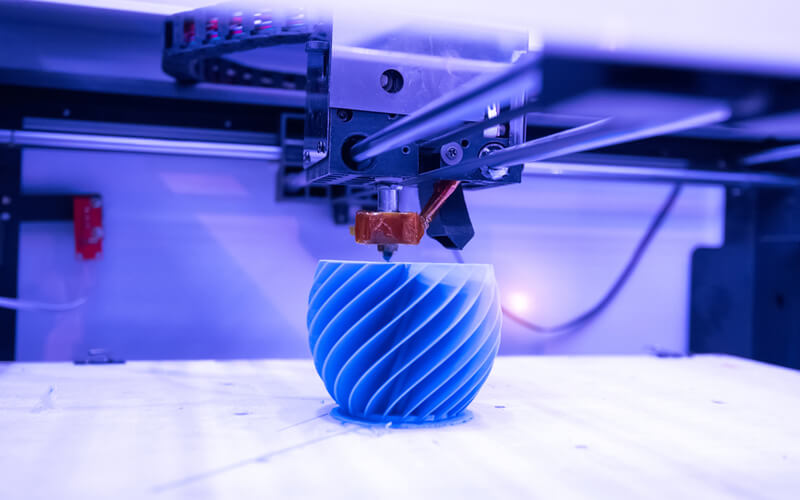

FDM 3d printer

We are a factory that produces high quality FDM 3D printers for 3D printing for different applications. The FDM 3D printer is used in medical, dental, aerospace, automotive industries, etc.

The FDM 3D printer is affordable, prints highly accurate 3D prototypes and makes use of affordable printing materials.

Contact Us

industrial FDM 3D printers

- The printing accuracy is up to 0.05mm that makes all printed prototypes highly smooth and accurate.

- The FDM 3D printer uses materials such as ABS, PLA, nylon, TPU, PVA, PC etc.

- The printer supports small to large sizes of printing of up to 1000x1000x1000mm.

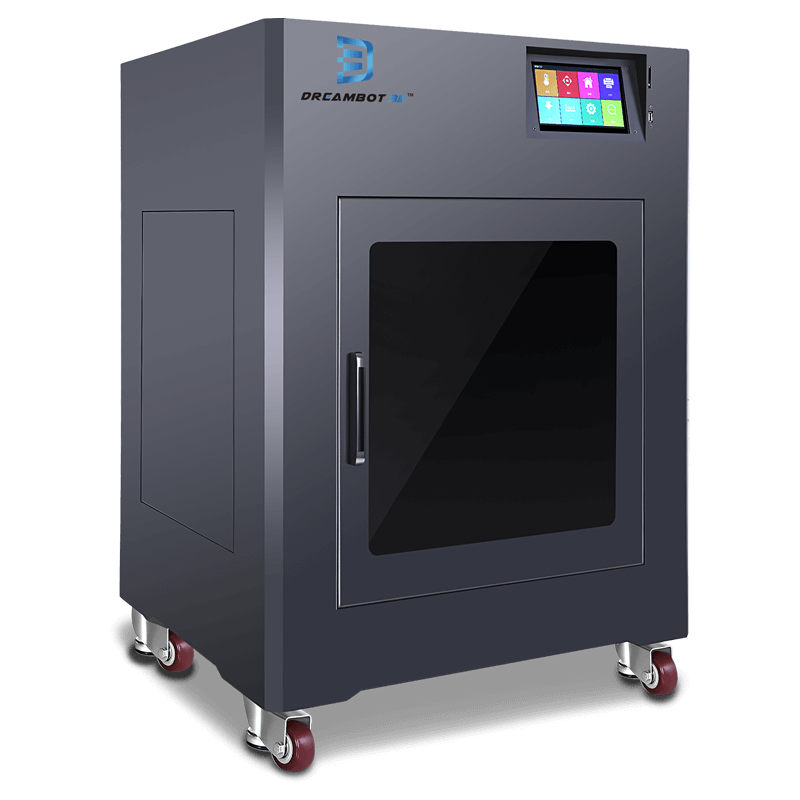

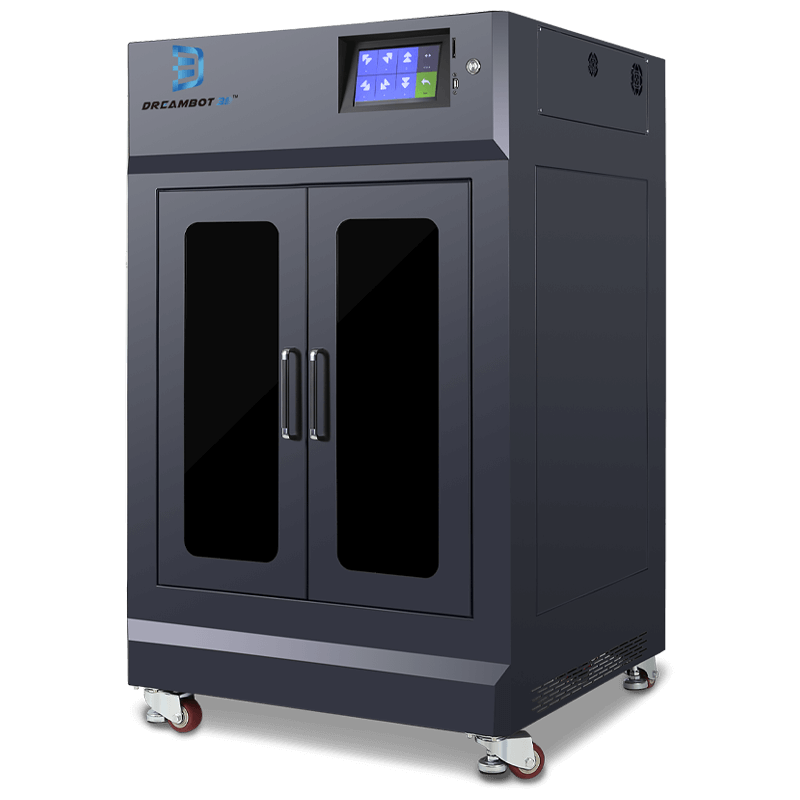

Dreambot3D industrial FDM 3D printers list

The L-200 3D printer is a desktop level FDM 3D printer with the printing size of 210x210x210mm.

The L-300 3d printer prints at a speed of 20 to 150mm and printing size of 300x300x300mm.

The L-400 3d printer prints at a speed of 20 to 150mm with a printing size of 400x400x400mm.

The L-500 3d printer prints at a speed of 20 to 150mm with a printing size of 500x500x500mm.

The L-600 3d printer prints a layer thickness of 0.05 to 0.3mm and 600x600x600mm size.

The L-800 3d printer prints a layer thickness of 0.05 to 0.3mm and 800x800x800mm size.

The L-1000 3d printer prints a layer thickness of 0.05 to 0.3mm and 1000x1000x1000mm size.

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

6 points why choose us

Automatic resume printing

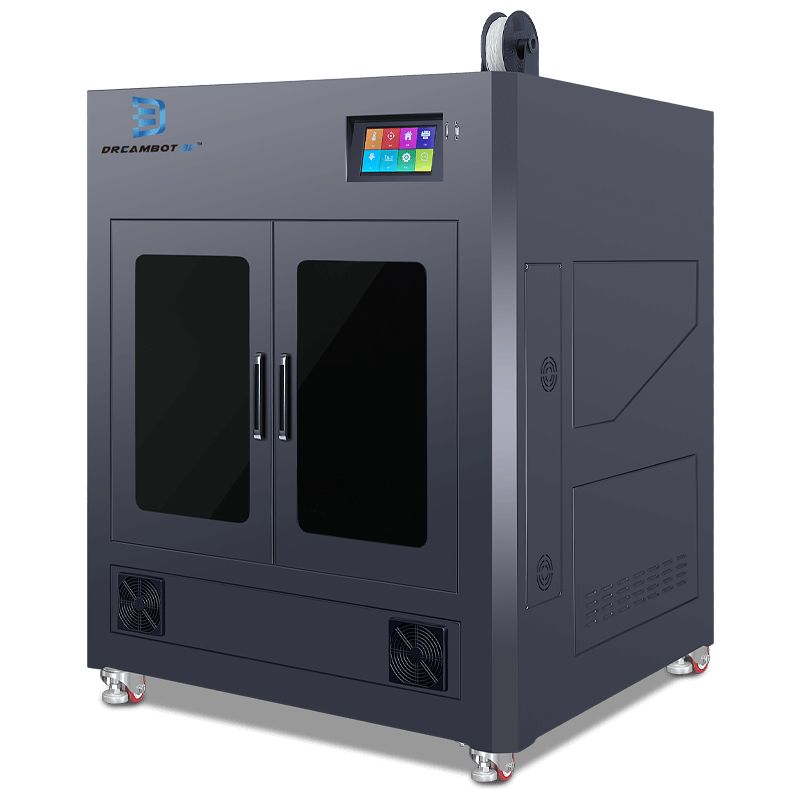

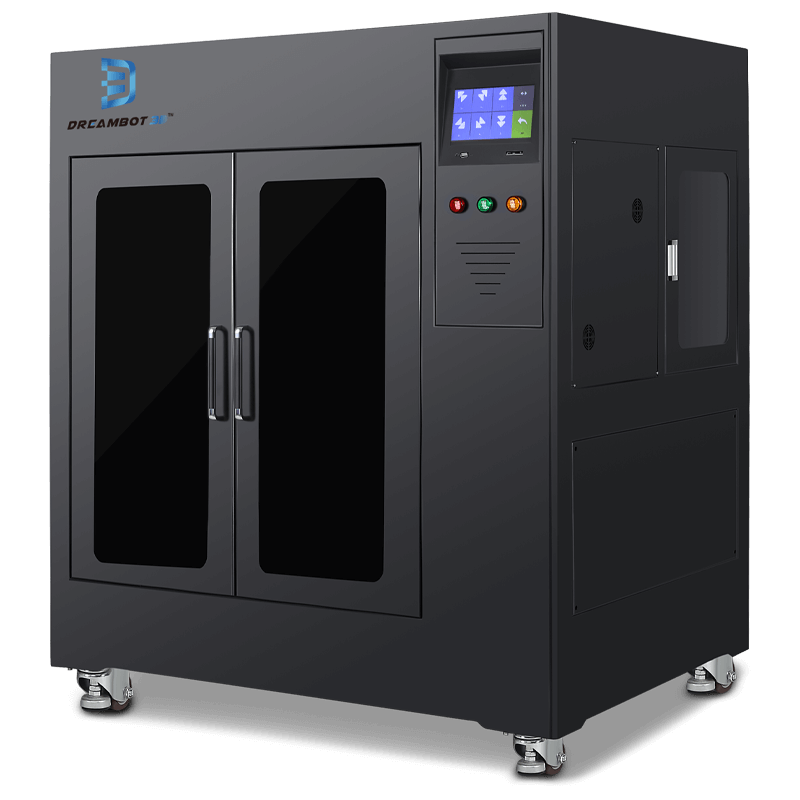

Full enclose stable frame

The whole machine case is thickened by CNC cutting, with accurate hole position, better assembly stability, and higher positioning accuracy of printer operation.

Allow offline printing

Use U disk or SD card to print without connecting to a computer to print. After starting to print, the data is automatically saved and the U disk or SD card can be removed.

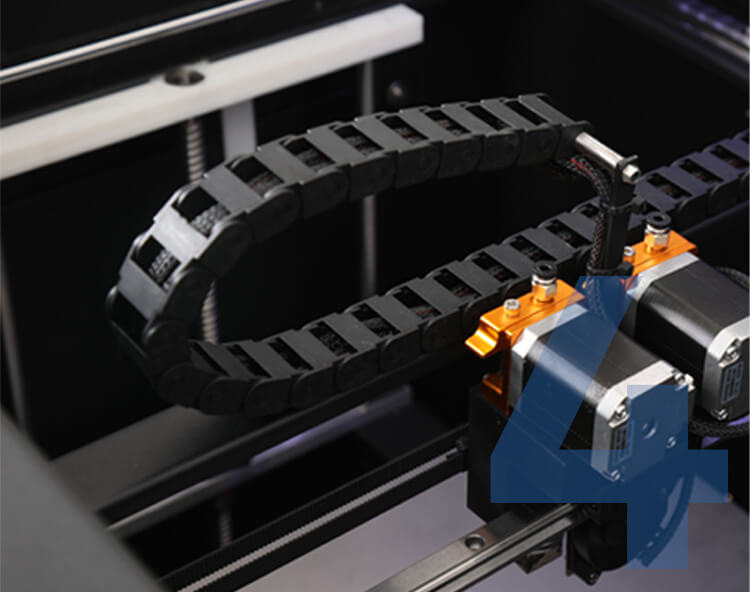

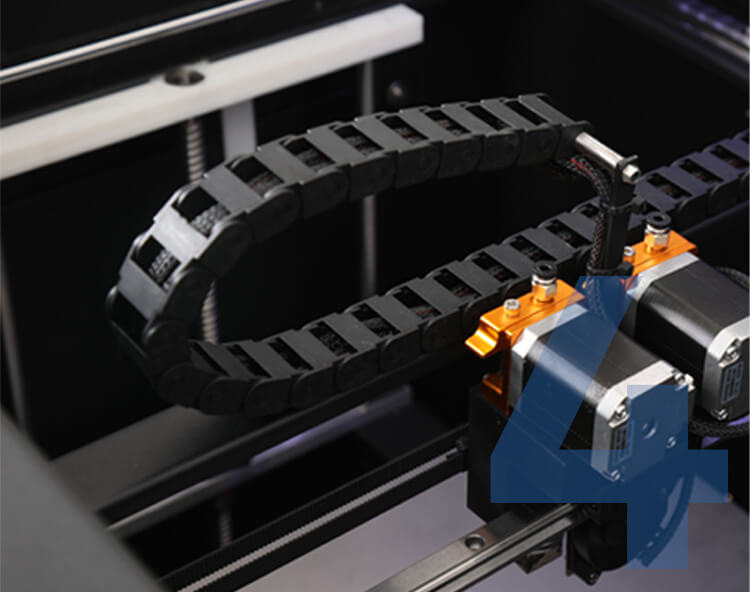

Drag chain wiring design

The wire is installed in the inner casing of the drag chain to effectively ensure that the wire will not be damaged for a long time when the printer moves at high speed.

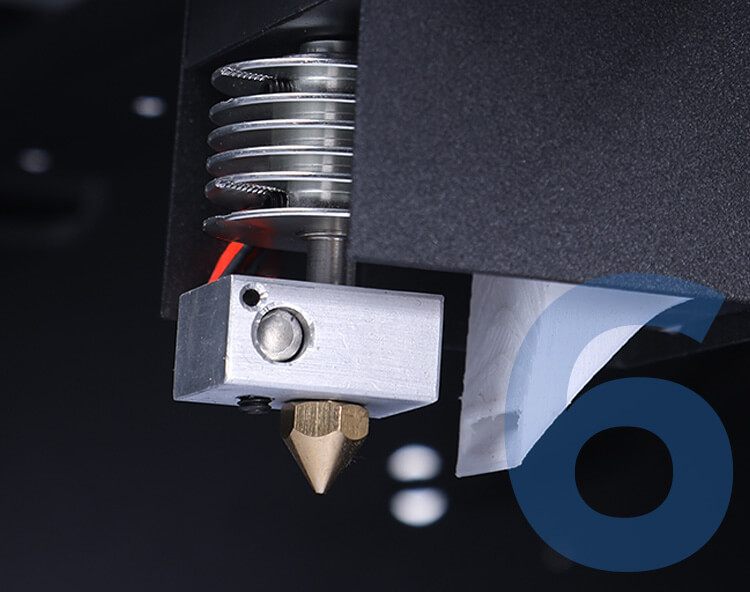

Precision ball screw

Using the latest Taiwan ball screw, it has higher straightness, lower friction coefficient, better smoothness, higher positioning accuracy and more stability during printing.

Alloy nozzle

Independently developed a unique bullet nozzle with uniform heating and a patented head assembly, so that it can work smoothly without interruption.

What Our Customers Say

FDM 3D printer buying guide

FDM 3D Printer Introduction

We know what it’s like to have come across multiple 3D designs and fallen in love with the efficient and accurate printing FDM 3D printers provide. Still, you are yet to build the confidence to try out your own model due to the bowels of technical jargon attributed to the FDM printer’s buying and printing process.

We optimized this buying guide to direct your buying decision, help you understand the dos and don’ts of the market, navigate suitable FDM 3D printers, and kickstart your printing journey.

But before we get into all that, we need to ensure we on the same page as to what FDM means and what the 3D printer is capable of doing.

If you have been in the printing industry for a while, we believe you wouldn’t have a hard getting around this definition. Fused deposition Modelling {FDM} printers or Fused Filament Fabrication {FFF} printers {as they were formally known till the FDM term was trademarked by Stratasys in 1991; the company behinds its first design} are machines built to deposit melted material in a pre-determined path, layer-by-layer selectively.

For the newbies and individuals looking to build a sustainable source of income from 3D printing using FDM printers, Fused Deposition Modelling {FDM} printers are 3D printing machines that create images one at a time. FDM printing process revolves around a three-dimensional output. Each layer of the material you are printing is placed on top of another again and again till a finished product is acquired.

Unlike most other printing machines, FDM 3D printers are quite easy to setup. You don’t have to read through bulky manuals or possess years of experience in the sector to be able to navigate your way around an FDM machine. Most FDM printers are designed to provide a smooth and efficient printing process right out of the box—no research, no frustration, no adjustment.

And just like every other 3D printing machine providing highly valued innovative services to individuals around the globe, there are capabilities and limitations users need to keep in mind when using an FDM machine. To skip through the noise, let’s break down the printer’s bulky operational sequence by exploring its working principle.

1.1, Principle of FDM 3D Printer

FDM 3D printers are machines with strips that keep the plate from moving while in transit. Most FDM 3D printers come with a small interactive screen that’s flexible to touch and bold enough to read. Before we formally dive into FDM 3D printers’ working principles, let’s look at some of its basic parts.

The Printer platform: an FDM 3D printer platform is made of either metal, ceramic or hard plastic, depending on the manufacturer and product purchased. This platform serves as a base for each successive layer.

Raw Material: while detailed info on the types of materials that can be printed on using an FDM 3D printer is detailed in the next section, it important you keep in mind that the raw material commonly used for FDM 3D printing is production-grade thermoplastics.

Printer Head: the FDM 3D printer head, also referred to as nozzle, is attached to a mechanical chassis. The nozzle is commonly controlled via a belt or leads screw system. The Printer head melts and extrude filament material and deposit an object layer-by-layer according to a CAD design.

Working Principle of FDM 3D Printers

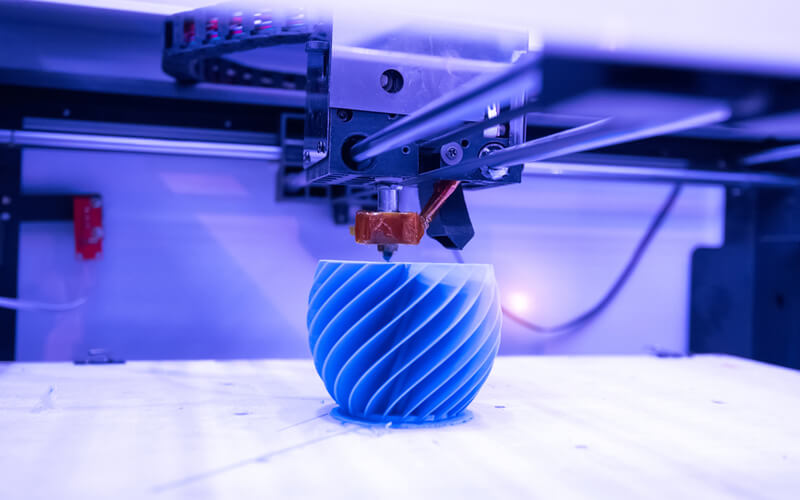

For an FDM machine to function properly, it requires a heated nozzle, a build platform, and raw material to build upon. The printing process begins after the modeling software slices the 3D CAD file creating an extrusion path for the nozzle to follow. All necessary support needed by the object is factored into the extrusion path, and the nozzle movement is controlled via the interactive interface found on the machine.

When the software successfully determines a suitable path for the nozzle, the filament is let loosed and fed through the heated nozzle. As soon as the raw material gets to the nozzle, it dissolves to a semi-liquid state and is forced out of the nozzle in the form of super fine beads. Immediately after the material leaves the nozzle, it hardens and bonds to the layer under it.

Using the FDM machine’s mechanical interface, you can lower the platform holding the material to about one-sixteenth of an inch, giving room for the nozzle to start working on the next layer. Note that to remove the object or model created from the platform, you have to either break them off or use a solution of detergent and water.

1.2, What Materials Can Be Printed by FDM 3D Printer

Whether you are looking for a desktop plugin and play 3D printer or printers with a custom button that easily loads and unloads the filament, Dreambot’s got you covered—more details on that later. For now, let’s look at some of the materials that are commonly used to print objects via FDM printers.

Thermoplastic materials stand as the most viable printing material for FDM 3D printers. Thermoplastic materials are preferred because of the malleable nature they possess when heated. This remarkable feature gives room for each layer to stick together during the creation process.

Note that when printing big objects with thermoplastic material, you might require support to prevent the material from tipping over. However, that shouldn’t be a source of concern—you can 3D print the support needed using an FDM printer before kickstarting the process.

There are different types of thermoplastic materials available. The best depends on the object you want to print and the type of FDM machine available. This buying guide is geared towards helping you make the best buying decision all around. Below is a listing of some of the notable thermoplastic material available and the pros and cons attached to usage.

- Polylactic Acid {PLA}

Polylactic acid PLA is a biodegradable and bioactive thermoplastic polyester made from natural products like corn starch. The environmentally friendly filament possesses layers that, if deposited accurately, would provide a remarkable finish.

PLA comes in many colors, is easy and fast to print on, and is not susceptible to shrinkage. On the downside, the finished product possesses bad UV light resistance and can sometimes cause nozzle clogging.

- Acrylonitrile Butadiene Styrene {ABS}

Want to create 3D designs of everyday objects? Acrylonitrile butadiene styrene is an amorphous polymer viable not only for carrying out everyday printing tasks but also as a support material when printing on filaments that require extra strength.

ABS filaments are recyclable; the finished product is stiff and durable and is resistant to abrasives. While the ABS filament is a great choice for creating smooth and well-machined models, bear in mind that the finished product is UV sensitive and does smell bad when heated.

- Polyethylene Terephthalate {PET}

Are you looking for an FDM printing material that brings multiple advantages to the prototyping and production process? Polyethylene terephthalate is a thermoplastic polymer resin of the polyester family suitable for designing anything and everything.

From table stands to clocks, bottles to cloths, you can use the PET filament to design reputable 3D models. PET finished products are moisture-resistant, flexible, and possess nice and smooth looking layers. On the downside, this not-to-hard to print on filament can change color during the printing process and have a reputation for polluting the ocean.

- Thermoplastic Polyurethane {TPU}

When flexibility matters, chose Thermoplastic polyurethane. TPU is a rubber-like material that can be used to make semi-flexible parts using an FDM 3D printer. This filament is renowned for its formidable resistance to abrasion.

You can use a thermoplastic polyurethane finished product at a temperature well above 176° F, certain you wouldn’t encounter shrinkage or breakage. Note that TPU is made of soft and hard segments making it hard to print on and difficult to post-process.

- Polycarbonate {PC}

Need to create 3D models or designs for projects in the construction, aircraft, or medical industry? Polycarbonate filaments are designed to do justice to such a task. PC is a thermoplastic polymer containing carbonate groups in its structure.

The filament is comparable to ABS in terms of makeup and structure and is regarded by most specialists as a viable replacement. Designing 3D models on a polycarbonate material using FDM 3D printers would grant you access to a finished product that can be sterilized, that’s transparent, strong, and durable. PC filaments are hard to print on, and their finished products are UV sensitive.

1.3, Why is Dreambot’s FDM 3D Printer So Prominent?

We have talked about how FDM 3D printers work, the principle behind the printing process, and materials that can be printed on using an FDM 3D printing machine; we think it’s high time we focused on what makes Dreambot’s FDM 3D printers a prominent option in the global market.

From how our printers are built with software that makes it easy to re-orient scale and flip model, to its table default settings for slicing and its resume printing function; this section covers it all. We advise you to opt for a relaxed position as we explore the countless advantages and benefits our FDM 3D printers bring to the industry.

To not bore you with too many details, we will only highlight ten features/benefits you get to enjoy from purchasing an FDM 3D printing machine from our store.

Print Unfinished Models Whenever You Want

Whether you just experienced unexpected power failure or an emergency call is about to take you off the job, our FDM 3D machines got you covered. Our FDM 3D printers are equipped with humanize continuation mode + automatic memory function that keeps them operational at all times.

Its humanize continuation mode helps save you from the embarrassing situation of an unexpected power failure by recording and saving the last known printing data. In contrast, the automatic memory grants you access to continuous printing immediately after the machine is turned on.

With Dreambot’s FDM 3D printers, you don’t just get to enjoy a high level of smoothness and efficiency; you also get an added bonus of a detailed and time-saving printing process.

Automatic Recognition System for Broken Material Detection

Printing with an FDM 3D printer is fun and easy. While this is a good thing, it sometimes makes users lose track of the printing process. Many individuals in the printing industry, both professionals and hobbyists, would easily agree that at one point or another, they forgot or often forget to change the material while printing—leaving the models at the risk of getting broken.

To combat this issue, all our FDM 3D machines are built with an automatic recognition system that automatically pauses the printing process and raises a flashing red light alarm each time you fail to replace the model. That’s with our FDM printer; you need not worry about material waste or breakage.

Drag Chain Wiring Design

If you have been in the printing business for a long time, you know how frustrating and annoying encountering issues with your FDM 3D printer wire can be. The protective wire in most FDM machines is prone to damage when the printer operates at high speed for a long period.

This issue has plagued the industry for quite a while, causing unexpected delays and sometimes extra expenses for hobbyists and professionals alike. At Dreambot’s, keeping our clients satisfied in the most cost-effective way is a highly valued priority. Our FDM 3D printers come with a drag chain wiring design; that’s, the protective wire is installed in the drag chain’s inner casing granting it access to play a protective role.

Stable Frame Design

For every FDM 3D printer, accuracy and stability is key to an efficient printing process. All our machines are designed via CNC cutting and forming. The sturdy frame design is optimized to give the machine a precise hole position and a better assembly process that keeps the printer printing with detailed accuracy even when operating at high speed.

Precision Ball Screw

We don’t provide our clients with machines that help them enjoy a stress-free, smooth and efficient printing process just to stamp our credibility in the global market—these goals are tied to our company mission, vision, and values. All our FDM machines come with newly upgraded Taiwan ball screws. Compared with the regular T-shaped screw, the Taiwan ball screw proffers higher straightness, lower friction coefficient, better smoothness, and more stability.

Wide and Thick Aluminium Profile Guide Rail

Better is always best, and the continuous advancement in technology provides room for better daily. At Dreamsbot’s, our experts are not only known for the remarkable designs and influential creations they bring to the industry; we also possess ideals minds leading the innovative bandwagon in the printing industry.

All our FDM 3D printers come with a newly upgraded sliding system with a wide and thick aluminum profile guide rail. This innovation helps you obtain an FDM machine with higher bearing capacity, increased speed, and a printing experienced backed by exceptional accuracy.

Indicator Light

Convenience determines reliability as well as proficiency. Carrying out a 3D printing task in a machine not equipped with convenient features can keep on a rocky edge all day long. All our FDM 3D printers are built with indicator lights. The Indicator light is convenient for checking the operational status when printing. The indicator light is located at the top of the machine, and the light’s material can be replaced in time when used up.

Offline Printing

Many individuals have raised countless complaints about inserting their memory card into an FDM printer each time they want to print, just to find the printer unresponsive. While the recommended procedure in such cases is to format the memory card and try again, we wouldn’t want our clients to encounter such issues.

Our FDM printer’s grants users access to offline printing. Printing with a U disk or SD card does not need to be connected to the computer for printing. With our machines, after every printing process, your data is automatically saved. So, whether the U disk or SD card is inserted or not, you can create 3D models of previously printed designs.

Refined Feeding Structure Process

Our FDM machines come with a well-designed process feeding structure possessing a relatively low requirement for the extrusion stepping motor’s torque. The interactive control interface and easy to navigate controls makes it possible for users to load and offload the printing platform with just a click of a button. Dreambot’s FDM 3D printers are built with a refined feeding structure that guarantees stable extrusion control, more accurate feeding, and convenient for users to change materials.

Improved Printing Environment

Our FDM 3D printers are optimized with a glass door that helps control airflow inside the printer. This printing environment is paramount to obtaining better printing quality, reliability, and security. The new anodized aluminum template our machines come with also provides a more reliable printing experience for engineering materials. Using our FDM 3D printers enables you to enjoy a more consistent surface finish daily.

Application field of FDM 3D Printer

FDM 3D printers come in a variety of coaster designs, each built to tackle specific needs. While most FDM printers go by the same working principle and are suitable for 3D printing multiple materials in different industries, the use and application of FDM machines in these industries are different.

Since you have stuck with this buying guide thus far, we think it’s safe to presume that you need the best FDM 3D printer. And since determining the best FDM 3D printer means knowing where and how you want to use the machine, let’s take a look at some of the prominent fields where FDM 3D printers are held in high regard.

2.1, For Industrial Research and Development

Research and development is a vital part of every industry. No innovation, whether in technology, or medicine evades the research and development phase. From data visualization, rapid prototyping to product development—all the task involved in design and manufacturing falls under the research and development phase.

Now to the big question; how are FDM 3D printers influencing the research and development process in numerous industries? FDM 3D printers are used to create prototypes that demystify complex R&D procedures. Industrial research and development comprise of multiple phases. The dynamic intricacies involved can become complicated, especially in situations where many individuals are involved in the task.

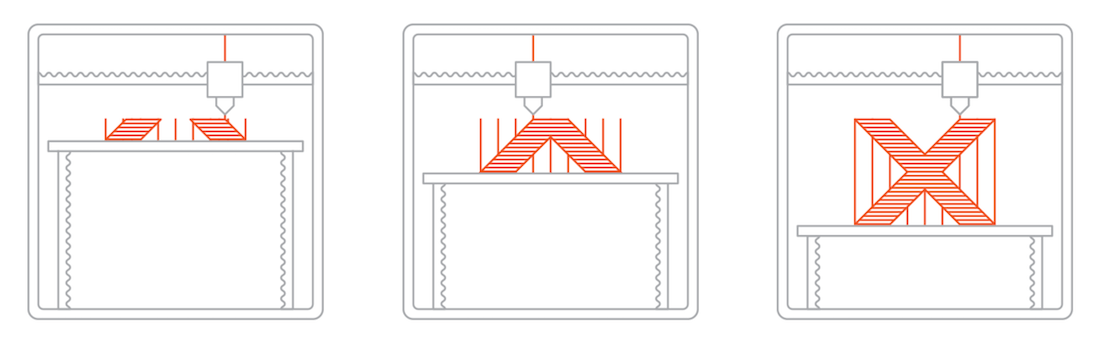

FDM machines can be used to design 3D models that keep the team in check and streamline the manufacturing process. An FDM 3D printer grants users the opportunity to play around a bit while printing in different orientations in other to get the best way to do it. R&D is all about innovation. With FDM printers granting its users the ability to create objects and designs of multiple variants at low cost, it’s undoubtedly a must have for every research and development task.

Having a professional FDM printer when carrying out a research and development task can help you highlight potential risk areas early on. FDM machines allow you to prototype and test small components within a limited time quickly. The machine helps designers access design frameworks and operation sequence conventional R&D processes doesn’t leave much room for.

If you run an R&D team whose day to day workload Revolves around developing products set to break boundaries and exceed previous expectations, then you wouldn’t want to miss out on the remarkable features our FDM printers are offering. Note that FDM 3D printers are also cost-efficient machines for individuals in the R&D industry.

2.2, For the Production of Animation Figures

Everyone loves a good old cartoon character. From Elsa’s journey in Frozen to Moana’s ordeals, cartoon characters and animations are making waves all over the globe. However, to create animation figures, you need a technology that provides a distinctive edge in design freedom and flexibility while allowing you to visualize every step of the process.

3D printers are at the forefront of the cartoon and animation industry, and FDM 3D printers are currently leading the bandwagon. To further demystify FDM machines’ impact in the animation and cartoon industry, let’s look at the two major advantages FDM 3D printer’s usage in the industry have brought about thus far.

Provides a Meticulous Edge to Detail: if you have ever tried creating a 3D design of any object, or let’s say try to stitch two different materials together, you would know how important meticulous attention to detail is.

Creating animation is a very complex task. From the design phase to prototyping to the end product, you can’t afford to slip out any detail—missing out on even the smallest element can hinder the portability and flexibility of the end product.

FDM machines are regarded as a durable option for creating animations because it grants designers the opportunity to pay meticulous attention to detail while leaving room for even the most minor editing to be carried out. With the best FDM 3D printer at your disposal, you can streamline an animation creation process; rest assured, accuracy is guaranteed.

Time-Saving and Cost-Effective: animations nowadays are extremely detailed. Many animation lovers find it arguable that every single part, feature, or attribute inculcated in their favorite cartoon characters was detailed down during the design process.

The development process involved in using animations to create a movie is extremely different from having humans act. Unlike humans, animations don’t possess instincts or inbuilt characters—that’s every animation you have ever come across, be it in movies or on social platforms, was thoroughly thought about, detailed, and designed. Imagine the countless hours manually designing an animation would take? Then think of the cost?

The introduction of FDM printers in the animation industry made it possible for designers to create complex elements within a limited time frame. Top FDM printers don’t just make the process faster but also ensures that users get to obtain high-quality end product at a minimal cost.

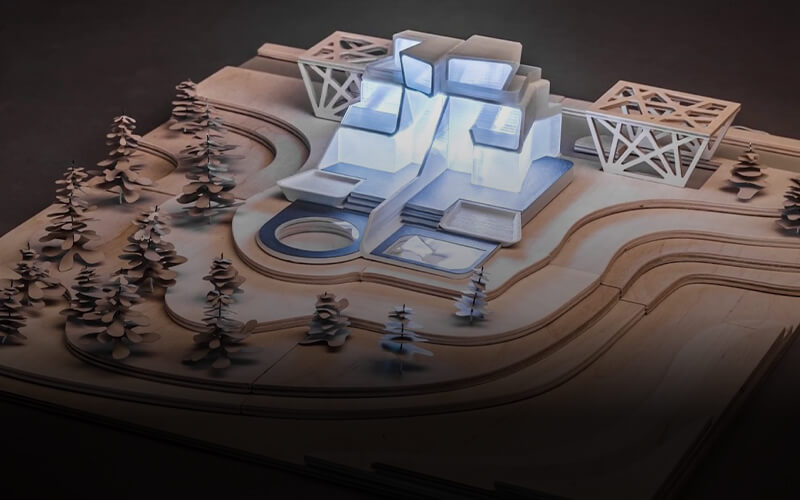

2.3, For Model Making

It’s never a funny sight to have a design perform below peer when placed in the spotlight for public display. To avoid scenarios that would make you want to hide your face in shame, testing your design’s functions, aesthetically and structurally, is quite essential. 3D printed pieces are regarded as highly influential models for product designers. Ranging from fashion to medicine, model making runs rampant.

While the notion of creating 3D models before designing the real product might seem expensive and unnecessary at times, the downside of not having one is quite catastrophic. 3D models help you understand the design and production sequence. Whether you are trying to navigate your way around an architectural project of a 50 story building or looking to design a sustainable mannequin for your next fashion exhibit, creating a model to interlinks the design phase’s integrity to the end product is necessary.

Now to some simple yet highly neglected questions; what sort of 3D printing machine is suitable for making models? Can I use the machine I used in creating a drone model to design a high voltage power transmission model? Are 3D machines expensive, and which type would allow me the flexibility to create models of different shapes and sizes across numerous industries?

What sort of 3D printing machine is suitable for making models?

The best 3D machine for making a model is the FDM 3D printer. The FDM machine is amongst the few printers built to sustainably cater to all your printing needs at a low cost. The printing machine is simple to use and easy to set up. Purchasing an FDM machine from our catalog would enable you to enjoy a smooth and efficient 3D printing process right out of the box.

Can I use the machine I used in creating a drone model to design a high voltage power transmission model?

Regardless of your industry, the model you are trying to design, the material, or the processes and stages involved in the designing process, Our FDM 3D printer got you covered. The machine is optimized to provide a simple yet detailed printing experience. Be it an FDM 3D printer for a high voltage power transmission model, drone model, mannequin, medical model, or ship terminal model—our catalog has it all.

Are 3D machines expensive, and which type would allow me the flexibility to create models of different shapes and sizes across numerous industries?

FDM 3D printers are regarded as the best printers for individuals on a budget. There are different variants available. While every FDM printer available in our collection is fully equipped to cater to modeling tasks of different ranges and sizes, it’s advisable you speak with a support representative if skeptical about making a purchase.

2.4, Used in Aerospace and Automotive Industries

The aerospace industry is regarded as one of the earliest adopters of 3D printing tech. Its usage in the industry dates as far back as 1989, and since its introduction, its dominance has increased rapidly. Designing an aircraft generally requires hundreds of fixtures, guides, templates, and gauges of different ranges and sizes.

FDM 3D printers have a significant impact on the aerospace industry when a substantial improvement in aircraft performance can justify the cost of highly complex one-off components: the average corporate aircraft travel 75,000 miles per month, and a single component that was designed and manufactured with 3D printing reduces air drag by 2.1%, reducing fuel costs by 5.41%! Small adjustments, like this example, hugely affect life.

On the other hand, the automotive industry is amongst the biggest there is, and the need to create parts that are stronger and lighter is in high demand. FDM 3D printers have great power and enable the achievement of effects that would not be possible with traditional manufacturing methods. Car components produced with the FDM 3D machines are lighter, which results in a reduction of the vehicle weight, better performance, and lower energy consumption.

Focusing on the dominance of 3D printers in both industries, massive improvements in design, validation, production, and customization have been recorded all round. Note that FDM 3D printers’ impact in the aerospace and automotive industry doesn’t just revolve around the research and development phase—designs and patterns created using FDM 3D printers stand as the bedrock powering the day to day innovations of the aerospace and automotive industry.

How to Choose Suitable FDM Printer for Your Industry

By now, we believe you are already heavily loaded. We started by stating how FDM 3D printers work, then went on to the design and principles of some of the fastest FDM 3D printers in the market, hinted out a few benefits users can get from purchasing any of our FDM 3D printers, analyzed the diverse application field and now, we are about to proffer reputable solutions as to how you can choose the best FDM printer for all your industrial needs.

Choosing an FDM printer is not a complex or complicated venture. There is no denying that most prominent FDM 3D printers require an investment well above the $1000 benchmark. No individual would fancy investing such a huge sum with little to no prior assurance that the machine in question would be able to cater to their everyday printing task.

With the idea behind this buying guide being to help professionals and hobbyist stay on top of market trends in terms of the best FDM 3D printer for business and also partake in the lucrative rewards 3D printing is poised to bring, we have stated the basic factors that can influence your buying decision—breaking them down with simple, self-explanatory terms.

So, whether you are looking for a silent printing machine that can print large volumes at once or a bespoke machine with a dual extruder, below are the factors to consider when scouting the limitless FDM 3D printer catalogs available online.

3.1, Your Application Industry

First things first, which industry are you operating from? This might seem like an obvious question, but it’s amongst the few a lot of experts and professionals fail to consider when picking an FDM 3D printer. Your application industry determines almost everything; from how fast the FDM machine needs to be to the design and framework, your application industry determines it all.

Now, while most 3D printers are built to serve individuals in dynamic industries, the operation sequence, resolution, and the result of numerous variants of FDM printers are different. To navigate your application industry, there are a few factors you need to put into consideration.

Am I into 3D Printing for Fun, or I am Professional: 3D printing can be termed an easy and less stressful task when the primary motive behind every print is geared towards personal gain or experience. But when you have a customer base looking up to you for formidable printing solutions, it’s quite different.

When trying to choose an FDM 3D printer, to navigate your application industry, thoroughly analyze the reason behind purchase; are you trying to serve a specific market, or you need an FDM 3D printer to cater to the day-to-day jewelry modeling task?

My Target Audience: if you have considered your reason for venturing into the field, the next phase is to understand your target audience’s needs and desires. Maybe after much consideration, you found out that your target audience is you—that’s you are looking for an FDM 3D printer to help you cater to small modeling task, then you need not worry much about the design and make of the machine; most FDM printers in our collection would provide you with a printing experience like no other.

But if, after much consideration, you realize you are in search of a machine to cater to the needs of individuals in the jewelry or engineering industry, then you might want to take factors such as the FDM 3D printer’s resolution, print quality, and the type of materials it can print into consideration.

Machine Hardware: if you are a beginner yet to navigate his/her way around dynamic or complex printing situations, you might not understand what it means to consider an FDM 3D printer’s hardware component when making a purchase.

To not bore you with the technical jargon attributed to this step of the process, we recommend you put a call through to our support representative stating the type of FDM 3D printer you require, the application field, and the budget at hand. With this information, you can rest assured that our support team would guide you through your FDM machine buying process.

3.2, Print Size Requirement

Taking out time to read the above section would offer you probable hints that take you a step closer to an FDM 3D printer of choice. However, pinpointing your application field by analyzing what you want to use the machine for, your target audience, and the machine’s hardware is only one phase of the process; the second phase entails navigating your print size requirement.

There are hundreds of FDM 3D printers available, each varying in design, shape, and size. If you have successfully navigated the industry and audience, you want to purchase an FDM 3D printer for, then you have an idea as to how big or how small your day to day print size would be.

The type of model you can create with 3D printers varies based on the machine you are using. Knowing your print size requirement helps break through the noise and serve your customers better.

So, how do you navigate your print size requirement? There are two major actors to consider.

Unit of Measure for Your CAD File: every design or model you make using an FDM printer is subject to the unit of measure in your CAD design. That’s your CAD design determines how big or how small your prints would be, its dimension and design sequence. While it’s impossible to accurately decipher the type of designs your clients would require from you regularly when trying to choose an FDM 3D printer, opting for a machine capable of handling a CAD design with a high unit of measure is essential.

Dimension, Weight, and Size Constraints: the material you chose for your printing task has a lot to say about the printing size. The dimension, weight, and size of the object obtained from a 3D model printed with PLA are quite different from the result you would obtain using an ABS material—regardless of whether the CAD file and design are the same. Considering the type of materials you would print on regularly can help you pinpoint an FDM 3D machine that wouldn’t create constraints in your design’s dimension, weight, and size.

3.3, Printing Material Requirement

Printing material requirements might be the last, but it’s not the least. Printing material is regarded as the last thing to consider when choosing a suitable FDM printer for your industry because its reliability is subject to change. FDM 3D printers are built to create exceptional designs and models on numerous thermoplastic and metal materials.

A typical 3D printing process might sometimes require the user to switch materials during design. This might not be termed the day to day experience of a hobbyist or even a professional in the industry, but in as far as you intend to build a career in the printing industry, it’s an experience you are going to someday have to contend with; why not prepare yourself beforehand? There are multiple FDM 3D printers available, but only a few allow its user to switch back and forth between models and materials.

Tensile strength also plays a vital role in the printing process. Tensile strength, which is regarded as how much pressure a material can withstand before tearing apart, is also a factor to consider when looking for the best FDM machine for your printing needs. Most filaments have unique tensile strength, but when the focus is placed on the overall picture, they are not durable enough to withstand the toughness of most of the FDM 3D printers available.

While there are still factors such as the melting temperature and the material’s durability to consider, their influence on the type of FDM printer to choose is not as consequential as the above listed. It’s practically impossible to consider all the material you might ever have to print on using the FDM 3D printer you are about to purchase, but that does not in any way means neglecting the influence of your printing material on your buying decision is probable.

3D printing can be fun and exciting and at the same time daunting and tiring; it all depends on how much time you invest in making the right buying decision. FDM 3D printers are durable modeling machines, but if due precaution is not taken during purchase, you might end up with a printer that keeps your print failing for one reason or another.

If you are looking to avoid the frustration and repetitive sequence that comes with using the wrong FDM printer, we recommend you contact our support team; whether you need a cheap FDM printer, professional FDM printer, or an industrial FDM printer, Dreambot3D got you covered.

FDM 3D Printer Buying Guide

Chapter 3 covered everything you need to consider when choosing an FDM 3D printer for your industry. Detailed info on the application industry, print size, and printing material would certainly take you a step closer to the desired FDM printer, but don’t for a moment think that with just that information, you can acquire a formidable printing machine to cater to your printing needs.

We have been saying it and wouldn’t mind saying it again, FDM 3D printers are high-value purchases. These printers might not be as expensive as LCD or DLP, but that doesn’t mean you wouldn’t have to spend a considerable sum purchasing a professional FDM 3D printer for the job. To ensure that you are making smart buying decisions, we have listed the basic factors to consider before making a purchase.

Note that you might not be able to put every factor listed out into account when purchasing an FDM printer—you don’t have to beat yourself up for that. However, we recommend you try as much as possible to consider most of the factors listed out below before settling for any 3D printer.

4.1, Choose a Reliable Brand

There is Apple, and there is Samsung—two formidable brands. In the smartphone market, one possesses a higher rating than the other; why is that? Everyone likes having an affiliation or something to do with the best. In the smartphone market, Apple is regarded as the best, so it’s no surprise that most people opt for its product over Samsung.

Now to FDM 3D printers, there are hundreds of products built and designed by different brands. Most of these printers can boast of the basic FDM 3D printing features, operate at a fast speed, and give you the exceptional output you desire, but shouldn’t be considered a prioritized pick; why do we say so?

Making a high-value purchase requires prior information about the brand you want to purchase from. Settling for any brand doesn’t only mean risking funds on an investment that might prove unproductive halfway down the line but also jeopardizes the integrity of your modeling process.

Purchasing an FDM 3D printer from a brand that doesn’t have a track record of reliability backed by authentic customer feedbacks can leave you with printers that don’t automatically suspend printing when filament runs out or break, causing you more harm than good.

We know that there are many FDM 3D companies out there, and finding one that is sophisticated enough to give you the printing experience you desire can keep you scouring the internet for hours. To save you this stress, we operate with a team of highly-detailed support services ever ready to help guide your buying decision in terms of brand efficiency and product durability—place a call today.

4.2, Safety Configuration of the Machine

The constant plea of safety first can seem inconsequential when an FDM 3D printer offering formidable features is thrown your way at a discounted price. The idea behind FDM printers is to provide a safe printing experience and, at the same time, help users save filament and time. LCD and DLP printers are comparable to FDM in terms of durability and printing accuracy, but in terms of safety and out of the box usage, FDM printers are miles ahead.

In simple terms, backing your purchase up with detailed information on the precautionary measures and built-in safety designs accessible via an FDM 3D printer of choice is paramount. We believe that professionals or hobbyists who have been in the industry for a long time would understand why we took our time to emphasize the machine’s safety configuration.

However, suppose you are a newbie trying to navigate rocky paths with an FDM 3D printer optimized with formidable advantages. In that case, we recommend you don’t allow features such as the stable default settings or the printer’s ability to keep your printing model in a perfect state make you go head over heels and forget to analyze the safety configuration of the machine.

FDM printers cannot be termed user-friendly in scenarios where issues arise during the printing process. To be on the safe side, don’t finalize your purchase without carrying out a thorough analysis of the printer’s safety configuration. If you are new to the industry and cannot navigate your way around the safety configurations, don’t hold back your questions; feel free to ask as many questions as you deem probable before paying a penny.

4.3, Resolution Requirement of the Machine

While the resolution requirement of an FDM 3D printer is regarded as the number one factor to consider when making a 3D printer purchase by experts in numerous industries, this can be referred to as a myth that doesn’t apply to all. The resolution of an FDM printer determines the clarity and precision that can be enjoyed from a given 3D model and pattern.

However, the resolution of an FDM 3D printer used in the animation industry doesn’t have to be on the same level as the one used in the jewelry or engineering industry. When looking at the resolution requirement of an FDM 3D printer, it’s important you take into consideration the industry you are operating in. In which industry do you want to use the machine? What sort of models do you want to print? How clear or precise does the model have to be for it to be termed efficient?

Answering the above-listed questions would help you demystify some of the myths attached to buying a 3D printer. Yeah, buying a high-resolution FDM 3D printer should be considered a priority if the funds and budget to finance it is available. But in scenarios where you are on a budget, you can save cost by analyzing the machine usage and model requirement.

FDM 3D printers come in different variants, shapes, and sizes, optimized with a fitting design and resolution. At Dreambot, our daily task revolves around catering to individuals’ dynamic needs and desires from numerous parts of the globe. We know how daunting navigating a machine with a proper resolution can be.

Dreambot’s core value is to provide satisfactory all-round services. To keep up with this mission, we offer a support team that can help you understand the resolution requirements of multiple machines, the industries they are optimized to serve, and direct you towards multiple variants that would serve you better.

4.4, Consider Weather, the Price of the Machine, is Acceptable

Many folks believe that the price and budget should be the first consideration when purchasing an FDM 3D printer. While there is little room to say otherwise, at Dreambot’s, we beg to differ. The price of an FDM printer plays a major role in the buying process, but not in comparison with the machine’s resolution requirement, brand, and safety configuration.

The price tag attributed to a machine is dependent on numerous factors. It’s a widely accepted notion that machines with higher price tags usually possess formidable features not accessible or found in machines with lower prices. This might be true, but not at all times. There are many FDM 3D printers with budget-friendly price tags and more stable features than their counterparts.

Pricing nowadays relies on the perceived brand value; that’s the brand’s track record and how customers regularly interact with their goods. Now to know if an FDM printer’s price is acceptable, you must first consider the basic requirements listed above {keep in mind that personal preference and features should also be considered when estimating an FDM 3D printer’s price tag}.

If the design and features the FDM 3D printer possesses are in line with your business goals and that of your clients, then it’s okay to deem the price tag acceptable. Never settle for an FDM machine based on its expensive or cheap nature. The belief that cheap FDM machines are prone to spoilage is false; the price of FDM 3D printers depends on the machine’s brand and quality. To get a professional FDM 3D printer at an affordable price, endeavor to evaluate the features and benefits you require from the machine.

4.5, Consider the Suppliers After-Sales Service Capability

Making a purchase is one thing; enjoying the benefit of your purchase to the fullest is another. The best FDM 3D printer always requires a sizable investment, and we are certain you wouldn’t want to make such an investment from a supplier with little to no track record of authenticity or credibility in the industry.

To avoid making such a mistake, take into consideration the technical support service offered. Every FDM 3D printer supplier should provide a minimum of 12 hours of technical support service Monday to Friday. However, there are a lot of reputable companies providing 24 hours technical support 365 days a year.

Vetting the technical sales service’s credibility would help you better understand the type of after-sales service, an FDM 3D printer manufacturer offers. Bear in mind that it’s practically impossible to authenticate the viability of a brand’s after sales service directly from the company. The fastest way to get ahold of such information is by contacting individuals who have done business with the brand before.

Like always, Dreambot is here to serve you better. Our technical support service is available on around the clock basis. Whether you have made up your mind about the machine you want to purchase or are still scouring our catalog for the best FDM 3D printer to cater to your printing needs, our support service is just a call away.

Why Our FDM 3D Printer is One of the Best Choices

If you have been reading along, you might want to take a trip down memory lane back to section 1.3, where we highlighted some of the features that make Dreambot’s FDM 3D printer a superior choice. Stating the benefits our FDM printing machines bring to the global market might have sparked an interest to explore our catalog but didn’t eliminate skepticism to check out other brands.

At Dreambot, we have experienced the repercussion of leaving the smallest of details to chance. Since we are not eager to explore such experiences again, we think it’s important we highlight some of the factors that make our FDM 3D printers a reputable choice amongst other brands.

Chassis with an Overall Stable Structure

At Dreambot, we know what’s it like to have to pause a printing process because of an FDM 3D printer with a supporting frame that’s not stable. Exceptional design and innovation that enhances our clients’ experience is core to the operations of Our R&D team.

To ensure that our clients are not left hanging at any point of the printing process, we didn’t opt for the regular simple structure, acrylic metal box design used by most manufacturers.

Our FDM 3D printers are optimized with enclosed chassis. These integral sheet metal chassis help guarantee stability of the overall structure. That’s when using any of our FDM machines; you get to enjoy a smooth, stable, and accurate process even when operating at maximum speed.

Constant Temperature System

Prior experience in the printing line would have given you insight that there are lots of filament and other printing materials that are heat resistant. Using such material to print can result to a prolonged printing process.

To counter this issue, all our FDM 3D printers are optimized with a constant temperature system. This system heats the entire printing control of the chassis to a high-temperature state so that heat resistant materials will not be warped and drawn when printed.

Compared with most other FDM printers available globally, the constant temperature system our machines are equipped with makes it a high-cost performance machine capable of tackling complex printing procedures within a short period.

Large Screen

The relatively small screen displays of most FDM 3D printers make operating the machine a pain in the ass. Most manufacturers pride themselves around FDM 3D printers with a small 5-inch interactive screen not flexible enough to touch nor bold enough to read.

At Dreambot’s, keeping our clients one step ahead of the competition is the ideal operation mode. Our FDM 3D printers are equipped with a large 7-inch color screen and various languages to help users from different parts of the world enjoy a simple yet detailed printing process.

Simple to Use

If you explore this buying guide in full, you will notice that we generously used the term, out of the box operation. That’s you don’t have to tie or fix anything after purchase. Our machines come packed with all the upgrades you need already built-in—you don’t have to lose a screw or fix complex parts.

Unlike most other FDM 3D printers, our FDM machine is built with a relatively simple operating system. With a Dreambot FDM machine at your disposal, a right out of the box printing process is guaranteed.

Stable Market with Complete Range of Sizes

What sort of FDM printing machine are you in search of? Do you need a printer to handle large dynamic models or something small to carry out your day to day printing task? Regardless of the type of FDM 3D printer you are looking for, Dreambot got you covered.

We offer a large size selection with the entire series. Unlike most manufacturers that can boast of only one or two regular sizes and in most cases require extra funds for the others to be customized, Dreambot boasts of a collection that can power a stable market with a complete range of sizes available all year round.

Industrial Grade Machines

Dreambot has been tending to individuals’ dynamic needs from different parts of the world for the past eight years. And unlike most other manufacturers dealing in the production and distribution of FDM 3D printers, our catalog comprises mainly of industrial-grade large machines with rich production capacity. Note that we don’t make desktop-level machines.

If you need an FDM 3D printer built by individuals with strong R&D capability and experience, sustainable OEM, and spot capabilities, then please don’t hesitate to get in touch.

Finally

FDM 3D printers are making waves all over the globe. From education to finance, engineering to automotive, these 3D printers are proffering leading solutions. The FDM 3D market is already crowded with hundreds of manufacturers priding themselves with the authenticity and credibility badge, but very few suppliers who understand the dos and don’ts of the industry.

This buying guide was built to help you make the right buying decision, and if you stayed with us throughout the journey, we are certain you are well equipped with all the info you need to navigate the best FDM 3D printer for home or business needs.

However, if you still require assistance pinpointing the fastest FDM 3D printer for your business/industry or you need an FDM 3D printer manufacturer that can get an industrial-grade FDM machine to your doorstep within 3 to 5 business days; don’t hesitate to place a call today—Dreambot’s support team operates around the clock, ever-ready to cater to your printing needs.

FAQ Guide

What does FDM Mean in 3D Printing?

FDM means Fused deposition modeling. FDM is regarded as a 3D printing technology often used to print 3D models and patterns. FDM machines can be found in almost every industry. The 3D printers are renowned for their ability to create 3D models of high quality with high accuracy and durability at cost-efficient rates.

How does the FDM 3D Printer work?

For an FDM machine to function properly, it requires a heated nozzle, a build platform, and raw material to build upon. The printing process begins after the modeling software slices the 3D CAD file creating an extrusion path for the nozzle to follow. The object’s necessary support is factored into the extrusion path, and the nozzle movement is controlled via the interactive interface found on the machine. When the software successfully determines a suitable path for the nozzle, the filament is let loosed and fed through the heated nozzle. As soon as the raw material gets to the nozzle, it dissolves to a semi-liquid state and is forced out of the nozzle in the form of super fine beads. Immediately after the material leaves the nozzle, it hardens and bonds to the layer under it. Using the FDM machine Mcomputerized interface, you can lower the platform holding the material to about one-sixteenth of an inch, giving room for the nozzle to start working on the next layer. Note that to remove the object or model created from the platform, you have to either break them off or use a solution of detergent and water.

What are the Advantages of FDM?

FDM 3D printers possess lots of advantages. Listing out all the advantages can keep you reading this piece for hours. To save time, refer back to section 1.3 of this buying guide. However, below are some of the rare advantages you enjoy from purchasing an FDM 3D printer.

Air filtration:

American scholars have researched that long-term 3D printing will create harmful gases. FDM 3D printers are equipped with air filters that keep the environment clean and odorless. FDM 3D printers create more high-end products for you wholeheartedly.

Material alarm:

FDM 3D printers are optimized to pause and check if you want to replenish the material thread during printing, pause and notify you, then allow you to add more materials before it resumes printing. The result is that even if the materials are used up, you can still complete the printing. More successful printing means a higher return on investment and higher efficiency.

Enhanced first layer adhesion:

A high-quality 3D printed part is built on a good first layer. FDM printers leave room for a level platform and compensate for any small changes in its surface by adjusting the Z-axis height in the printer’s first layer to ensure that the printing is perfect to go again.

Improve the printing environment:

The glass door helps control the airflow inside the printer, helping users obtain better printing quality, reliability, and higher security. FDM 3D printer’s anodized aluminum template provides a more reliable printing experience for engineering materials. It provides a more consistent surface finish with well detailed and accurate prints.

What Should I Know Before Buying a 3D Printer?

There are a lot of factors to put into consideration when looking to purchase a 3D printer. We covered most of the basic factors in chapters 3 and 4 of our FDM 3D printer buying guide. However, to give you an idea of what is contained in the text, we have listed some of the basic factors that must be considered when buying a 3D printer.

- Your application industry

- The 3D Printer manufacturer/brand

- Safety configuration of the machine

- Resolution requirement of the machine

- Price of the machine

- Suppliers after-sales service

What is the Difference Between FFF and FDM?

There is no much difference between FFF and FDM. FFF stands for Fused Filament Fabrication and goes by a printing process that involves building an object by depositing melted material layer by layer, same as Fused Deposition Modelling FDM. The only thing differentiating the two terms is the historical background. The layer-by-layer 3D printing process was first regarded as FFF until Stratasys {a leading company in 3D printing and development} trademarked the FDM term in 1989.

Which is Better, TDM, or FDM?

TDM and FDM are both regarded as multiplexing techniques. While FDM circuit orientations make use of analog signals, TDM makes use of both analog and digital signals. In comparison, TDM serves as a better multiplexing technique than FDM. TDM is comparatively cheaper, less prone to interference is highly efficient.

Do FDM Printers Smell?

FDM printers left on their own do not smell, but when used to create patterns or models in an environment not well ventilated, issues or irritation can occur. FDM printers make use of resins, which naturally give off fumes. Particles emitted from consumer-grade FDM 3D printers could negatively impact indoor air quality. To avoid such issues, it’s important you make use of your printer in a well-ventilated environment.

How Do FDM 3D Printers Work?

Fused deposition Modelling {FDM} printers or Fused Filament Fabrication {FFF} printers {as they were formally known till the FDM term was trademarked by Stratasys in 1991; the company behinds its first design} are machines built to deposit melted material in a pre-determined path layer-by-layer selectively. Fused Deposition Modelling {FDM} printers are 3D printing machines that create images one at a time. FDM printing process revolves around a three-dimensional output. Each layer of the material you are printing is placed on top of another again and again till a finished product is acquired. The printing process begins after the modeling software slices the 3D CAD file creating an extrusion path for the nozzle to follow. All necessary support needed by the object is factored into the extrusion path, and the nozzle movement is controlled via the interactive interface found on the machine.

Is FDM Safe?

Yes, FDM 3D printers proffer a safe and efficient printing process. You don’t have to worry about toxic fumes or a complicated printing process when using an FDM machine. However, it is important to note that the safety and efficiency of your 3D printer is dependent on the manufacturers or brand machine you are making use of. To be on the safe end, endeavor to opt for FDM 3D printers with an anodized aluminum template—machines with this feature are deemed more environmentally friendly and safer for use than most other variants.

What is FDM Used For?

FDM printing is a commonly used additive manufacturing processes for fabricating prototypes and functional parts with common engineering plastics. These machines are used to design 3D models and patterns used in the research and development phase of numerous products in multiple industries. FDM printers have built a sustainable reputation in the automotive, medicine, engineering, electronic, and education industry.

Why are Guard Bands Used in FDM?

Guard bands are used to avoid interference between two successive channels. If you are familiar with the FDM printing process, then you must have noticed that several signals are sent simultaneously on the same ME allocating a separate frequency band or channel to each signal. To ensure that issues of interference don’t occur, guard bands are used.

What is the Main Use of 3D Printing?

3D printing is an additive manufacturing method commonly used to produce functional shapes by individuals looking to use less materials, save more time, and enjoy the smooth and efficient modeling process traditional manufacturing methods cannot offer. 3D printers create three-dimensional components from CAD models. 3D printers allow users to design their own creations easily and give them the confidence to try out new models.

Is Rapid Prototyping the Same as 3D Printing?

On the same plane, rapid prototyping and 3D printing are both product development methods used in additive manufacturing. Both product development methods create models layer by layer using CAD data. 3D printing is a manufacturing process that takes a digital 3D model and turns it into a physical object. In this process, a material is fabricated using a print head, nozzle, or other printing technology, while Rapid Prototyping or RP is an application used in additive manufacturing to create a model faster than the normal process. Rapid prototyping is mainly completed using 3D printing or additive manufacturing technology. Both perform the same function but in different fields/industries. However, Rapid prototyping and 3D printing vary largely in terms of price, complexity, material choices, and accuracy level.

What is the Example of Additive Manufacturing?

Additive manufacturing is all about building an object, pattern, or model layer by layer. The beauty of its design revolves around its simple yet detailed process. For example, instead of milling a workpiece from a solid block, additive manufacturing builds the part up layer by layer from material supplied as a fine powder. Various metals, plastics, and composite materials can be used. Additive manufacturing is relevant in many areas and for numerous industries.

What are the Benefits of Additive Manufacturing?

Additive manufacturing simplifies the printing process to an extent where even the average joey can enjoy an out of the box printing experience. Additive manufacturing aids users in printing assemblies as a single piece. That’s you get to save money from every printing process. Additive manufacturing also gives users the opportunity of printing multiple movable parts as a single piece. Compared to other conventional manufacturing processes, additive manufacturing helps you enjoy a simplified yet highly accurate printing process.

Will Additive Manufacturing Replace Conventional Manufacturing?

While additive manufacturing comes with many perks—faster printing time, cost-efficient, simplified printing method, etc.—most experts do not agree that it will replace conventional manufacturing methods altogether. Additive manufacturing enhances countless printing processes, but the materials it can process are quite limited. No, additive manufacturing will not replace conventional manufacturing methods altogether.

How Can 3D printing be used in manufacturing?

3D printing produces objects following a 3D digital model. The manufacturing industry revolves around product prototyping and design. With an FDM 3D printer, experts in the manufacturing industry can simplify the complex syntax and operations attributed to the process. By using a 3D printer and adding material layer by layers, such as plastics and metals, complex objects can be produced both rapidly and at low cost, in short runs, or as one-of-a-kind parts.

Is 3D Printing Commercially Viable?

The 3D printing industry is estimated to be worth over $42 billion come 2025. As to whether the industry is commercially viable, the figures are self-explanatory. However, individuals looking to make a living from the opportunities 3D printing opens up have to consider numerous factors. Amongst the many factors, the type of 3D machine, your industry, and the client base you want to serve take precedence in determining the income your exploits and industry would generate. 3D printing process is taking over R&D in most industries. At its current pace, 3D printing is eventually going to eradicate other manufacturing processes utilizing the same materials and operational sequence. With all factors duly considered, we can boldly tell you that 3D printing is commercially viable and there is no better time than now to venture into the industry.