bed is needed when working with high-temperature filaments, such as Nylon, ABS, PLC, and more. During the printing process, it keeps the material warm, leading to a perfect bonding between layers.

- Print bed

It is also known as the build platform on which 3D objects are made.

The process of FDM 3D printing

First of all, the desired filament is attached to the machine’s extruder. Once done, the extruder wills send the filament to the heater, where the hard plastic filament will be converted into liquid form for 3D printing.

This can be an essential stage as you will have to set the temperature based on different materials’ melting point. For example, if you are using nylon, the weather should be around 240 to 260-degree C. For ABS, you need to set the heater temperature at 210-degree C.

The melted material will move to the nozzle, and the nozzle will extrude the melted filament on the built platform in layers while moving in the X and Y direction. During the process, the print bed will move in the Z direction.

The same process of creating a layer will continue until the completion of the 3D object. Once done, the object will be removed from the bed, and post-processing work will be conducted. You can use vapor smoothing, sanding, support removal, polishing, hydro graphics, painting, and more for post-processing.

How to choose materials

To produce a perfect 3D gun model or toy gun using an FDM 3D printer, you need to choose the right type of materials. Even though real guns are made of metal, you can’t use metal for 3D printed guns.

The primary reason behind this is FDM 3D printers can’t process metal. Let’s talk about this in detail to get a better knowledge about 3D printed gun materials.

3.1, The materials used for real guns and gun parts

All most all the firearms are develop using aluminum, steel, plastic, iron, and more. Each material demonstrates its unique natural attributes and dramatically helps in better gun construction, covering the gun’s strength, aesthetics, weight, and more. Now, have a look at three essential gun materials used for real guns.

- Steel material

This is a widely-used material for producing guns. The gun manufacturers use heat-treated and high-carbon steel and are represented by the “Rockwell C Scale.” Tensile strength and compression are crucial factors to analyze the construction. Talking about modern gun construction is very cost-effective and efficient as computerized machines are used for this.

As it still is a versatile and durable material, it can create small parts and structures through injection molding and casting. Steel makes the gun to be more efficient and steadier. Chrome allows, or nickel plating is used to make the gun corrosion-resistant for finishing work.

- Aluminum material

Compared to steel material, using aluminum, you can lower the gun’s weight by around 35 to 40 percent. But remember that aluminum guns may not produce the same level of durability like steel-made guns as it lacks the tensile strength of steel.

However, for certain types of guns, this can be a perfect material. For example, some 9mm pistols. This type of gun requires lower tensile strength and compression. The gun will look aesthetically beautiful and feel very lightweight.

Some other materials that can be used for real guns

Polymer and plastics are used to create some components, such as rifle stock and handgun grips. Carbon fiber can also be used for a gun. For example, the .22 caliber Ruger rifle uses a steel barrel wrapped with a carbon-fiber barrel. This helps in maintaining the barrel strength.

In some cases, it has been seen that some guns come with parts made of brass. This material is used on barrels for the front sight or target sight. Some manufacturers use Zamak, which is a combination of aluminum and zinc. This material is used to manufacture guns that can use low-pressure cartridges.

Another popular material was Gunmetal. This is also called Red Brass. Speaking more about it, gun metal is one type of bronze that combines zinc, tin, and copper. There is around 2 to 4 percent of zinc, 8 to 10 percent of tin, and 88 percent of copper in terms of proportion.

Earlier, it was widely used to produce guns, but now it has been replaced by steel metal. This metal is resistant to corrosion developed by salt water and steam. The tensile strength of the material is around 221 to 310 MPa and melts at 1000-degree C.

However, the most common material used to make a real gun is steel, as this metal can easily withstand a pressure of around 60,000 pounds per square inch.

3.2, The materials used for the model guns

Model guns are available in different types and configurations. These can range from assault rifles, shotguns, machineguns, sub-machineguns, revolvers, pistols, and more. The earliest gun models came with a crude appearance and simple construction.

Today’s model guns can be classified into the “Cap Firing version” and “Display-only version (Dummy).” Most of the dummy editions replicate the internal mechanism and the real gun’s appearance with the moving parts.

On the other hand, cap-firing gun models can replicate internal mechanisms and appearance and fire the cartridge to create smoke, spark, and sound.

Taking about the structure, most of the model gun frames are made of materials; it can be all plastic or all metal. Zinc allows widely used to create a metal model gun. However, a new law was introduced in 1977 that regulated the production of metal model guns. After that, the plastic-made model guns became popular.

Plastic model guns are made from ABS-Acrylonitrile Butadiene Styrene). You can also use Heavy Weight plastic, such as PC – Polycarbonate, and HDPE- High-Density Polyethylene.

ABS offers an impressive level of impact resistance quality, and you can give it the desired shape utilizing little power. Besides, the material also responds to thermoforming.

Speaking about PC, it is 200 times stronger than glass and 20 times stronger than plastic. The material showcases a perfect balance of different types of engineering properties that make it ideal to be used under different temperatures while maintaining dimensional stability.

As this is a thermoplastic material, it can be remolded and reheated into different shapes as per your requirements.

After getting all the information, now you might be wondering which FDM 3D printer can work best for you? Keep reading to explore how to pick the right 3D printing machine based on your requirements.

How to choose a 3d printer to make your gun and gun model

When it comes to making gun models, you need to choose the right 3D printer. But this is where most people face the issue as they got confused about which printer to buy.

This chapter will offer you comprehensive information using which you can make the right decision.

4.1, Which machines are needed, and for what purpose?

In making gun models, you will need two machines, an FDM 3D printer, and another one is 3D scanner, which is optional.

4.1.1, FDM 3d printer

Even though LCD 3D printers are quite popular in 3D printing, these printers are not ideal for some 3D printing projects, such as durable and robust parts and rapid prototyping. This is where a 3D printer comes to play. An FDM can produce different types of prototypes and functional parts quite faster than other printers at a very low cost utilizing different types of materials.

Such printers can use nylon, PLA, PETG, ABS, PC, and other types of thermoplastic filaments to produce different parts. In a gun, you will need to create durable parts that can sustain heavy stress. An FDM 3D printer can be used to process ABS material to create different parts. It may be noted that the first 3D printed gun, The Liberator, was manufactured using this printing technology. So, you will need an FDM 3D printer to produce gun models.

4.1.2, 3D scanner (Optional)

Even though this is optional, a 3D scanner can be a useful machine when it comes to making a replica of real guns. You can scan any object using your 3D scanner and create the exact product from the digital design.

However, you may not need this in gun making as you can download gun model files from a different site, edit them, and create models from them. So, it’s up to you to decide whether you should buy it or not.

There are some other factors that you need to keep in mind while buying a 3D printer. Explore them all below.

4.2, How to choose the FDM 3D printer

It is a fact that selecting the right type of 3D printer can be a challenging task. But there are some factors, considering which you can make the choosing and buying process a little easier for you. Here, to help you with this, we have mentioned down some crucial factors that you should consider. However, if you have doubt, you can contact us anytime you want. Have a look at those factors.

4.2.1, What is the size of the print

Before finalizing the 3D printer that you want to buy, you need to consider the print size. In 3D printing, the size of the print will depend on the built platform that your printer has. As you are purchasing an FDM 3D printer for the 3D print gun, you can go for a printer with a small built area. If the object’s wall thickness is around 0.8mm, then an FDM printer will work best.

Besides, make sure that the printer has a decent size of built area. It is generally measured by, for example, 20-inches Wide (X) by 20-inches Deep (Y) by 20-inches High (Z). However, don’t go for a significantly smaller print area to save your money. This is where you can go for FDM 3D printers of Dreambot3D. All our 3D printers come with 400x400x400mm of built area.

4.2.2, Choose a reliable brand

It is always advisable to buy an FDM 3D printer from a trusted brand, for example, Dreambot3D. Why should you choose a reliable brand? When you are with the best company, you can expect to get the best 3D printers that are capable of producing quality 3D objects at an incredible speed.

If you go for an ordinary brand, you will have their printers with poor build structure and won’t last long.

Besides, there is no guarantee that you will get a better resolution. But with our printers, you can expect to bring 3D objects with a higher-level of details. In fact, our machines can produce better results while functioning at a higher speed. What’s more? As a reliable brand, we offer faster after-sale services.

4.2.3, Safety configuration of the machine

Recently, FDM 3D printers have been increasing in affordability and popularity. They are widely being used in shops, offices, laboratories, and industries. They have features that allow the users to create intricate parts that can’t be achieved through the traditional process. However, there are some risk factors associated with printers.

As the FDM 3D printers remain hot to melt filaments for creating 3D objects and remain hot during the process, you need to make sure that you are using them as per the mentioned instructions. Some other types of hazards are the production of nano-size or ultrafine particles, high voltage, heat, UVB light, chemical vapor, and more.

VOCs can be very harmful to all. So, make sure that the printer you are buying has an enclosed structure. Furthermore, it will be better for you to choose one with the temperature control unit. This way, you can lower the risk of getting affected by VOCs or other harmful elements.

4.2.4, Resolution requirements of the machine

In the industry of 3D printing, the resolution of an FDM 3D printer is generally measured by the size of microns. Talking about a micron, it is one-thousandth of a millimeter. By considering the printer’s resolution, you can have an idea about the printer’s printing quality. To understand this, let’s take an example.

If the 3D printer’s resolution is 200 microns and you want to print on the object of 2mm height over 10cm of distance, you will need ten layers to get the desired size. The resolution will depend on the printer’s nozzle movement and build an XY and Z direction platform.

Make sure that speed can be adjusted to get the desired resolution. FDM 3D printers come with two types of resolutions, one is Horizontal resolution, and another one is Vertical resolution.

Speaking about horizontal or XY resolution, this the movement the extruder of the printer can make within a layer on X-axis and Y-axis. Her, if the value is lower, you will get a higher level of details.

Coming to the vertical resolution, this talks about the minimum thickness of the layer that the printer can print in one pass. IF the thickness is small, the printed surface will be very smooth. But the printing process can take more time to produce subtle layers. In general, most of the consumer FDM 3D printers can create a layer thickness ranging from 0.2 to 0.3mm.

4.2.5, Consider whether the price of the machine is acceptable

FDM 3D printers are developed to meet your requirements related to producing 3D printed guns and toy guns. The cost of the 3D printers can range between USD 1500 to USD 20,000. But with price, the feature will vary.

If you are buying a costly one, then make sure that the printer has all the advanced features, such as printing speed customization, various material supports, easy to understand OS, constant heat production system, and more. As you will be spending a lot of money, make sure you will get the most out of it.

4.2.6, Consider the supplier’s after-sales service capability

Don’t choose a 3D printer supplier that doesn’t offer better after-sales services. As the 3D printers have complex electrical parts, they may suddenly stop functioning without any notice.

But you can’t take the risk of waiting for a few days to get the machine repaired by the experts. If the company has an excellent after-sales service facility, you can solve those issues instantly.

Always choose a company that can offer you 24×7 technical supports. What’s more? They will help you to keep your machine running smoothly for years.

4.2.7, Consider the service life of the machine

As per the 3D printer experts, a real gun 3d printer should work smoothly for at least 5 to 10 years. You can expect that when you have the best FDM 3D printers of Dreambot3D.

Made using advanced technologies and equipped with many unique features, our machines can stand out from the competitors’ machines in terms of quality and lifespan.

However, we would like to suggest that you should altogether avoid poor-quality material and follow all our experts’ maintenance tips. For any help, please feel free to get in touch with us.

4.2.8, Consider the maintenance cost of the machine

In general, an FDM 3D printer’s maintenance cost can be very high if don’t take proper care of the device. You may encounter a situation where you will have to replace liner bearing, fans, tubing, heat break, nozzle, and more. However, you can keep the maintenance cost low by taking proper care of your 3D printers. Besides, if you found a small problem, don’t neglect it and call us as soon as possible to get the required solutions.

Conclusion

You should 3D print a fully functional gun when you have a proper license. Otherwise, you can produce 3D printed toy guns that can be made using a 3D printer.

It is currently legal to build, own, and buy an 80 lower into a stripped AR-15 lower receiver in different countries. While some countries may require serialization and other types of application, but generally, it is safe to create.

However, you should always choose an FDM 3D printer for this instead of an LCD printer as FDM printers are known for producing durable 3D parts. Besides, you should consider 3D printing material properly.

Consider the information mentioned above, and you can easily buy the right type of FDM printer for you.

However, as a leading 3D printer manufacturer, Dreambot3D offers quality FDM 3D printers that can be used for producing 3D printed models and parts. You can buy our 3D printers at the best prices. If you face any issues and feel confused about the FDM 3D printers, please feel free to touch us.

Our detailed FAQ section can offer you more ideas about FDM 3D printing in manufacturing 3D printed gun models.

FAQ Guide

Is it legal to 3d print guns?

3D printed guns are a newcomer to the world of firearm manufacturing. In the year 2013, Defence Distributed, a non-profit organization established by Cody Wilson, introduced the first 3D printed gun on its official website. That enabled people to download the blueprint of 3D firearms for free. The digital plans are in the form of computer-aided design files, and their Introduction sparked a legal battle covering the U.S. government and more than twenty state attorneys general. However, talking about the law, The Bureau of Alcohol, Tobacco, Firearms, and Explosives allows people to manufacture guns at home but for personal use only. Besides, they also need to meet a certain specification for detectability and parts. Such as unlicensed guns or 3d printed guns that can’t legally be sold.

How effective are 3d printed guns?

There is no such valid data that can prove the effectiveness of the 3D printed guns. However, when 3D guns made of ABS plastic were tested, it demonstrated some exciting results. The same material is also used to create toys. The weapon managed to fire a .380 caliber round eight times. When it was fired, the bullet went around 11 inches into gelatin material. However, the original gun’s bullet traveled 18-inches. So, it can be said that 3D printed guns are effective. Besides, but better results prefer to use suitable quality filaments to 3D print gun parts or models.

What parts of a gun can be 3d printed?

Both the gun parts and guns can be 3D printed. The Liberator 380 was the first 3D printed plastic gun. This single-shot pistol developed through FDM 3D printing technology using the Dimension SST 3d printer from Stratasys. If you are wondering what types of parts can be 3D printed, here are some examples that you can consider. Some of the crucial models are raptor grip, the Cuomo mag, AR lower receiver, Feinstein AK-47 rifle magazine, Red Rocket shotgun slug, Fabrique Nationale P9 stock, AR-15 rifle muzzle brake, rifle suppressor, and more.

What are the advantages of FDM?

As per the current market data, FDM printers and printing are quite affordable. On the other hand, 3D printing materials such as filament are widely available and are relatively inexpensive. Using the right type of coding, you can easily create accurate and superior-quality 3D objects. 3D parts made from FDM 3D printers can be used for different applications as they are durable. When it comes to operating a 3D printer, you will find it is easy to operate an FDM 3D printer. Compared to other printing, FDM 3d printing is faster. Unlike LCD 3D printing, FDM printing allows you to different types of filament, as discussed above. The most significant advantage is for 3D gun production, an FDM printer works much better than an LCD 3D printer.

What is FDM used for?

FDM 3D printed parts are widely used for different types of applications across various industries. From companies in the medical maritime, automotive, aerospace to prototypes, all are adopting FDM printing. On the other hand, FDM is also used to produce different types of end-use parts, especially detailed and small parts, along with specialized manufacturing parts. Some types of filaments can be used in drug and food packaging.

How much does a 3d printer cost?

The rapid advancement in 3D printing technology has made the cost of the 3D printers very affordable. However, you can buy our professional and high-quality FDM 3D printer within USD 1500 to USD20,000. The printers work quite fast and produce superior quality 3D prints. For more details, please free to get in touch with us anytime you want, and we can offer you a free quote.

How long does it take to 3d print a gun?

Different factors can determine the time a 3D print will take to print a gun. For example, complexity, size, height, and the printing technology used for the parts. While some parts can be made within one hour, some parts may take a week to complete.

What does FDM mean in 3d printing?

Fused deposition modeling (FDM) or FFF- Fused Filament Fabrication printers function by releasing different filaments made from thermoplastic, for example, ABS, PLA- Polylactic Acid, Nylon, PETG through a nozzle, by turning the rigid material into liquid and then applying the filament layer by layer on the print bed. The process will continue until the part is finished. Such printers are perfect for modeling and faster prototyping of different parts.

Is it hard to learn 3d printing?

Instead of hard, it can be said that 3D printers are quite challenging to learn. The reason behind this is before using it; you will have to learn a lot of things about the 3D design software, slicing, 3D printing materials, post-processing technique, and more. Besides, you will have to develop the skills to manage the printer and its parts and make sure that they are working with perfect coordination. Learning all these things can be challenging, but you can develop the skills with 10 to 30 days if you try.

Do FDM printers smell?

Yes, while using 3D printers or a gun 3D printer, you may witness a noticeable smell as they use heating technology to melt filaments to create objects. These filaments are made of different types of materials, such as PETG, nylon, ABS, PLA, PC, carbon fiber, and more. When they are heated up, these materials give off a strong smell. You should remember one thing, all printed materials are non-toxic, but some have some smell. So, while printing, make sure that the machine is placed in a well-ventilated area and you are following all the required precautions. For more details, you can get in touch with our experts.

Where can I find 3d printed gun files?

The most popular extension used to 3D print guns is STL. So, while searching for 3D printed gun files, you should search for best 3d printed gun STL file. However, some of the best websites to download such files are:

- GrabCad

- Cults 3D

- Free 3D

- Clara.io

- CG Trader

How do FDM 3d printers work?

The working process of an FDM 3D printer is straightforward to understand. The entire printing begins with a 3D Computer-Aided Design model. Using slicing software, the digital 3D model is divided into different slices, or you can say layers and produces a G-code file that a 3D printer can process. The 3D printer now heats the plastic filaments and melt the material. After that, the melted filament is extruded through the nozzle, layer by layer, onto the printer’s-built platform. The thickness of each layer can be around 0.1mm to 0.5mm based on the printer’s resolution.

What guns can be 3d printed?

Plastic guns and toy guns can be 3D printed using an FDM 3D printer. For example, The Liberator was the first 3D printed gun. The weapon was made of plastic. However, you can also create a 3D printed gun through metal 3D printing. But for this, you need to use other types of printers as FDM 3D printers can process metal. You can 3D print sniper rifles, shotguns, pistols, revolvers, sub-machine guns, songbird 3d printed guns, and more. But acquire all the required licenses before 3D printing a gun. However, to create 3D printer toy guns, you don’t have to get any licenses.

What is a 3d printed plastic gun?

As the name suggests, 3D printed plastic guns are assembled from parts made of ABS plastic. This plastic can also be found in Legos. Such firearms can be 3D printed using an FDM 3D printer. The first 3D printed plastic gun was The Liberator, a handgun. The weapon was introduced by Defense Distributed, and they made this using Stratasys Dimension SST FDM 3D printer.

Are 3d printed guns reliable?

Well, there is no exact answer to it. If you compared, 3D printed metal guns are more reliable and robust than 3D printed plastic guns. In 2013, the U.S. Bureau of Alcohol, Tobacco, Firearms and Explosive’s agents tested some 3D printed guns. They found that the quality of manufacturing and materials can determine whether the weapon can fire multiple rounds or not. They created guns using the gun model blueprints and durable grades of resins. As per the data, the high-end 3D printers completed the printing task within 10 to 18 hours. The gun made of low-grade plastic broke down into pieces after firing just one bullet. However, the 3D printed gun made of high-quality resin managed to fire eight bullets. Besides, they did the same amount of damage, just like metal guns.

Do plastic guns exist?

Yes, a plastic gun exists. The firearms industry makes plastic gun models test the design’s effectiveness and then produce the original product. Besides, you can also find 3D printed plastic toy guns. The fact is that anyone who has the right type of equipment and material can easily make plastic guns that can really work.

Can you 3d print an AR 15?

For an answer, you can consider the statement given by Cody Wilson. He said that no one couldn’t 3D print an AR-15 gun. It may be noted that here the A in AR does not mean Assault; it stands for ArmaLite. Instead of that, one can print the AR-15’s lower receiver and magazines. These parts can successfully fire multiple rounds of real bullets without breaking apart or developing any crack.