3D Printing Resin Supplier

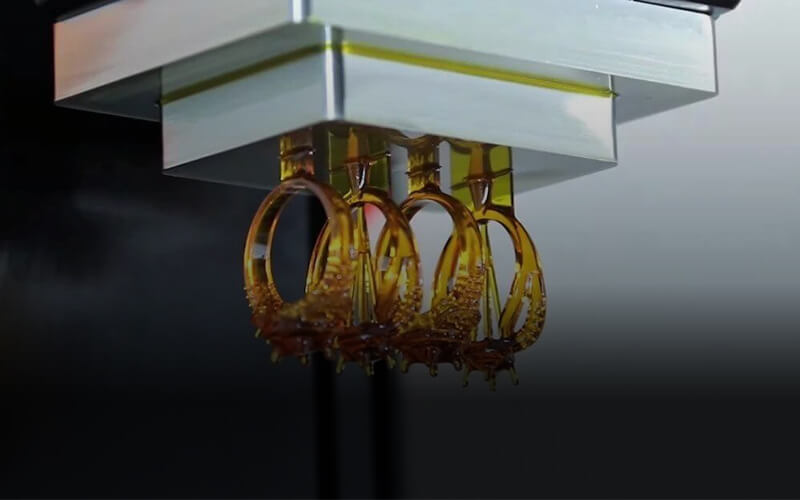

Dreambot3D is a 3D printing resin supplier that produces resins that use the LCD technology which solidifies UV resin to create high quality 3D objects at a fast rate.

Resin 3D printing is an additive manufacturing technology that cures liquid photopolymers layer by layer into a solid object.

We are 3D printing resin supplier for industries such as jewelry making, dental, animation and props, miniatures industries, etc.

3D Printing Resin

Dreambot3d is a 3D printing resin supplier that produces resin materials that provide high quality and highly detailed, smooth results compared to other 3D printing materials. We are a 3D printing resin supplier that manufactures and distributes 3D printer resin and materials like high temperature resin, castable resin, flexible printer resin, etc.

Resin reacts under ultraviolet light or laser beam energy that changes the state from liquid to a solid structure, layer by layer. We are a 3D printing resin supplier for professionals in jewelry making, automotive parts, medical industries and hobbyists. All 3D printed objects using the resin material are high quality and detailed.

Application of 3D Print resins

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

What Our Customers Say

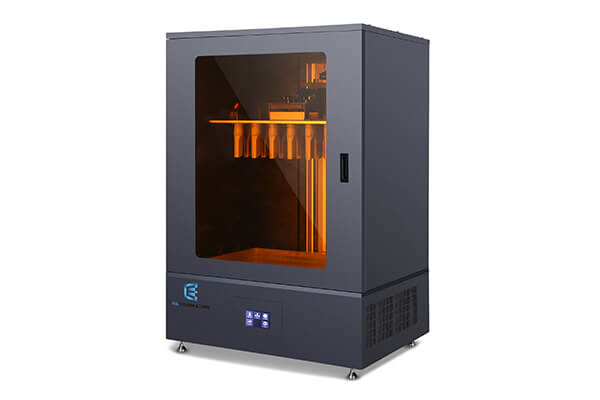

Dreambot3D Resin 3D printers for your choice

ME-192 LCD 3D Printer

The ME-192 is prints at 192*120*270mm suitable for small scale and personalized 3D printing. The printing speed for all applications is 40nm/h.

DB-345 LCD 3D Printer

The DB-345 has a maximum printing size of 345*192*335mm for jewelry mold making and other applications. The printing speed is 20nm/h.

LG-550 LCD 3D Printer

The LG-550 printer is an industrial sized printer with a printing volume of 527*296*550mm. The printing speed is 20nm/h and a curing wavelength of 402-405nm.

buying guide of 3D Printing Resin

With time, 3D printing has become very common, and the technology has now reached a point where you can choose between different types of 3D printing technologies. There is no doubt that FDM or filament-based 3D printing is dominating the overall 3D printing market.

However, the resin-based DLP or LCD 3D printing method is also getting popular in different industries. It can be said that 3D resin printing has advanced enough to cover different requirements of the users, both for 3D printing different specialized products, resistant parts, decorative pieces, and more. But don’t forget to buy the best quality resin from a reputed 3D printing resin supplier for better results. Now, let’s discuss about the resins.

What do you mean by resins?

Resin 3D printing material can include highly viscous and solid materials. However, it commonly refers to liquids material that hardens when it comes into contact with light, incredibly UV light. In general, synthetic or modified resins are widely used in the manufacturing process.

These materials can be made of different natural components along with different artificial polymers and additives. The products made of resins can be very durable and sustain heavy pressure and scratches.

Different properties of resin in various product variants

- Maximum layer thickness that can be applied

- Flowability or viscosity

- Adhesion properties

- Curing process duration

- Degree of hardness

This article will get to know about how resin-based 3D printing works and the different types of resins that you can buy. Besides, we have listed down some valuable tips going through which you can choose the best 3D printing resin for your project. So, keep reading.

What do you mean by resin-based 3D printing?

As the name suggests, resin 3D printing utilizes plastic resin, different from filaments that are used in FDM 3D printing. Speaking more about this, the resin may include the composition of epoxy, or sometimes it can combine methacrylic and acrylic monomers. These monomers, when exposed to a light source (UV light), create molecular bonds and become solid. This is the process that LCD 3D printers use.

Resin 3D printing is like FDM 3D printing, and the 3D objects are made by the layer-by-layer building process. Under this one-layer, molecular bonds with another layer are created, thereby forming a strong adhesion. The process repeats until the completion of the model.

In the 3D printing industry, you will find different technologies that work on resin-based 3D printing. These are DLP- Digital Light Processing, SLA- Stereolithography, and LCD- Liquid Crystal Display 3D printing methods. Among these, the most popular one is LCD 3D printing. This technology relies on a controlled emission of UV rays on the tank of liquid resin, converting the solid polymer into solid based on the pre-defined model.

The products made using printer 3D resin will need some amount of post-printing curing to attain maximum durability. This can be carried out using a UV curing chamber or by placing the models under sunlight.

Some benefits of 3D printing using resins?

Consider garbage bins kept outside the house and the level of abuse the bin takes from different items filling them, moving around, and even vehicles hitting the bin. It may absorb the impacts and bend, but it doesn’t break. Well, from this example, you may have got a clear idea about the durability and strength of a resin-made product. Now, let’s talk about some other benefits.

Higher level of resolution and accuracy

One of the primary reasons you should use resin instead of filaments is that resin printing looks better if opted. In the case of an FDM 3D printer, the resolution will be limited by the nozzle size that extrudes the melted filaments. However, in the case of resin-based 3D printing, the resolution will be limited by the size of the laser being projected into the resin.

As a result, resin 3D-printed models will have super fine details. Besides, the 3D-printed model will come with a satisfyingly smooth finish. This is not possible if you are using an FDM 3D printer even though you are using the same post-processing method.

There is no doubt that modern FDM printing technology is making a huge stride. You can even go for a 10-micron FDM 3D printer. But it can be said that resin-based printers such as the LCD 3D printers can concede the advantage.

Perfect for engineering and mechanical applications

Some people assume that FDM 3D-printed parts are more robust and sturdier than resin 3D-printed parts. But the truth is both the printing type can offer an impressive level of lateral strength. In fact, the strength of the object will not change with the orientation.

So, resin 3D printing can be a perfect choice for applications where the properties of the materials matter. What’s more? Resin 3D printing can be used for faster complex assemblies of individual parts, and you can create intricate designs. As a result, you can easily print different functional prototypes as well as models for the manufacturing and engineering industry photosensitive resin.

Faster 3D printing

It has been proved that the resin 3D printing process is much faster than filament printing. In the case of an FDM 3D printer, the printer’s extruder moves around the printing platform to apply melted filaments as per the design.

This process is a little slow as the weight of the extruder as well as the controlled way in which the melted filament needs to be extruded. But in resin 3D printers, you won’t face such issues. In resin printing, the entire object design is flashed on the resin with pre-defined patterns.

Robust and durable finished products

One of the significant weaknesses in FDM 3D printing is that the finished products will demonstrate strong anisotropy. In general, a filament-made model can be fragile against shear stresses. The adhesion may not come out good. In resin 3D printing, the UV curing process produces a stronger layer-to-layer adhesion. As a result, the finished product will have better mechanical properties. The parts can sustain heavyweight and pressure.

Excellent level of water tightness

A 3D-printed model may look waterproof, but a tiny gap between the layers can lead to water leakage. Besides, some filaments may dissolve when they come into contact with water or other liquids. But resin 3D printing can be a perfect solution as resin printer resin supports impressive water tightness properties. The printers produce sealed layers with 100 percent accurate dimensions.

So, the resin can be a great 3D printing material. Now, let’s talk about different types of resins that you can buy for your resin printing projects.

Common Resin Used in Resin 3D Printer

LCD resin used in the 3D printing industry offers excellent results. These smooth materials generally focus on superb quality and lower cost. Some other important features are easily printable, provide better details, printing larger sizes, and offer an excellent level of transparency. Two significant technologies use for printing resins are SLA- Stereolithography and DLP- Digital Light Processing.

One of the best things about resin 3D printing is you can choose different types of resins based on the type of object you can want to make. Have a look at various types of printer 3D resins that you can use.

1.1, Standard rigid resin

Standard rigid resin, also known as engineering resin, is specially designed to easily withstand the extensive level of testing. The objects made of rigid resin can show better performance under repeated stress. Such resin is popular for its precision as well as stiffness.

In some cases, the rigid resin comes reinforced with glass powder in order to enhance the strength, and you will enjoy a detailed and polished finish after the UV curing process. The material is stable and strong. Some studies have proved that rigid resin 3D prints are resistant to deformation. So, this can be a perfect option for making fixtures, jigs, manifolds, thin-wall parts, and more. The resin can demonstrate a tensile strength of 36 to 52mpa, which is quite impressive.

Why use standard rigid resin?

Engineers and manufacturers should use this resin if they are looking for a material that is impressively strong, stiff, and can produce quality parts with outstanding features and details. These resins can offer an impressive print quality at 40 to 100 micros. With good fluidity, the viscosity level is low, and it produces less odor. You can use this resin to make jewelry models, handmade models, artwork, and DIY.

The mechanical properties

- Applicable wavelength- around 395 to 405 mm

- Bending modulus- 1.882 to 2.mpa

- Bending strength- 59 to 70mpa.

- Deformation temperature- 80-degree C

1.2, ABS resin

If you are looking for an ABS-like material for your LCD 3D printer, you can go for ABS resin. The resin has perfect balance properties of impressive surface finishing, better molding control, metal plating characteristics, and better impact resistance. As one of the best resins, it is widely used for manufacturing electronic or electrical equipment and in the automotive industry. Using ABS resin means there will be a huge volume of printing material that can be recycled. ABS resins can be processed twice without compromising the printing stability. Another best thing about this resin is it has a low shrinkage rate, so the printing size will be accurate. Besides, the tensile strength is around 56 to 72mpa.

This thermoplastic resin guarantees better durability, high rigidity, impressive chemical resistance, and dimensional stability. The outstanding features of ABS resin are the result of its compositions. The durability and strength come from acrylonitrile, and butadiene rubber offers toughness. Well, you can modify the compositions to enhance their toughness, heat, and impact resistance features.

Some impressive features of ABS resin are:

- High tensile strength

- High impact strength

- Excellent ductility

- Extremely touch and rigid

- Electroplatable

- Better dimensional stability

The ABS resin is perfect for small batch parts production, industrial design verification, fixture production, and manual mode production.

The mechanical properties

- Applicable wavelength- 395 to 405mm

- Viscosity level- 200 to 250mm

- Bending strength- 69 to 75mpa.

- Bending modules- 2.882 to 3.835mpa

- Deformation temperature – 80-degree C

1.3, High hardness resin

With the rapid development of the 3D printing industry, the applications possibilities are also increasing, and the type of printing resin that can be used in this industry is getting more abundant. Presently, some industries or manufacturers that require high mechanical strength are using photosensitive resin. However, the performance is not very impressive. The 3D object made of standard resins can be fragile and will come with smaller details. When it comes to prototyping and engineering, the model needs to be very durable. This is where you can use high hardness resins.

Such resins are designed to offer the mechanical properties of ABS, which are very durable. The 3D models produced using high hardness resin can withstand a higher level of strain and stress. Different studies have proved that 3D objects developed by this resin, for instance, carrier gear, will be able to withstand higher impact forces and different mechanical pressures. In fact, some products are also tested using drills. But no breakage was found.

This can be the perfect resin for your 3D printers. Some of the outstanding features of high hardness resins are:

- Best for functional prototypes and mechanical assemblies

- It can be used to produce sturdy and shatter-resistant parts

- Offer adequate resistance to the cyclic loads

- Demonstrates higher shock resistance compared to the standard resins

- It can be used for fixture production and industrial design verification

- Accurate printing size with low shrinkage

The mechanical properties

- Applicable wavelengths – around 395 to 405mm

- Viscosity level – 170 to 210mm

- Modulus of elasticity – 2.882 to 3.735mm

- Tensile strength- 35 to 42mp

- Deformation temperature- 80-degree C

1.4, High toughness resin

The standard photopolymer resins used for resin 3D printing are a little fragile, and sometimes the prints can be susceptible to snapping or cracking. That is why such technologies are generally used for artistic models or visual prototypes. Well, looking at the requirements for the best quality resin that can withstand heavy pressure, some companies have introduced high toughness resin. With time, this resin is getting popular among manufacturers.

This resin can mimic the mechanical properties of ABS material. As per some tests, high and tough printing resin can easily withstand high stress and strain. On the other hand, 3D models printed using this material can offer up to 56 MPa of tensile strength and around 3 GPa of bending modulus.

Some benefits are

- Creates shatter-resistant and sturdy parts

- Perfect for mechanical assemblies and functional prototypes

- Excellent cyclic loads resistance

- Lower shrinkage level and supports accurate printing size

The mechanical properties

- Deformation temperature- 80-degree C

- Tensile strength- 46 to 57Mpa

- Applicable wavelength – 395 to 405mm

- Viscosity – 190 to 230mpa

- Modulus of elasticity- 3.382 to 4.635

1.5, Elastic resin

The modern 3D printing industry has gone through a massive revolution. As a result, the complex designs that were challenging or impossible to make now can be created easily using the resin 3D printer and with elastic or flexible 3D resin. As the name suggests, these resins can be twisted, stretched, and bent, but the models will not lose the original shape. If you are using standard resins to create flexible parts and not getting the desired level of flexibility, then it’s time to use flexible 3d printing resin. Using these resins, you can create rubber-like products, phone cases, gaskets, tires, and more. Not just ergonomic or functional prototypes, it can also be used for making end-use parts.

Elastic resin comes with impressive elastomeric properties. But the level of elongation is quite low. So, the 3D-printed parts will be bendable and compressible. However, they can be stretched to a specific limit.

Application of elastic resin

The unique compression quality of the elastic resin makes it ideal for making objects in high-impact applications. You can use this for ergonomic or functional prototypes. The resin can also be used for making end-use parts.

Some manufacturers use this for producing grips, custom holds, gaskets, wearable prototypes, stamps, cushioning, and more such flexible items. Elastic resin is also utilized for soft-touch materials simulation. Even though you may not attain fine detail with this LCD resin material, this can be used for different purposes. If you are looking for the best quality flexible resin 3D printing material, it’s time to get in touch with Dreambot3D.

The mechanical properties

- Applicable wavelength – 395 to 405mm

- Hardness level – 75.0 ShoreA

- Tensile strength- 47.2KN\m

- Modulus of elasticity – 2.0Mpa

- Viscosity- 980Mpa

1.6, High-temperature press film resin

The high-temperature press film resin can demonstrate around 250-degree C of HDT- Heat Deflection Temperature. Considering such a higher level of temperature, this resin is perfect for creating injection molding tools, casting, handicraft designs, industrial parts design, and more.

The printing process consumes little power, but you need to print with support structures while making objects using high-temperature resins.

Buy from the best resin supplier, and you can get high-quality resin for the best results. The resin is recyclable, environmentally friendly, non-toxic, smokeless, self-extinguishing, and waterproof. You can use this for milli-fluidic devices, encapsulation of cosmetics, kitchen appliances, and more.

The best thing about the resin is the resin supports a short curing time, and there will be no deformation during the printing process. With a higher level of precision, the finished products will come with a smooth surface. Try it out now.

The technical properties

- Deformation temperature- 200-degree C

- Viscosity – 150 to 300Mps

- Tensile strength- 36 to 52Mpa

- Hardness- 83D

- Bending modulus- 1.92 to 2.38Mpa

1.7, Jewelry casting resin

Speaking about jewelry casting resins, these are low-viscosity epoxy resins and consist of two major components. These are the resin and the hardener. When the components are combined, it leads to a chemical reaction, and that hardens the resin.

As a result, you will enjoy the unique features of jewelry casting resin, i.e., a perfect thin consistency. This feature of the resin makes it easily penetrate and fill the minor cavities and gaps. On the other hand, this also influences the curing time, making it a little short. With this, you can create highly specialized products that can be used for specific applications.

As the name suggests, the castable 3D resin is perfect for jewelry model making and jewelry casting. The final products will have exquisite details and super fine surface quality. The shrinkage level is also low.

The technical properties

- Wavelength- 395 to 405mm

- Deformation temperature- 65-degree C

- Tensile strength- 42 to 62mpa

1.8, Dental casting resin

This resin is specially designed for direct casting. When you apply heat, it will evaporate without producing ash. Such resins are very easy to cast with other materials. The resin can be used in cases where achieving exquisite details and fine surface quality is essential.

The combustion performance level is very impressive, and while printing, you may witness little residual with a small group of expansion. However, that will not affect your prints. The precision is high, and the curing time of our dental casting resin is short. The material is very safe to use and doesn’t come with any dangerous monomer or hazardous solvent.

The technical properties

- Deformation temperature- around 75-degree C

- Bending modulus- 1/192 to 2.525mpa

- Tensile strength- 42 to 62mpa

- Bending strength- 49 to 58mpa

1.9, Dental guide resin

The dental guide resin is a 100 percent biocompatible resin and is specially designed to 3D-print dental or surgical guides that can be used for implant surgery use. As the resin supports high precision, it is straightforward to insert drill sleeves after printing. This safe resin can be sterilized utilizing the standard autoclave protocols. When printing, you will not witness any smell. Besides, during molding, there will be no deformation issue. The finished products will have better impact resistance, excellent molding, a good level of flexibility and strength.

The technical properties

- Bending modulus- around 811.088mpa

- Deformation temperature- around 60-degrees C

- Tensile strength- around 42-52mpa

1.10, Special resin for dental mold restoration

With time, the demand for biomedical materials has been increased following the productive and increased interaction of fields of molecular biology and material science. Focus is being given on producing dental materials with lowed PS- Polymerization Shrinkage and a better degree of conversion. So, there is a great demand for special resins. Such resin supports high precision, and the finished products will come with a smooth surface and very clear details. The printing stability rate is also quite impressive. With a good level of fluidity, this resin has a low viscosity.

The technical properties

- Deformation temperature- 78-degree C

- Bending modulus -1.822 to 2.855mpa

- Tensile strength – 38 to 52mpa

Application of 3D printing resin

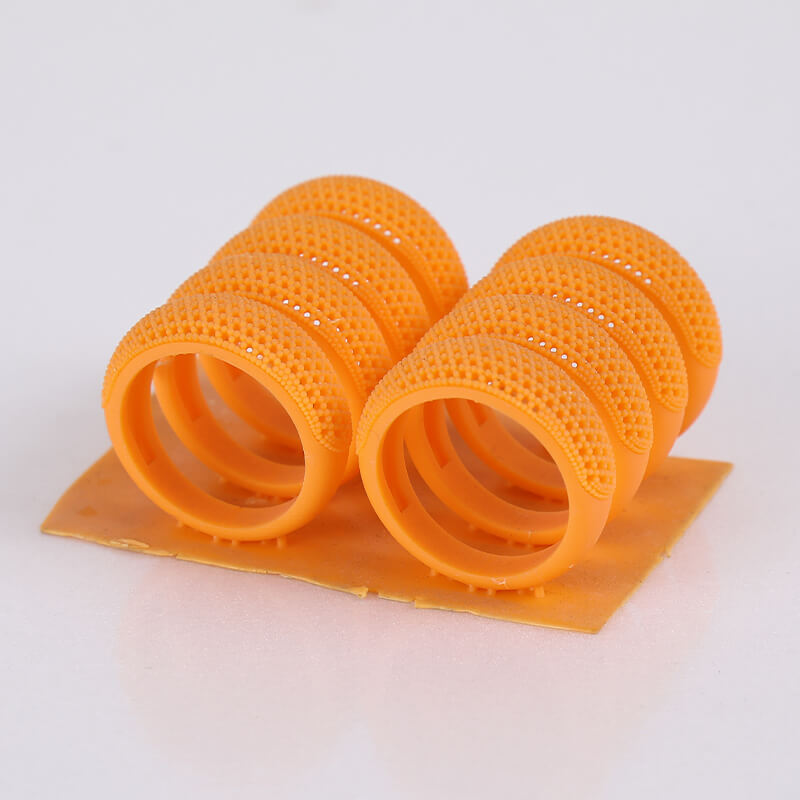

2.1, Jewelry

There are two primary techniques that define jewelry making, i.e., lost wax casting and handcrafting. However, both methods require a significant level of technical expertise and time taking.

Besides, a single mistake can be very expensive. But now, the digital design, 3D printing, and availability of different 3D printing materials have disrupted these age-old practices. The combination has brought huge new possibilities in the design and jewelry-making process. With castable 3D resin and an advanced LCD 3D printer, you can now create new customization options for the customers.

It’s time to witness the power of digital workflows

It has been proved that 3D printed jewelry production has augmented the principles of investment casting, with the advantages of a digital design, castable resins, and a 3D printing manufacturing process.

Speaking about the traditional lost wax casting, designers used to hand-carve the jewelry pattern in wax. After that, the wax is placed in a mold to be burned out. Once done, they pour precious metals such as silver and gold into the cavity to create the pieces. In the end, the designers polish and finish the cast pieces, giving them a shiny appearance.

Now, after the introduction of digital workflow or 3D printing, you can now easily create the design using CAD software tools. A complex design can also be shaped with this. The 3D printer then uses LCD castable resin to produce the 3D printed patterns to be cast in the mold. The entire production process may take a few minutes to get completed, and you don’t even need manual labor for this.

Witness a maximum level of freedom in designing

With this technology, jewelers can produce designs that can be incredibly difficult to hand carve through the traditional manner. A massive breakthrough in castable resins is now setting new standards, letting you witness the best quality product. 3D printing jewelry molds and patterns made using high-quality resins combine the smooth surface finish of SLA-Stereolithography 3D printing technology. You can create delicate filigrees or raised text with impressive sharpness.

What are the benefits of this technology?

Using resins and 3D printing technology is the ideal and most cost-effective way to make 3D-printed jewelry. With this, you can make authentic, solid pieces of jewelry having a smooth surface. Based on the requirements, the pieces can be finished manually through different post-processing methods.

Another significant benefit for the designers is that they don’t have to wait for more about production. Once the digital file is created, a 3D printer will take care of the production process using the resins. With a 3D file, you will get the information that you need to for the 3D printing. All you need to find the best 3D printing resin supplier; buy the resin, and you are all set to go.

Jewelry casting resins- Helping in making better designs.

Thanks to the rapid advancement in 3D printing materials, now you can use jewelry casting resins for jewelry production. Such resins demonstrate an ideal thin consistency required to make jewelry pieces with intricate designs. What’s more? With this resin, you will enjoy a short curing time. The finished products will come with better surface quality and exquisite details. So, go on and buy our jewelry casting resin now to take your jewelry-making process to the next level.

2.2, Dental

Oral surgeons, dentists, and orthodontists are now using 3D printing technology for patient care, testing, and research purposes. Utilizing dental casting resin, it is now possible to make highly exact replicas of any part of the body, including jaw and teeth. With precise replicas, corrective dental implants and appliances can be developed to look, fit and work better.

The 3D printing materials used to make 3D printed models are also enhancing and advancing at a great rate. While most dental objects are printed using filaments, you can now find different types of resins, such as dental guides or dental casting resins. Such materials are widely used in making dental crowns and implants. The process creates the final products that will be indistinguishable from the natural teeth.

Capabilities of dental resins in this industry

The use of resin in the dental industry is growing with time due to the deformation level, hardness, and elasticity level the resins offer. Some major applications are:

- Orthodontic models

The traditional process includes a time-consuming process where the patients have to bite down on gooey so that it can harden into a mold. That will be a model for making treatment for braces or Invisalign or braces. But 3D printing using resins is very different. Using the 3D printing technology, the dentist can now scan the structure and create a perfect mode using a 3D printer and dental casting resin.

- Replacing and repairing the damaged tooth

Using a scanner, you can create a 100 percent accurate 3D image of the teeth and gums. Using that, you can digitally frame the tooth repair and print the model using a 3D printer. The production process will be very fast.

- You can create high-quality surgical tools.

Not just dental implants, using these things, you can easily 3D-print different sizes and types of drill guides, using which you can easily carry out various dental surgical procedures and treatments.

- Create bridges, caps, and dentures

There is a non-toxic resin that can be used to create various types of dental implants. In fact, some resins are also approved by the FDA for such things. When you have the best resins, you can quickly develop a clear aligner according to the teeth structure of the patient. As a result, orthodontic treatments can now be done within a few minutes.

Risk-free dental resins have been used for a few years, and the rapid technological advancement in the market pertaining to the material, curing process, and method of applications are now propelling its popularity in the future. A considerable amount of focus has been given to the filler used for the dental resin to increase the durability and mechanical properties along with impressive polishing and wearability.

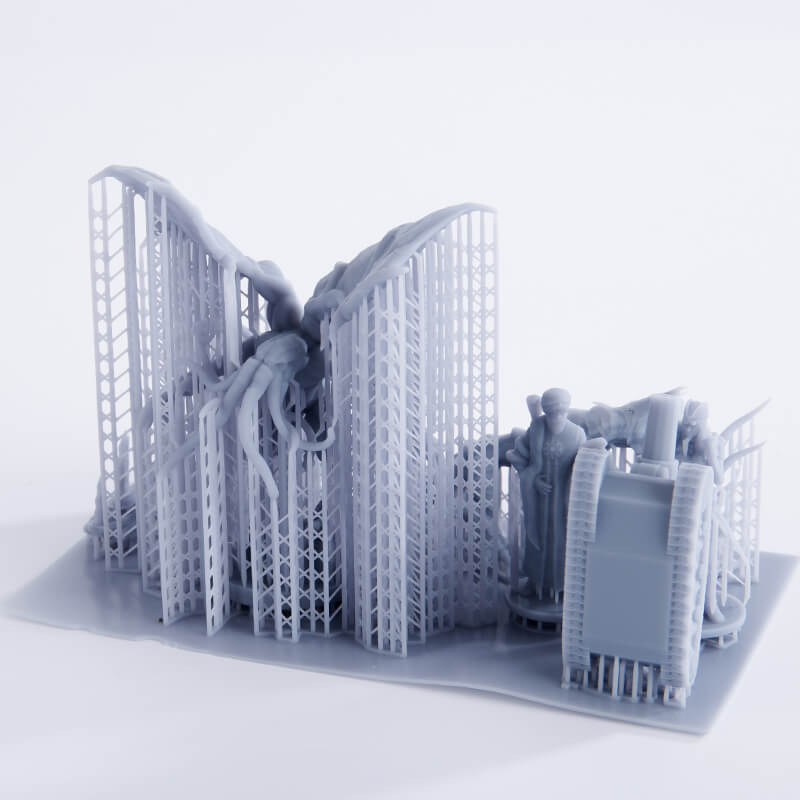

2.3, Anime figure

There is no doubt that hobbyists, as well as individuals, are taking maximum advantage of 3D printing. With the best quality material and 3D printers, you can now create your own customized and designed action figures quite easily and quickly.

3D printers that use resins are used extensively for craft production. Based on your requirements, you can use castable resins, high toughness resin, 3D printer epoxy resin, and more. Use them and manufacture detailed and small figurines.

Improved product quality and fast printing

The objects can be developed from CAD files, a 3D printer, and the best quality resins. Compared to the traditional craft or model-making method, the new technique is quite faster, and the final products will have better quality and details. In fact, with the best printing material, you can now make 5 to 10 small anime figures within a few hours. With this faster production time, manufacturers can enhance their time-to-market. What’s more? You will be able to make a superior product that will instantly attract the viewers’ attention.

With the quality prototypes created by 3D printers using resins, you can make iterations of the prototype every day. In fact, you can test up to 20 new designs every day. Just grab the best printer and the material; you can produce the figures in-house without hiring an expert.

Generally, making a model’s mold using wood or rubber by hand can lead to errors. So for creating a new figure, you will have to make a new mold. This will take a lot of time. On the other hand, for this, you need artistic skills. However, when you use 3D printing technology, you don’t have to worry about these things. With this, the designers can make error-free models every time. Resins are easy to cure and can be customized easily. Compared to the FDM 3D printing, with a resin 3D printer, you can create intricate and small parts with great details.

Forget about any limitation.

Utilizing 3D printer light cured resin, you can create almost everything in different sizes. All you need to get a printer with a good build volume, and you are ready to go. Forget about the complex and challenging mold-making process. Here, all you need to do is feed the design into software, and the machine will carry out the remaining task. The entire anime figure can be created simultaneously with a bigger model. The resin 3D printer can create the parts in batches, and you can combine those parts later to get the complete product.

It is now easy to create a more elaborate figure.

Want to create an anime figure with a maximum level of detail? Don’t worry at all and use castable or our high hardness resins for this. These resins are designed to let you model with fine details with a perfect level of deformation and bendability. No matter how complex the model design is, you can get it done with an LCD 3D printer and the best quality material. The machine will create the models by curing the liquid resins layer by layer, bringing more enhancement to the product’s quality and design.

The material has allowed the professionals to create interlocking parts that can work immediately after the products without going through any post-processing methods. Are you looking for the best 3D printing resin to make high-quality anime figures or 3D-printed superheroes? Don’t look here and there and get in touch with Dreambot3D now.

2.4, Lamp

Resins and filaments are widely used to produces figurines, gadgets, and for crafting purposes. But now, this can also be used in the lamp-making industry. In fact, 3D printed lamps made of molds created from the resin can be more beautiful than the other lamps that are created manually.

Creating custom molds for lamps

With a good quality 3D printer flexible resin, you can easily create various one-off molds for the low-volume manufacturing of lamps. When you have to produce in low volume, this can be very useful. Go for 3D printing and get rid of the hassles as well as costs related to traditional lamp mold making. The modern 3D printing technology has allowed complexity as well as countless iterations on the design.

You can make custom lamp molds and cast using 3D printed objects. Some objects can be used for injection molding as they can sustain a higher level of temperature.

What will be the best resin for this? Well, you can go for high hardness resins. With an ideal combination of strength as well as compliance, such resin can be used to make durable molds to make lamps. The resin can withstand high temperatures and stress. Want to create 3D-printed moonlight? Use this resin for better results.

You can easily craft intricate designs and shapes of lamps within a few hours and attach the LED lights to complete the product. It will look amazing. Why use those outdated lamps when you can now create customized lamps at home using 3D printing technology!

2.5, Crafts

With countless possibilities offered by modern 3D printing materials and technology to artists as well as designers across the world, one can easily craft unique models with various intricate shapes. With the introduction of 3D printing, making a stunning masterpiece or craft will not be repeated. You might be wondering how? Well, you can just save the design file and use that later whenever you need it. Furthermore, 3D printing has enabled artists or individuals to create parts and modify and update them without spending more money.

However, to enjoy the best result with an advanced 3D printer, you will also need good quality printing material. This is where you can trust Dreambot3D. We are here to offer endless possibilities and freedom to for turning your unique imagination and creativity into a physical form. Let’s have a look at the opportunities offered by this technology.

Craft masterpieces and intricate art forms

Making complex parts has now become very easier than before. Utilizing the digital fabrication process, you can turn your imagination into reality with a few simple clicks. It will only take a few minutes to complete the craft with a superior level of curing speed.

It is now easy to restore and preserve exclusive works and artifacts

3D Printing is widely used in different applications like in the field of artifact restoration, creation, and in the fields of archaeology. With modern 3D printing technology, sculptors and artists can easily create the design mesh, which can be used to preserve the design data for later. The artists can easily reproduce work infinitely with the help of 3D printing. Well, it can be said that there will be no one-of-a-kind piece.

Resins- Perfect for making innovative fashion wear and accessories

Gone are those days when artists used to utilize the same outdated designs, and some manufacturing issues limited them. There is no need to produce in large quantities and suffer from a huge loss if there is a tiny mistake. With 3D printing, you can easily craft stunning designs and innovative accessories in no time. What is the best part? Well, there is no need to worry about the inventory.

A great level of freedom in materials, quantities, and sizes

3D Printing lets you choose the size, production sizes, and types of materials. Don’t just stick with the standard resins. Go for castable 3D resin, high hardness resins, flexible resins, and more. One single part can be produced at a very low cost. There will be no restriction on mold or final product size.

Want to create customized, unique crafts or toys? Don’t worry at all and take the help of modern 3D printing technology. With the rapid advancement in 3D printing materials, like filaments and resins, creating a durable model with fine details is not a big thing. So, what are you waiting for? Deploy the technology now in your business and witness the changes.

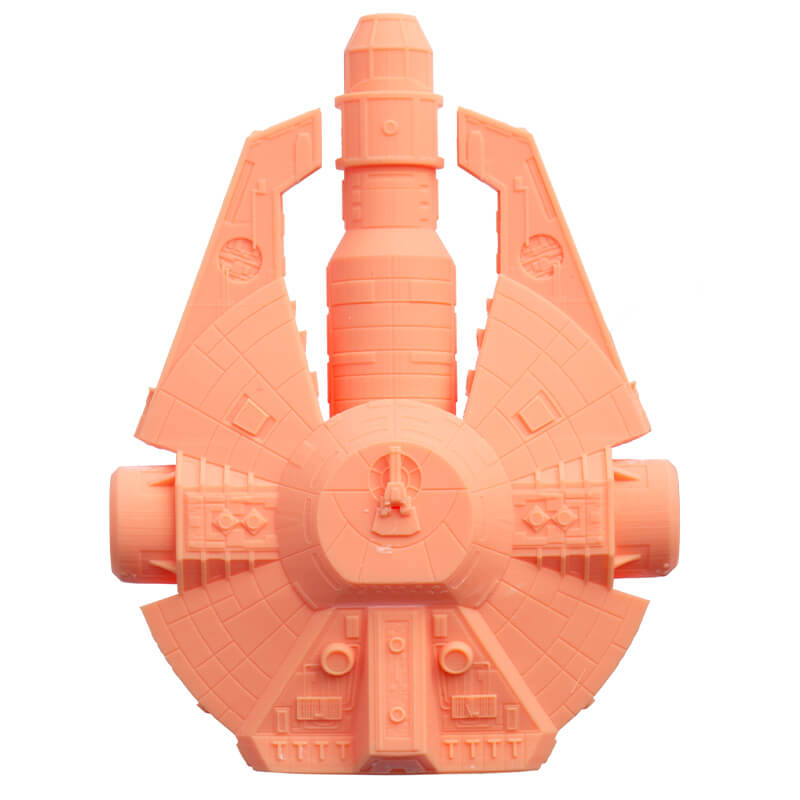

2.6, Shoes sole

3D printings, along with the printing materials, are now shaping the global footwear industry by introducing new possibilities in footwear engineering. As a result, footwear manufacturers are now creating new and innovative shoe designs, successfully addressing the ever-growing demand for customization.

As per the latest market report, the global footwear 3D printing industry is projected to become a USD 9 billion revenue-making industry in the coming ten years. On the other hand, the 3D-printed footwear segment is forecasted to become one of the largest 3D-printed consumer product segments by the end of the year 2030.

The recent development in 3D printable materials and resins has open doors for different applications. The progress is greatly triggered by a perfect collaboration between footwear brands and material providers.

For instance, Carbon is working with Adidas to come up with the elastomeric polyurethane material. This material is used in FutureCraft sneakers from Adidas. On the other hand, New Balance has been working with Formlabs to create high-quality and high-performance 3D printing materials that can be used in more footwear in the coming days. They also have developed rebound resins and a photopolymer resin that can be used to create robust lattice and springy structures.

No matter what types of shoe people want, using resins and 3D printing, you can easily create shoe soles that will match their requirements. In fact, the molds can be produced within a few hours.

It’s time to witness the innovative designs

3D printed midsoles made of resins can be very durable than other materials. You can also go for some unique patterns, like patterns of lattice structures that will make the shoes more comfortable to wear.

With this technology, brands can now explore and implement new designs as well as features for their shoe. Traditionally. Midsoles are made as a solid piece. But now, shoe performance can be enhanced with the help of the best quality resin 3D printing material. By tuning multiple areas of a midsole, you can effectively optimize cushioning properties.

How 3D Printing Resin is applied to 3D printers

3.1, Printer that matches resin – resin 3D printer

Resin 3D printers can be used to create different 3D-printed objects normally or upside down, based on how the components are positioned inside the 3D printers and the position of the build platform. Such printers use resins to create models by curing the liquid resins through a light source. Now, let’s talk about different types of resin 3D printers and how they work.

3.2, Printing principle of resin 3D printer

3.2.1, LCD 3D printer

If you compare the LCD 3D printers with the SLA or DLP 3D printers, you will find the LCD 3D printers as an ideal machine for different applications. For example, if you are looking for the best 3D printer for sole shoe production, jewelry production, and to make animated figures, you can use an LCD 3D printer. Unlike DLP 3D printers, an LCD 3D printer uses a high-quality LCD panel instead of DMD chips to process the light source.

During this printing, a light source is illuminated on the LCD panel. The LCD panel functions as a mask and processes the light. The light then cures the resins based on the model’s design. The printing process is carried out utilizing the digital mask, the UV light source, and layer by the layer printing process.

LCD printers are good for producing high-quality products with super fine details. Besides, the printing process is much faster than other machines. So, most industries are now using these machines for printing.

3.2.2, DLP 3D printer

Speaking about DLP- Digital Light Processing, this printing process was introduced in 1987 by Larry Hornbeck. However, it was not designed for 3D printing. But now, it has become a powerful manufacturing technology. Speaking about the DLP printing technology, such printers are working by utilizing a DMD projector. The projector utilizes a light source to cure the photosensitive resin and makes products by creating one layer at a time. The projector cures the layers and solidifies the liquid resin based on the product design.

Once done with the first layer, the printed part is pulled up by a few inches, and the printer creates the next layer. The process continues until the product is completed.

Such printing is useful in different industries, including jewelry making and dentistry industries. Besides, some shoemaking companies are also using DLP printing. Different studies have proved that DLP printers are very fast and can easily print complex or intricate designs. But the parts may not demonstrate better mechanical properties, and sometimes the items will not last long.

3.2.3, SLA 3D printer

SLA- Stereolithography is quite popular for the realization of particular filigree as well as precise objects. The printing technology is very accurate, and a laser light source is used to harden transparent 3D printing material. The objects are made through a layer-by-layer process. The layers can be very thin; for example, the printers can create 25micron of the layer. The light source solidifies the liquid resin through a photo-polymerization process. Currently, in 3D printing, SLA is the accurate 3D printing technology. Under this, you will find two major types of SLA technology, projection-based and laser-based. Now, let’s talk about its working process.

First, the 3D model is created using a slicing program. A resin tank is filled with high-quality liquid 3D printer flexible resin. Then a build platform is lowered into the tank, and the UV laser created one layer. In this printer, the laser source is positioned utilizing Galvanometers. These are sets of tiny mirrors that reflect and rotate the laser. The resin hardens, creating a single layer of the 3D model. The process is repeated, and the print platform is raised until the model is finished.

Advantages of LCD printing

- The printing process is very accurate and cost-effective as it doesn’t include the laser galvanometer.

- Besides, it offers faster printing using surface forming light source printing techniques. The entire model can be printed at a single time.

- Different types of resins can be used in LCD printing.

Advantages of SLA printing

- The processing accuracy level is quite impressive.

- It can be used to create complex shapes and parts. You can create toys, mobile phones, hollow parts, and more.

- The SLA printing can easily process around 0.1 to 0.15mm of layered scanning.

- With thin walls, you can witness fine details on the finished products.

Advantages of DLP printing

- It includes three major characteristics, such as a perfect native contrast, secure optical path, and miniaturization of printing machines.

- As the chip uses an advanced mechanical process, you can get the expected native contrast ratio.

- The DLP projectors function on the reflective principle. So, this printing is good for your eyes.

While choosing a 3D printer, make sure that you have checked the types of resins that 3D printers can support. If you are looking for the most advanced machine, you can always go for an LCD 3D printer.Dreambot3D

How to Choose a High-quality 3D Printing Resin Manufacturer

For the best result in your 3D printing, you need to buy the best photosensitive resin from the reputed and trusted 3D printing resin suppliers. But choosing the right manufacturer can be a challenging task as the market has a lot of options. To help you out, we have written down some tips for you. Have a look.

4.1, Check the brand reputation

Before choosing the manufacturer, you should always check the brand’s reputation. For this, you can go through the customer’s reviews given by previous buyers. Besides, you can check the sites that contain reviews of different brands. It is also advisable to choose an old brand with years of reputation in the industry.

4.2, Go for flexibility

Well, this suggests the types of resins the supplier can offer you. You need to make sure that the company can offer you different options so that you can buy anything under one roof. Besides, the supplier must have a flexible return option so that if you get a defective product, you can easily return that.

4.3, Pay attention to details

Look for the manufacturers with a lot of information about the resin printer resin upfront. You should look out for specifics. Specifics about their resins will hold the suppliers more accountable. Always choose a supplier who offers every single detail about their resins.

4.4, Put safety first

Your 3D printing resin supplier must offer clear and easy-to-understand printing settings, for example, information about fan speed, nozzle temperature, bed surface, and other resin-specific considerations. Clear instructions will help you in setting the machine for the resins.

4.5, Select the most cost-effective

Choose a 3D printing resin supplier who can offer you quality resins at affordable prices. Even though the cost of the resins can more if you search, you can find cheap 3D resin. Besides, make sure that the resins come in properly sealed bags to keep them fresh and protected from UV light.

4.6, Why choose Dreambot3D filament

One of the major reasons to buy 3D printer resins from Dreambot3D is you will witness the best quality products at affordable prices. Whether you are an amateur designer, a 3D printing hobbyist, or a large company making prototyping, Dreambot3D has the best filaments and resins for your 3D printing projects.

Dreambot3D is a one-stop solution for all your 3D printing requirements. We believe that 3D printing is a massive industry and a full-time occupation. To support this industry, we are here with the entire gamut of 3D services. We deal with all types of 3D printers, including FDM and LCD 3D printers and 3D printer resins. We also conduct workshops and training to spread awareness about 3D printing.

So, as a customer, there is no need to waste your time searching for multiple vendors for your various 3D printing requirements when you have Dreambot3D by your side.

Offering solutions through our dedicated staffs

Unlike other companies, Dreambot3D has established a dedicated support staff to offer quality post-sale service to all our valuable customers. They are equipped with all the required training and tools to offer seamless support.

Faster delivery

Our order to ship time is quite faster than other suppliers. So, you can trust Dreambot3D for on-time delivery. All the products are shipped to different domestic locations affordably and quickly.

Our filaments and resins help the 3D printer users to witness best-in-class performance through superior polymer chemistry, vacuum-sealed packaging, and superb dimensional tolerance. Dreambot3D is highly committed to expanding the product line in terms of colors and materials.

Besides, we will also support our customers with top-notch services. Don’t think much and choose Dreambot3D, one of the leading 3D printing resin suppliers for your resin or filament requirements.

Some frequently asked questions about 3D Printing Resin

If you still have some doubts regarding 3D printing liquid resin, take a look at this FAQs section. Here we have covered some important questions related to resin 3D printing material and their usage. Have a look.

What resins are available for 3D printing?

Even though filaments and FDM 3D printing are quite popular in the 3D printing industry, resin 3D printing is also becoming a mainstream manufacturing process. The reason behind this is the speed of the process and the availability of different types of resins. Just like filaments, you will get a lot of options while buying LCD resin. For example, you can buy standard rigid resin, ABS resin, high hardness & toughness resin, jewelry casting resin, elastic or flexible 3D resin, dental casting & guide resin, high-temperature resin, and more. However, while buying, choose the best 3D printing resin supplier to get the highest-quality materials at affordable prices.

What is the best resin for 3D printing?

While using printer 3D resin, you will want to 3D-print the part or model quickly, without losing the toughness or becoming brittle. This is where you can trust the photopolymer resin for 3D printing or UV resin. The resin reacts to light and is a durable plastic polymer. What’s more? It is also a good resin for beginners as UV resin is very easy to use and doesn’t require any mix and measures. In fact, you can use the UV resin right from the bottle. Another best thing about this resin is, it cures much faster than other types of resins. So, you can complete your cast projects quickly. Try out this now.

Can you use any resin in a 3D printer?

Some resins can be used manually, and some are used in 3D printers. While buying, make sure that the resin is designed for the 3D printers. You can ask the 3D printing resin supplier for that. However, all most all the UV resins can be used in a 3D printer.

Is 3D printed resin strong?

Yes, not just parts made of filament are strong. You can create durable and strong models and functional features using tough 3D resin. As per some studies, 3D-printed parts made of tough resin can demonstrate a tensile strength of up to 55.8 MPa, and the modulus of elasticity can be around 3 GPa. This clearly shows that resin printing parts will be shatter-resistant, sturdy, and functional. In fact, in some cases, tough resin is used to make rugged prototypes.

How long do resin 3D prints last?

In general, the 3D-printed part can last for years and will not break down under normal use. However, they can lose their strength over time. Every item com with an expiry date and resin 3D-printed parts may degrade under specific harsh conditions. However, to keep the models last longer, you can use some specific resins such as high temperature 3D printing resin or tough resin.

Do resin 3D printers smell?

Resins, such as castable 3D resin or UV resin, can create fine details. But they have a significant drawback. No matter what type of 3D printer you are using, be it an LCD, DLP, or SLA resin printer, you will encounter a strong smell while printing resins. They release VOCs- Volatile Organic Compounds during the curing process that are not good for health. So, it is advisable to use a fully enclosed 3D printer and a well-ventilated place for resin 3D printing.

How long can I leave resin in the printer?

If you keep the LCD resin away from the UV light, then the uncured resin can be left in the tank for many weeks. The perfect place to store your uncured resin is a dark and cool place. But if the environmental condition is not favorable, the photopolymer resin for 3D printing may last for a few hours or up to 2 days.

Can I leave resin in my printer overnight?

Yes, you can, but make sure that the printer is located in a cool and dark place. Any light source can harden your uncured resin, making it unusable. You can cover the resin tank with a dark cover. But it will be better to transfer the unused resin from the printer into a bottle. This way, you can easily maintain your 3D printer as well as the resin.

Are resin printers dangerous?

As per the experts, UV resins or photosensitive resin used for 3D printing is toxic. Anybody parts exposed to the resins can be harmed. Besides, improper use of this 3D printing material can harm animals as well as the environment. It is advisable to use a good-quality and enclosed LCD 3D printer. Some 3D printing resin suppliers are now introducing environmental and non-toxic resins. You can use them for safe printing.

Do resin printers need ventilation?

Yes, if you are using ABS resin or other types of resins in an LCD 3D printer, adequate ventilation is required. Besides, for your safety, you can use a face mask. The ventilation system will keep your surrounding air clean. But the LCD printer resin produces less smell than filaments.

How much do resin 3D printers cost?

Well, this will depend on the types of resin 3D printers you are buying and the features you want. However, the costs can range from USD1000 to USD 5000. But if you compare, you will find that resin 3D printers are cheaper than the FDM 3D printer. Besides, a single resin 3D printer is enough to print various types of resins.

How strong is 3D printed resin?

It is a fact that the standard resins are brittle compared to other materials used in 3D printing. So, such resins are not used for outdoor use or stressed parts. But you can use a tough 3D resin that is specifically formulated for durable and stronger parts. Such resins can offer a better level of tensile strength.

How durable is 3D printed resin?

Resins, such as tough and high hardness resin, can mimic ABS plastic’s mechanical properties and feel. Such resins are specifically designed for applications that need a material that can easily withstand a higher level of stress and strain. Objects printed using high hardness or toughness resins can produce around 56 MP of tensile strength. So, if you don’t have filaments, you can use this resin. With a perfect balance of compliance and strength, the durable resin is ideal for functional and robust prototypes. The objects can easily withstand wear and tear.

What material is SLA resin?

SLA resin is procced through the stereolithography method. SLA resins are light-reactive thermoset materials. When these are exposed to a particular wavelength of light, the molecules react, and short molecular chains join together. The reaction polymerizes oligomers and monomers into solid-state, helping you in creating hard models.

How much resin do I need for 3D printing?

To understand this, let’s take an example. With 1 liter of LCD printer resin, you can 3D print up to 150 tabletop minis or figurines with 1 inch of height. On the other hand, if you are 3D printing 1cm x 1m of cubes, around 500 cubes can be a 3D printer. So, the resin requirement for 3D printing will depend on the quantity and size of the items you want to 3D print.

What happens if you touch uncured resin?

Well, you may not witness any reaction at first. But when an uncured resin comes into contact with skin, gradually, you will face skin rashes or irritation. In some cases, people may face contact dermatitis, a type of skin rash that can develop allergies. So, be careful while using resins. Always use high-quality resins brought from reputed 3D printing resin suppliers.

Can you use a resin printer indoors?

Can you use a resin printer indoors?

What is LCD resin?

As the name suggests, LCD resin or LCD castable resin is used in LCD 3D printing. In this process, an LCD panel is used as a mask and that developer the curing pattern. The resin will become hard plastic on the areas where the light hits. LCD resins have faster-curing abilities.

How does LCD resin printing work?

The process is very simple to understand. All the LCD 3D printers use UV rays to cure the resin. The UV rays are moved through an LCD panel that works as a mask and flashes the design on the resin. The light then hardens the resin, creating models in the layer. In LCD 3D printing, the entire model design can be flashed at the same time.

What is an LCD printer?

LCD 3D printing is somewhat the same as DLP 3D printing. The machines also flash complete layers at the resin tank. However, in LCD 3D printing, UV light comes from LEDs and shines through the LCD panel instead of a projector. The LCD panel acts as a mask, reveals only the pixels required for the current layer.

What's the difference between SLA and LCD?

To understand this, let’s talk about these 3D printing processes in detail. SLA or stereolithography 3D printing is quite popular and an extensive strategy in additive manufacturing. This type of printing operates by utilizing a high-powered laser to solidify liquid resin located in a tank to create the desired 3D form. In simple words, this printing method transforms photosensitive resin into 3D solid plastics utilizing photo-polymerization. Now, speaking about LCD, it is known as the Liquid Crystal Show. As the name suggests, this is a liquid crystal projector. The machine is environment-friendly and can solidify resins using UV light that moves through the LCD panel. In the 3D printing industry, LCD 3D printers can be considered the best machine and can offer faster printing results.

How does a resin printer work?

All the resin 3D printers work by using a light source, especially a UV light source. The light is flashed through a mask or LCD panel. This projects the design on the resin. When the resin comes into contact with light, it solidifies, creating the object. Compared to FDM 3D printing, resin printers are quite fast, and you can get high-detailed products.

What's the difference between DLP and SLA?

DLP means Digital Light Processing and has some common similarities with the stereolithography 3D printing process. In this printing process photopolymers, resins are used. In general, the DLP 3D printing technology utilizes a traditional light source, such as the arc lamp, along with a liquid crystal display panel. In the printing process, the polymer or printing material is exposed to the UV ray in a safe way. The process begins with sending the 3D image file to the printer. After that, a projector located under the resin tank projects the 3D image’s slices on the resin layers. The layer that is exposed to the light hardens. This process continues until the 3D model is completed. SLA- Stereolithography is the oldest 3D printing technology, but you can still find some 3D printers with this printing technology. Different from the DLP printers, the SLA printers utilize a laser beam to harden the polymer. In the printing process, the printer directs the laser to galvanometers that then direct the lasers to accurate X and Y coordinates. The laser beam moves across the print and hardens the photopolymer. This process breaks the design into different coordinates for every layer along the lines which are transferred to the galvanometers.

How does a 3D printer connect to an LCD?

Tan LCD panel can be connected with the 3D printers using cables and then attaching the cables to the printer’s motherboard. After attaching it, you need to set up the LCD panel functionality using the software. Once done, you can use the LCD panel while printing.

What is DLP resin?

Digital Light Processing resin cures under the vat polymerization process. Under this process, the liquid or photopolymer resin solidifies under light or UV light sources. You can use different types of DLP resins to create a 3D-printed model.

What does LCD stand for in 3D printing?

In 3D printing, LCD stands for Liquid Crystal Display. LCD 3D printing is relatively faster than other resin 3D printing. In fact, it is also quicker than the FDM 3D printers. When UV rays pass through the LCD panel, the entire image is projected on the resin tank. As a result, the whole model can be created at the same time.

What is DLP resin made of?

DLP resin is made of oligomers or monomer photopolymers that harden when you flash the light on the resin. It may be noted that resins different from plastic as plastic has more synthetic polymer. On the other hand, resin comes with some natural properties derived from plants.

Why does an LCD printer generally print faster than an SLA printer?

The primary reason behind this is LCD 3D printers can flash a single image of a layer throughout the platform simultaneously. But in the case of an SLA 3D printer, it flashes a single point. So, if you want faster production results, go for an LCD 3D printer.

What is SLS 3D printing?

SLS- Selective Laser Sintering is a popular AM-Additive Manufacturing technology that utilizes a powerful laser to sinter polymer powder small particles into a solid form based on the design of the 3D object. SLS is quite popular in the manufacturing and engineering industry.

Are resin printers better?

Some people think that FDM printers are better in the 3D printing industry. However, the technological advancement in this industry also has made resin printers more powerful. These printers can also be used to produce durable and robust parts using tough 3D resin. Besides, there is high temp resin for 3D printer, using which you can make 3D models that can withstand a higher temperature. So, resin printers are better.

Is casting resin strong?

As per some studies, casting resin or castable 3D resin may absorb the impact or bend, but it will not break. The resin is designed and formulated to be indestructible. Some users even have found casting resin quite stronger than the polyester material.

Is resin as strong as PLA?

In the case of layer adhesion, PLA can sustain around 8 kg, and PETG can hold around 5.9kg. However, the tough resin can hold up to 10 kg. So, the resin is stronger like PLA and other filaments.

How loud are resin printers?

FDM- Fused Deposition Modeling printers come with multiple motors and fans, so they generate noise while functioning. However, most resin printers come with fewer fans and motors. So, you won’t face noise issues and would enjoy a quieter printing experience.

Are resin 3D prints brittle?

Yes, in some cases, cures 3D printing resins can be more brittle, and they may not tough like nylon or ABS thermoplastic. But the resin models can be harder than filaments.

Can you touch resin?

It is advisable not to touch the resin if you are not wearing a protective glove. Wash your body parts or hands properly that may contact the resin using a cleanser or soap. Don’t use any solvents. UV cured resins can lead to a skin infection.

Is UV resin better than epoxy resin?

Speaking about the epoxy resins, they are two-part resin. They include resins and hardening compounds. The combination of these two components creates a chemical reaction that formulates a mixture and hardens over time, offering you a transparent and glossy surface. Coming to the UV resins, or photosensitive resin, it can become hard within a few minutes using a UV light. This resin can also harden under the sun’s lights. While using this, you don’t need to use any hardening compounds. But UV resin is a little costlier than epoxy resin. If you want to make jewelry, choosing UV resin can be the best option. For a more significant project, epoxy resin will work well.

Is there a non-toxic resin?

Yes, you can now buy non toxic 3D printer resin as different resin manufacturers have now started introducing such resins. For example, ArtResin is approved and recognized by the ASTM- American Society for Testing and Materials. It is safe to use resin as it meets the safety standard D-4236. This is perfect for home use.