3D Printer SLA

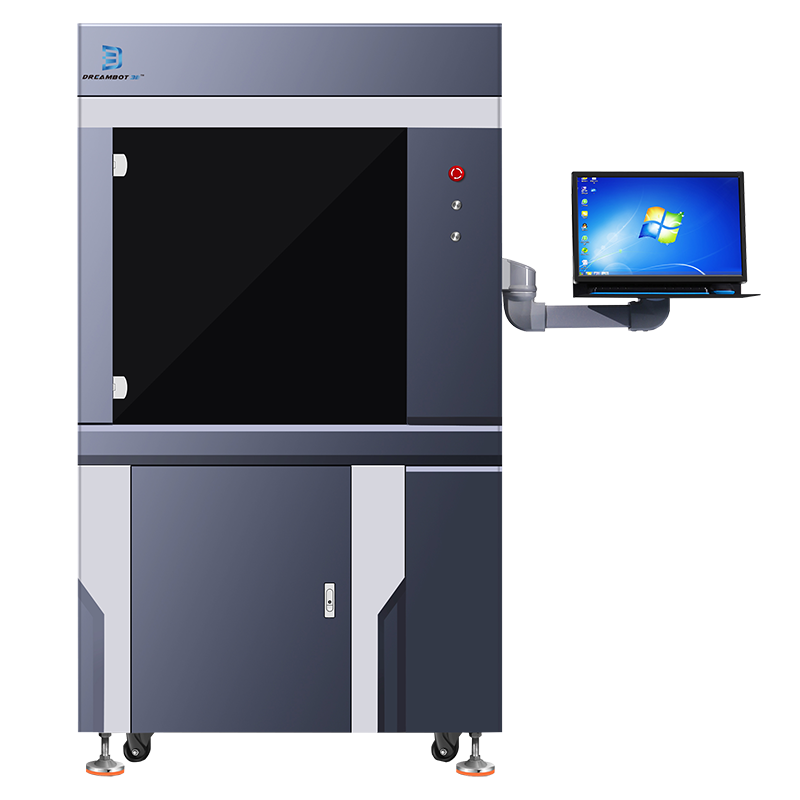

SLA-600 3D Printer

- Print size: 600 (x) * 600 (y) * 400 (z) mm

- 0.025-0.3 mm print layer thickness and 85HM laser spot size

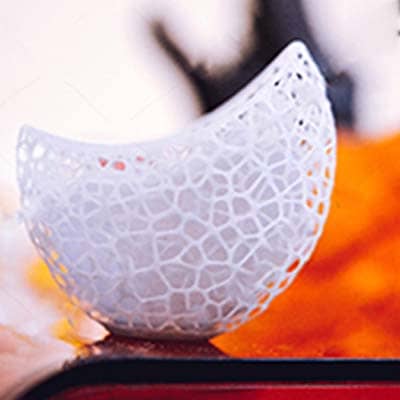

- It is possible to create prototypes of extremely high quality, with fine features (thin walls, sharp corners, etc.) and complex geometry.

Dreambot3D 3D Printer SLA

Dreambot3D SLA 3D printer offers excellent printing precision and smooth surface quality, making it easy for post-processing (0.05mm-0.1mm). This makes it a perfect choice for industrial applications.

SLA 3D printing features fast forming speeds, with a comprehensive printing speed over 10 times faster than FDM, and it supports larger build sizes with high production efficiency.

It is highly compatible with various materials, supporting resins with different properties such as high transparency, color, high-temperature resistance, and high strength. The resin tank has a large capacity, capable of holding 150-300KG of resin in one go.

| laser system | Laser type | Two-stage tube solid state laser |

| wavelength | 355nm | |

| power | 3000mw | |

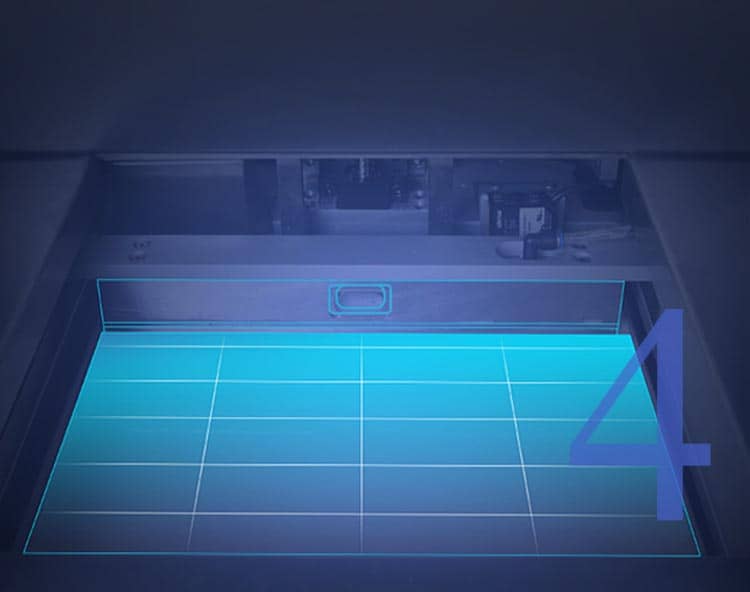

| Maximum molding space (XYZ) | 600*600*400 | |

| Printing layer thickness accuracy (Quick production layer thickness) | 0.1mm-0.15mm | |

| Make tight layers thick | 0.05mm-0.1mm | |

| optical scanning system | Spot diameter | 0.1mm-0.12mm |

| Scanning speed | 5.0m/s (Standard) 12.0m/s(maximum speed) | |

| Scanning galvanometer | High speed galvanometer | |

| Recoating system | Intelligent vacuum adsorption coating system | |

| Accuracy of lifting system Vertical resolution | 0.0002mm | |

| Repeated positioning accuracy | ±0.01mm | |

| Resin cylinder capacity | 250/480/890 KG | |

| software environment | Operating system | WINDOWS7/10 |

| Control software | QUBEWARE PRO | |

| File format | STL & SLC | |

| Network compatibility | 10/100m Ethernet card access | |

| operating environment | Operating temperature range | 25-30℃ |

| Operating humidity range | No more than 40% | |

| Machine size (W*D*H) | 1250*1310*2100 | |

| Machine weight | 880KG(not including resin weight) | |

| Power supply | 200~240V AC 50/60HZ,16Amps | |

| Shelf life | 12 months |

- Laser controller

Professional optical path design, greatly improve the utilization of laser power, ensure the printing quality and efficiency.

- Imported servo system

Servo drive and servo motor precise coordination, effectively ensure Z axis accurate speed regulation and positioning

- Laser liquid level sensor

Intelligent detection of common resin and transparent resin function, consumable replacement save time and effort, avoid tedious sensor adjustment work.

- Laser power detection device

Laser power online measurement, automatic setting of process parameters, to ensure X,Y,Z dimensions and positioning accuracy

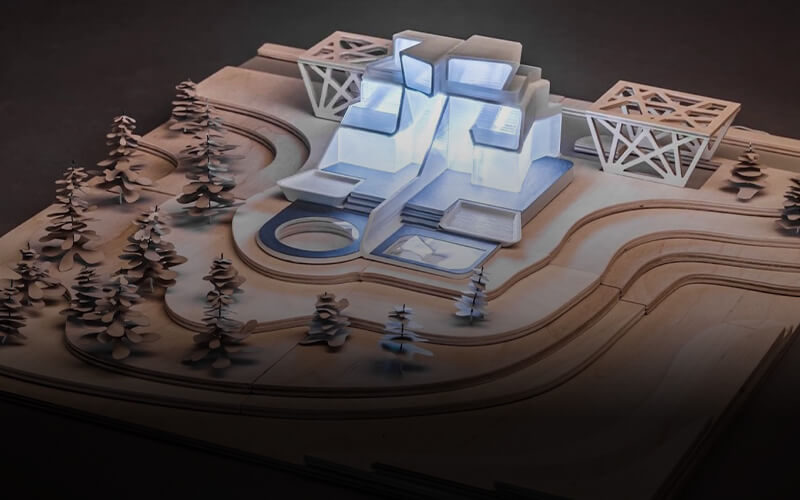

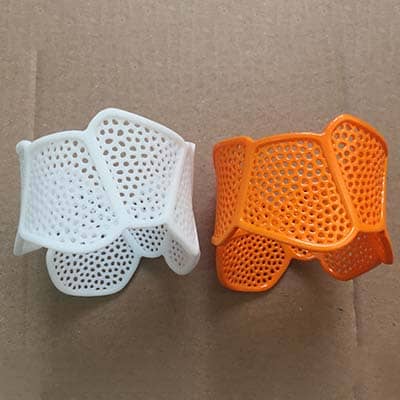

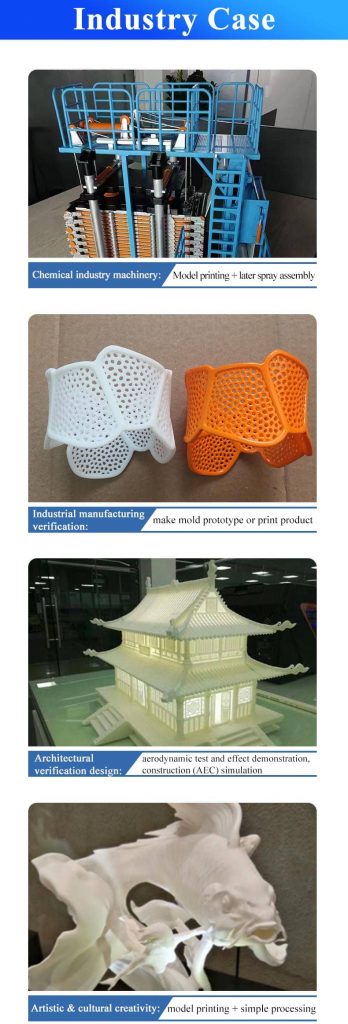

Application of 3D Printer SLA

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

6 points why choose us

Large Volume High Precision

600X600X400MM printing space for greater productivity and flexibility. Up to 0.05MM accuracy level, can produce a variety of complex structure of precision parts and assembly parts factory.

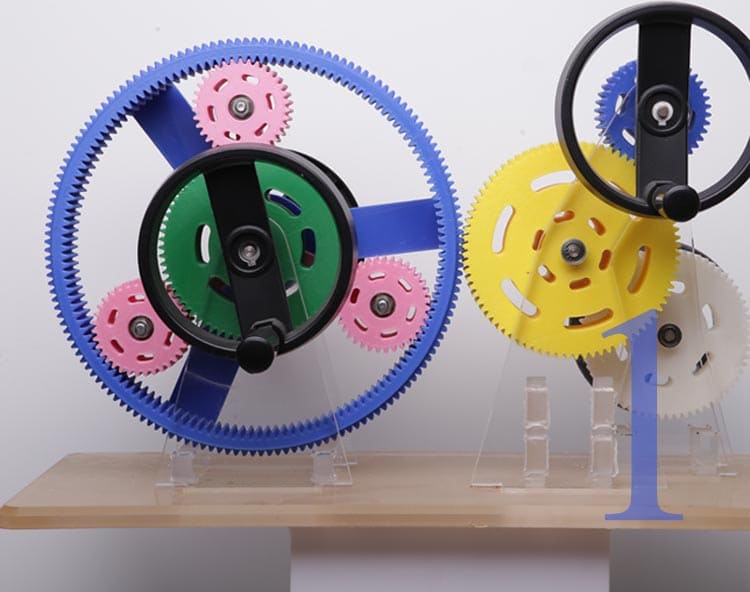

variable light spot technology

Core technology, free switching variable spot mode, significantly improve the printing efficiency.

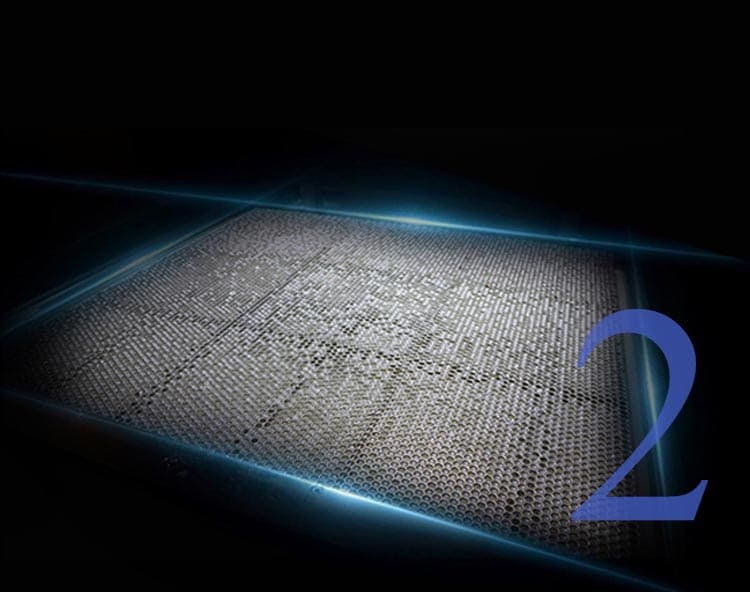

negative pressure adsorption coating system

Auto liquid level adjustment eliminates the fluctuation of liquid surface, and the thickness of laying layer can be accurate to 0.05MM, which greatly improves the uniformity of the resin printing surface.

Negative pressure adsorption automatic coating scraper

Automatic coating scraper, during the printing entity through the automatic coating device can make the surface material of the preprint layer more smooth, the negative pressure adsorption design makes the cavity of the automatic coating scraper filled with resin well during the coating, to ensure that the surface material of the preprint layer is smooth and uniform after coating.

Original imported cell

Stable and durable, continuous printing for 200 hours without pressure. It can effectively improve the printing accuracy and prolong the service life of the printer.

Fine support is easily removed

The support is only 0.8mm and can be easily removed after printing.

More 4K 3D printer

Industrial SLA 3D Printer utilizes a 355nm wavelength laser, offering high printing precision

ME-192 LCD 3D Printer

The ME-192 is used for high precision printing for all sizes of printing. It adopts high definition pixels for printing.

DB-550 LCD 3D Printer

The DB-550 is used for printing large 3D objects. It is used by industries that require printing large complex objects like prosthetics.

Dreambot3D 3D Printer SLA FAQ

- Technology:

SLA uses a laser to cure liquid resin into solid layers, offering high precision and smooth surface finishes.

FDM involves extruding melted plastic through a nozzle, building layers to form objects.

Precision and Surface Quality:

SLA is more precise, producing finer details and smoother surfaces.

FDM generally has a rougher finish and lower resolution.

- Materials:

SLA supports a variety of resins, including transparent and high-strength options.

FDM uses thermoplastics like PLA and ABS, offering a wide range of material choices.

- Speed:

SLA can be slower due to the curing process.

FDM is typically faster for simpler designs but slower for complex geometries.

- Applications:

SLA is ideal for detailed prototypes, dental models, and jewelry.

FDM is commonly used for functional prototypes, end-use parts, and educational purposes.

- Material Type:

PLA is a biodegradable thermoplastic derived from renewable resources like cornstarch, used in FDM (Fused Deposition Modeling) 3D printing.

SLA resins are liquid photopolymers that solidify when exposed to a laser or UV light.

- Applications:

PLA is widely used for basic prototypes, educational purposes, and consumer products due to its ease of use.

SLA resins are favored for highly detailed models, dental and medical devices, and other applications requiring fine surface finishes and high precision.

- Surface Quality:

PLA produces relatively rougher surfaces with visible layer lines.

SLA offers smoother, higher-resolution finishes with finer details.

- Environmental Impact:

PLA is more environmentally friendly due to its biodegradability.

SLA resins are not biodegradable and require careful handling and disposal.

These distinctions highlight their suitability for different 3D printing needs and applications.

Layer by layer, liquid resin is cured into solid objects using a laser in the SLA (Stereolithography) 3D printing process. Prints with excellent resolution and a smooth surface after this technique are very detailed. Prototypes, dental models, jewelry, and other applications demanding fine detail and accuracy are often produced using SLA. Depending on the particular application, the resin used in SLA printing may have a variety of qualities, including high strength, flexibility, or temperature resistance.

In 3D printing, SLA (Stereolithography) builds a 3D item one layer at a time by tracing and solidifying layers of liquid resin using a laser. A vat of liquid resin that is photosensitive is where the process starts. A computer-guided laser beam follows the contours of each layer, solidifying the resin wherever it comes into contact with it. The construction platform descends a little bit to make room for the formation of the next layer when each layer is finished. Until the whole thing is finished, this procedure is repeated.

When compared to other 3D printing techniques like Fused Deposition Modeling (FDM), items produced by SLA (Stereolithography) 3D printing are often highly sturdy. The way the layers are fused together gives SLA-printed components their strength; the laser solidifies the resin into a structure that produces fine detail and strong layer adhesion. But the kind of resin that is used also affects the part’s strength; certain resins have a high tensile strength, while others are more brittle.